Polystyrene pellets offer superior rigidity and cost-effectiveness compared to PLA pellets, making them ideal for applications requiring high strength and durability. PLA pellets, derived from renewable resources, provide better biodegradability and lower environmental impact but tend to have lower heat resistance and mechanical properties. Selecting between these pellets depends on balancing performance needs with environmental considerations.

Table of Comparison

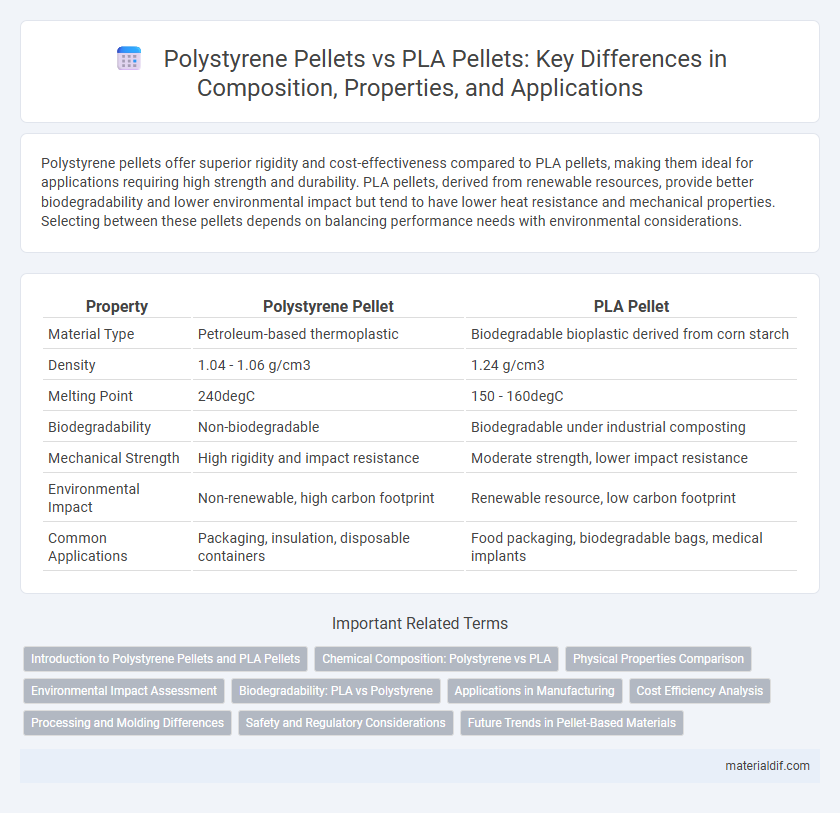

| Property | Polystyrene Pellet | PLA Pellet |

|---|---|---|

| Material Type | Petroleum-based thermoplastic | Biodegradable bioplastic derived from corn starch |

| Density | 1.04 - 1.06 g/cm3 | 1.24 g/cm3 |

| Melting Point | 240degC | 150 - 160degC |

| Biodegradability | Non-biodegradable | Biodegradable under industrial composting |

| Mechanical Strength | High rigidity and impact resistance | Moderate strength, lower impact resistance |

| Environmental Impact | Non-renewable, high carbon footprint | Renewable resource, low carbon footprint |

| Common Applications | Packaging, insulation, disposable containers | Food packaging, biodegradable bags, medical implants |

Introduction to Polystyrene Pellets and PLA Pellets

Polystyrene pellets are small, solid beads made from a synthetic polymer commonly used in packaging, insulation, and disposable containers due to their lightweight and durable properties. PLA pellets, derived from renewable resources like cornstarch and sugarcane, offer a biodegradable alternative with applications in compostable packaging and 3D printing. Both pellet types serve as raw materials in plastic manufacturing but differ significantly in environmental impact and thermal properties.

Chemical Composition: Polystyrene vs PLA

Polystyrene pellets consist primarily of styrene monomers forming a synthetic aromatic hydrocarbon polymer with a linear chain structure, characterized by its rigidity and clarity. PLA pellets are derived from polylactic acid, a biodegradable polyester made from renewable resources like corn starch, featuring a chemical structure with repeating lactic acid units containing ester linkages. The contrast in chemical composition results in polystyrene's non-biodegradability and thermal stability, while PLA offers biodegradability and compostability under industrial conditions.

Physical Properties Comparison

Polystyrene pellets exhibit higher rigidity and impact resistance compared to PLA pellets, making them suitable for applications requiring durable and stiff materials. The density of polystyrene pellets typically ranges from 1.04 to 1.06 g/cm3, whereas PLA pellets have a slightly lower density of around 1.24 g/cm3, impacting their weight and processing characteristics. Thermal properties also differ, with polystyrene having a glass transition temperature around 95degC, higher than PLA's 60degC, influencing their suitability for heat-resistant products.

Environmental Impact Assessment

Polystyrene pellets generate significant environmental concerns due to their non-biodegradable nature and persistence in ecosystems, contributing to long-term plastic pollution and microplastic accumulation. In contrast, PLA pellets, derived from renewable resources like corn starch, offer a more sustainable alternative with compostability under industrial conditions and reduced carbon footprint during production. Life cycle assessments indicate that PLA pellets lower greenhouse gas emissions and mitigate marine pollution risks compared to conventional polystyrene pellets.

Biodegradability: PLA vs Polystyrene

PLA pellets exhibit superior biodegradability compared to polystyrene pellets, as PLA is derived from renewable resources like corn starch and can decompose under industrial composting conditions within months. Polystyrene pellets, made from petroleum-based polymers, persist in the environment for hundreds of years due to their resistance to microbial degradation. The rapid breakdown of PLA contributes to lower environmental impact, making it a more sustainable option for packaging and disposable products.

Applications in Manufacturing

Polystyrene pellets are widely used in the production of rigid foam insulation, disposable food containers, and packaging materials due to their lightweight and insulating properties. PLA pellets, derived from renewable resources, are favored for manufacturing biodegradable packaging, medical implants, and 3D printing filaments, emphasizing sustainability in product design. The choice between polystyrene and PLA pellets in manufacturing depends on the required durability, environmental impact, and end-use application of the final product.

Cost Efficiency Analysis

Polystyrene pellets offer a lower material cost compared to PLA pellets, making them more economical for large-scale production. Polystyrene's manufacturing process requires less energy, reducing overall processing expenses and enhancing cost efficiency. However, the long-term environmental disposal costs of PLA pellets may offset initial material savings from polystyrene in sustainable applications.

Processing and Molding Differences

Polystyrene pellets melt at approximately 240degC, allowing for fast and efficient injection molding with high flow rates, while PLA pellets require lower temperatures around 180degC and have slower crystallization rates that impact cycle times. Polystyrene exhibits low moisture sensitivity, reducing processing defects, whereas PLA pellets need careful drying to prevent hydrolytic degradation during molding. The rigidity and thermal stability of polystyrene make it suitable for detailed molds and high-volume production, contrasting with PLA's biodegradable nature that limits high-temperature applications but favors eco-friendly processing.

Safety and Regulatory Considerations

Polystyrene pellets pose concerns due to their potential release of styrene monomers, classified as a possible human carcinogen by the International Agency for Research on Cancer (IARC), necessitating strict handling and disposal regulations under OSHA and EPA guidelines. PLA pellets, derived from renewable resources, are generally recognized as safe (GRAS) and comply with FDA regulations for food contact applications, offering a safer alternative in biodegradable product manufacturing. Regulatory frameworks emphasize minimizing exposure to polystyrene's hazardous emissions, whereas PLA's biocompatibility and compostability align with emerging environmental safety standards.

Future Trends in Pellet-Based Materials

Polystyrene pellets continue to dominate in packaging and insulation due to their low cost and excellent thermal properties, while PLA pellets gain traction driven by increasing demand for biodegradable and compostable materials in sustainable applications. Future trends indicate a shift towards hybrid pellet formulations that combine the durability of polystyrene with the eco-friendly benefits of PLA, enhancing mechanical performance and environmental impact. Innovations in pellet processing technology and recycling methods aim to improve circularity, reduce carbon footprints, and meet stricter regulatory standards in pellet-based manufacturing.

Polystyrene Pellet vs PLA Pellet Infographic

materialdif.com

materialdif.com