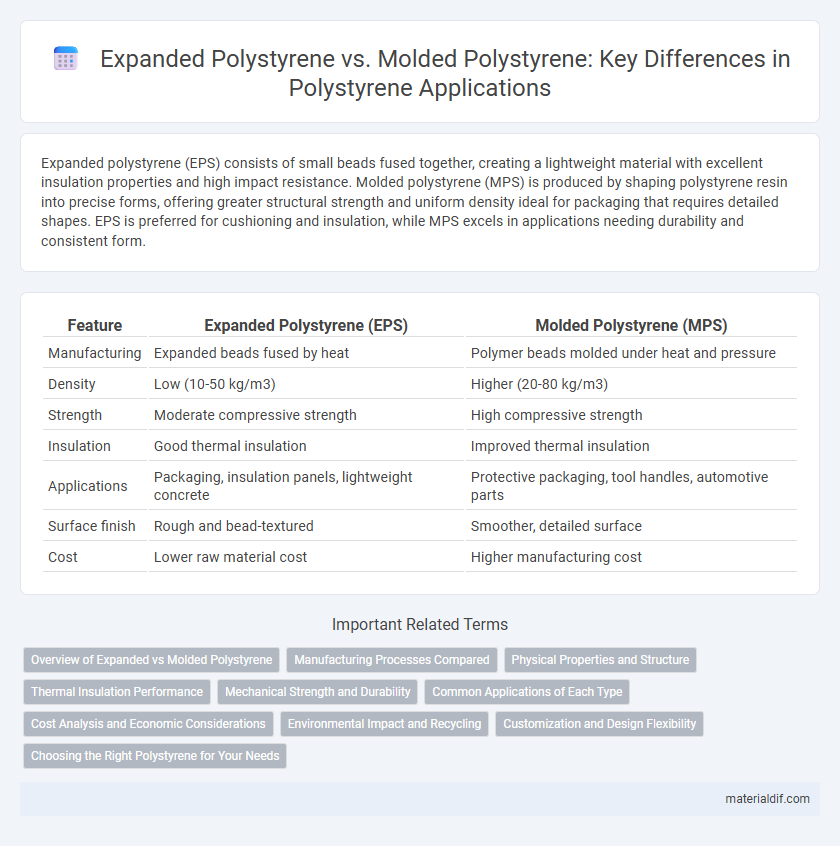

Expanded polystyrene (EPS) consists of small beads fused together, creating a lightweight material with excellent insulation properties and high impact resistance. Molded polystyrene (MPS) is produced by shaping polystyrene resin into precise forms, offering greater structural strength and uniform density ideal for packaging that requires detailed shapes. EPS is preferred for cushioning and insulation, while MPS excels in applications needing durability and consistent form.

Table of Comparison

| Feature | Expanded Polystyrene (EPS) | Molded Polystyrene (MPS) |

|---|---|---|

| Manufacturing | Expanded beads fused by heat | Polymer beads molded under heat and pressure |

| Density | Low (10-50 kg/m3) | Higher (20-80 kg/m3) |

| Strength | Moderate compressive strength | High compressive strength |

| Insulation | Good thermal insulation | Improved thermal insulation |

| Applications | Packaging, insulation panels, lightweight concrete | Protective packaging, tool handles, automotive parts |

| Surface finish | Rough and bead-textured | Smoother, detailed surface |

| Cost | Lower raw material cost | Higher manufacturing cost |

Overview of Expanded vs Molded Polystyrene

Expanded polystyrene (EPS) is a lightweight, rigid foam made by expanding pre-formed polystyrene beads with steam, resulting in a material commonly used for insulation and packaging due to its excellent cushioning properties. Molded polystyrene (MPS) involves shaping polystyrene beads under heat and pressure into precise shapes, offering higher density and rigidity suited for applications like disposable cups, plates, and packaging inserts. Both EPS and MPS vary in density, structural integrity, and manufacturing process, affecting their thermal insulation, mechanical strength, and suitability for distinct industrial uses.

Manufacturing Processes Compared

Expanded polystyrene (EPS) is produced by expanding polystyrene beads using steam, allowing the material to form lightweight, rigid foam with a cellular structure ideal for insulation and packaging. Molded polystyrene (MPS) involves placing polystyrene beads into a mold, then heating and fusing them under pressure to create denser, more precise shapes used in food containers and disposable cups. The key manufacturing difference lies in EPS's steam expansion and partial fusion of beads versus MPS's fully molded and compressed bead fusion, impacting density, strength, and application.

Physical Properties and Structure

Expanded polystyrene (EPS) consists of pre-expanded beads fused together, resulting in a lightweight, rigid foam with a cellular structure that provides excellent thermal insulation and impact resistance. Molded polystyrene (MPS) is produced by injecting or compressing polystyrene beads into molds, forming denser, more uniform panels with enhanced rigidity, dimensional stability, and smoother surfaces. The physical properties of EPS emphasize low density and high energy absorption, while MPS offers higher mechanical strength and precise structural integrity for load-bearing applications.

Thermal Insulation Performance

Expanded polystyrene (EPS) offers superior thermal insulation performance due to its closed-cell structure with trapped air pockets that reduce heat transfer, making it ideal for building insulation and packaging. Molded polystyrene (MPS), produced under higher pressure and temperature, has a denser structure but generally lower insulating properties compared to EPS because of its reduced air content. The thermal resistance (R-value) of EPS typically ranges from 3.6 to 4.2 per inch, outperforming molded polystyrene in most insulation applications.

Mechanical Strength and Durability

Expanded polystyrene (EPS) exhibits lower mechanical strength compared to molded polystyrene (MPS) due to its bead-based structure, which results in less uniform density and higher fragility. Molded polystyrene provides superior durability and compressive strength, making it ideal for applications requiring higher load-bearing capacity and impact resistance. EPS is more prone to deformation under sustained stress, whereas MPS maintains structural integrity over prolonged use.

Common Applications of Each Type

Expanded polystyrene (EPS) is widely used in packaging, thermal insulation for buildings, and disposable food containers due to its lightweight and shock-absorbing properties. Molded polystyrene (MPS), on the other hand, is commonly employed in automotive parts, appliance housings, and custom packaging solutions requiring precise shapes and durability. The structural differences between EPS and MPS dictate their specialized applications across various industries.

Cost Analysis and Economic Considerations

Expanded polystyrene (EPS) typically offers lower production costs due to its simpler manufacturing process and lighter weight, making it more economically viable for bulk packaging and insulation applications. Molded polystyrene (MPS) incurs higher expenses stemming from its precise molding techniques and enhanced structural integrity, justifying its use in specialized or high-performance products. Cost analysis favors EPS for mass production needs, while MPS suits scenarios where durability and design complexity outweigh initial expenditure.

Environmental Impact and Recycling

Expanded polystyrene (EPS) has a lower density and is often used in packaging but poses significant challenges for recycling due to contamination and collection inefficiencies, leading to increased environmental pollution. Molded polystyrene (MPS), commonly used for food containers and insulation, tends to have more uniform composition, making it slightly easier to recycle, though both types contribute to long-term landfill accumulation because of their slow biodegradation rates. Innovations in recycling technologies and increased collection programs are crucial for minimizing the environmental impact and improving the sustainability of both EPS and MPS materials.

Customization and Design Flexibility

Expanded polystyrene (EPS) offers high customization and design flexibility through its ability to be easily molded into various shapes and sizes with differing densities, making it ideal for lightweight packaging and insulation applications. Molded polystyrene (MPS), produced via injection molding, provides superior precision and surface finish, allowing intricate and complex designs with tight tolerances, favored in automotive and consumer product components. The choice between EPS and MPS depends on specific requirements for design intricacy, customization depth, and functional performance in the intended application.

Choosing the Right Polystyrene for Your Needs

Expanded polystyrene (EPS) offers excellent insulation and impact resistance, making it ideal for packaging, construction, and insulation panels, while molded polystyrene (MPS) provides precise shapes and greater rigidity suited for protective packaging and detailed product casings. EPS is lightweight and cost-effective, allowing for versatile applications with good thermal performance, whereas molded polystyrene delivers higher strength and surface finish, essential for custom-fit protective solutions. Selecting between EPS and MPS depends on priorities like thermal insulation, structural strength, shaping complexity, and budget constraints specific to your project requirements.

Expanded polystyrene vs Molded polystyrene Infographic

materialdif.com

materialdif.com