Co-polymer polystyrene offers enhanced impact resistance and durability compared to homopolymer polystyrene, making it suitable for applications requiring greater toughness. Homopolymer polystyrene is more rigid and provides excellent clarity, ideal for packaging and disposable cutlery where stiffness is essential. The choice between co-polymer and homopolymer polystyrene depends on the balance between mechanical strength and optical properties needed for the specific application.

Table of Comparison

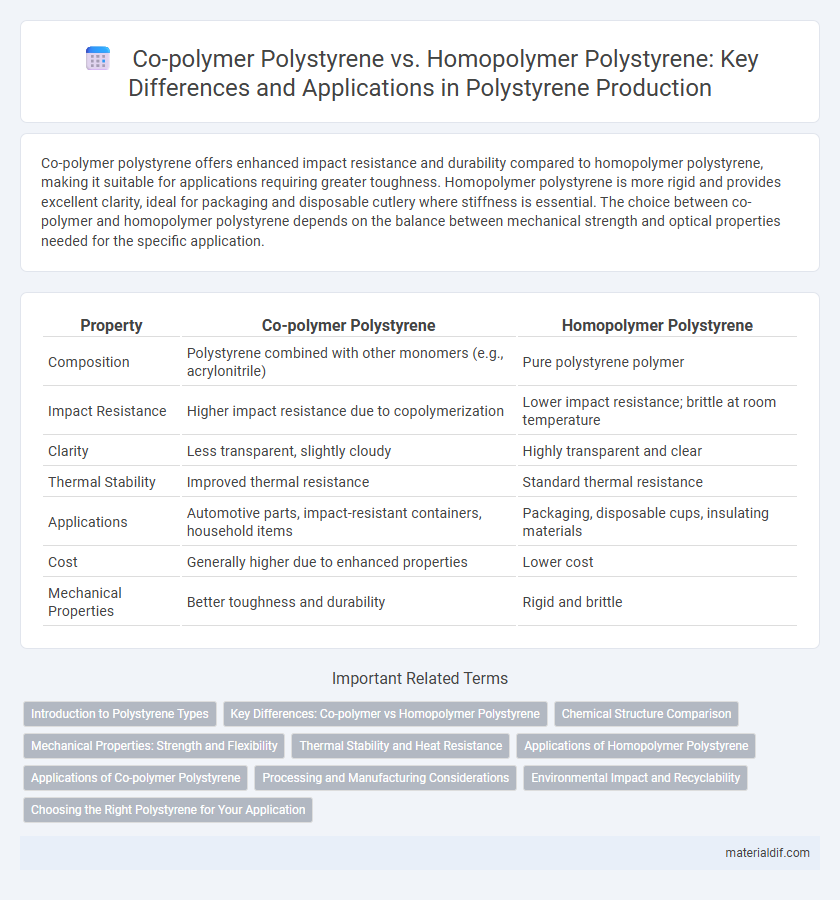

| Property | Co-polymer Polystyrene | Homopolymer Polystyrene |

|---|---|---|

| Composition | Polystyrene combined with other monomers (e.g., acrylonitrile) | Pure polystyrene polymer |

| Impact Resistance | Higher impact resistance due to copolymerization | Lower impact resistance; brittle at room temperature |

| Clarity | Less transparent, slightly cloudy | Highly transparent and clear |

| Thermal Stability | Improved thermal resistance | Standard thermal resistance |

| Applications | Automotive parts, impact-resistant containers, household items | Packaging, disposable cups, insulating materials |

| Cost | Generally higher due to enhanced properties | Lower cost |

| Mechanical Properties | Better toughness and durability | Rigid and brittle |

Introduction to Polystyrene Types

Co-polymer polystyrene incorporates different monomers with styrene to enhance impact resistance and thermal stability compared to homopolymer polystyrene, which consists solely of styrene units resulting in higher rigidity and clarity. Homopolymer polystyrene is commonly used in applications requiring transparency and stiffness, while co-polymer variants are preferred for durable and impact-resistant products. The choice between co-polymer and homopolymer polystyrene depends on the specific mechanical and optical property requirements of the end-use application.

Key Differences: Co-polymer vs Homopolymer Polystyrene

Co-polymer polystyrene incorporates additional monomers such as acrylonitrile or butadiene, enhancing impact resistance and thermal stability compared to homopolymer polystyrene, which consists solely of styrene monomers. Homopolymer polystyrene offers higher clarity, rigidity, and ease of processing but has lower impact strength and brittleness under stress. Selection between co-polymer and homopolymer polystyrene depends on application requirements for durability, transparency, and mechanical performance.

Chemical Structure Comparison

Co-polymer polystyrene incorporates different monomers such as acrylonitrile or butadiene within its polymer chains, resulting in a heterogeneous molecular structure that enhances specific properties like impact resistance and chemical stability. Homopolymer polystyrene consists solely of styrene monomers, producing a consistent, linear polymer chain with rigid structural characteristics and higher transparency. The presence of varying monomer units in co-polymers disrupts the regularity found in homopolymers, significantly influencing thermal, mechanical, and chemical behavior.

Mechanical Properties: Strength and Flexibility

Co-polymer polystyrene exhibits enhanced flexibility and impact resistance compared to homopolymer polystyrene, which is characterized by higher rigidity and strength. The incorporation of rubber or other monomers in co-polymer polystyrene disrupts the polymer chain regularity, improving toughness and elongation at break. Homopolymer polystyrene's superior tensile strength and stiffness make it suitable for applications requiring dimensional stability and structural integrity.

Thermal Stability and Heat Resistance

Co-polymer polystyrene exhibits enhanced thermal stability and heat resistance compared to homopolymer polystyrene due to the incorporation of comonomers that disrupt the regular polymer chain structure. This molecular modification improves the material's ability to withstand higher temperatures without deforming or degrading. As a result, co-polymer polystyrene is preferred in applications requiring superior thermal performance and durability under elevated heat conditions.

Applications of Homopolymer Polystyrene

Homopolymer polystyrene is widely utilized in packaging materials, disposable cutlery, and insulation due to its rigidity and ease of molding. Its optical clarity and resistance to acids make it ideal for food containers and laboratory equipment. Unlike copolymer polystyrene, homopolymer variants offer superior hardness, which suits applications requiring dimensional stability and durability.

Applications of Co-polymer Polystyrene

Co-polymer polystyrene exhibits enhanced impact resistance and chemical stability compared to homopolymer polystyrene, making it ideal for applications requiring durability and toughness. It is widely used in packaging, automotive components, and consumer goods where improved mechanical properties and resistance to environmental stress are critical. Co-polymer variants also find applications in medical devices and household appliances due to their superior strength and versatility.

Processing and Manufacturing Considerations

Co-polymer polystyrene offers enhanced impact resistance and flexibility compared to homopolymer polystyrene, making it more suitable for applications requiring higher mechanical durability during processing. Homopolymer polystyrene is easier to mold and process due to its higher rigidity and lower melt viscosity, resulting in faster cycle times and better dimensional stability in manufacturing. Processing parameters such as temperature control and cooling rates differ significantly, with co-polymers requiring precise thermal management to maintain their elastomeric properties and prevent degradation.

Environmental Impact and Recyclability

Co-polymer polystyrene, which incorporates other monomers like acrylonitrile or butadiene, typically exhibits enhanced mechanical properties but can complicate recycling processes due to mixed polymer chains, resulting in lower recyclability and potentially higher environmental impact. In contrast, homopolymer polystyrene is generally easier to recycle because its uniform polymer structure allows more efficient processing and reuse, contributing to reduced environmental footprint. Both materials pose challenges in biodegradability, but homopolymer polystyrene's simpler composition favors established recycling streams, mitigating some environmental concerns compared to co-polymer variants.

Choosing the Right Polystyrene for Your Application

Co-polymer polystyrene offers enhanced impact resistance and improved clarity compared to homopolymer polystyrene, making it ideal for applications requiring toughness and aesthetic appeal. Homopolymer polystyrene provides higher rigidity and ease of processing, suitable for products where structural stability is critical. Selecting the right polystyrene depends on balancing factors like mechanical properties, transparency, and cost-effectiveness for specific uses such as packaging, automotive parts, or consumer goods.

Co-polymer Polystyrene vs Homopolymer Polystyrene Infographic

materialdif.com

materialdif.com