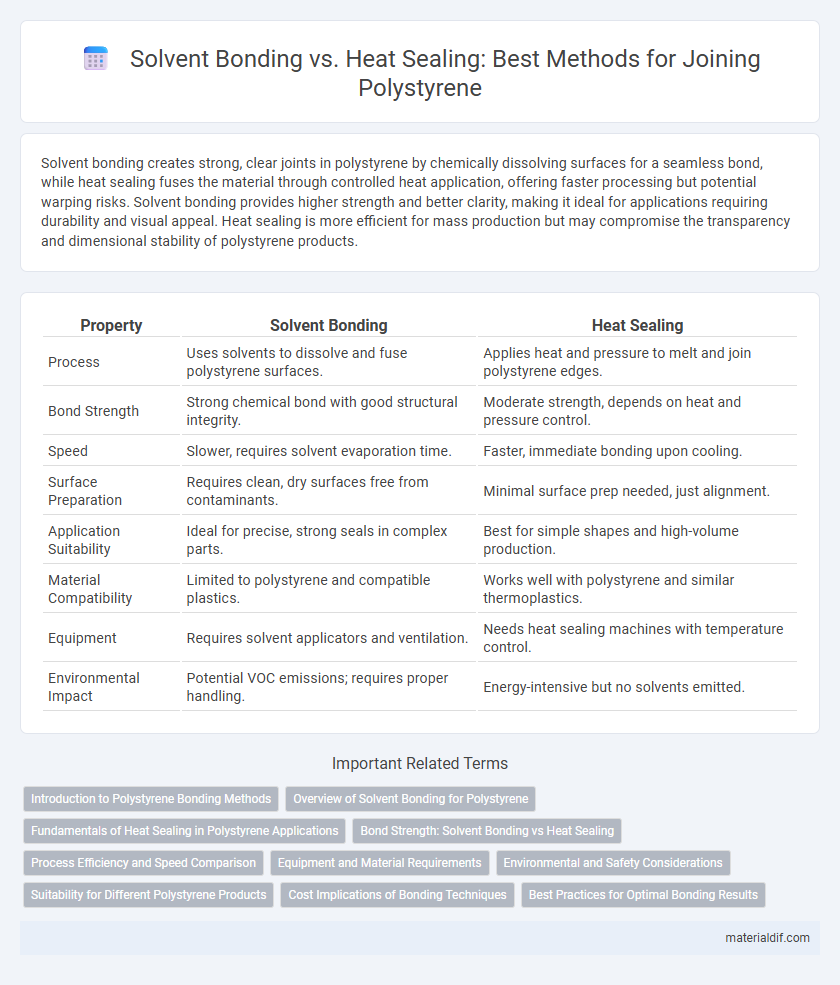

Solvent bonding creates strong, clear joints in polystyrene by chemically dissolving surfaces for a seamless bond, while heat sealing fuses the material through controlled heat application, offering faster processing but potential warping risks. Solvent bonding provides higher strength and better clarity, making it ideal for applications requiring durability and visual appeal. Heat sealing is more efficient for mass production but may compromise the transparency and dimensional stability of polystyrene products.

Table of Comparison

| Property | Solvent Bonding | Heat Sealing |

|---|---|---|

| Process | Uses solvents to dissolve and fuse polystyrene surfaces. | Applies heat and pressure to melt and join polystyrene edges. |

| Bond Strength | Strong chemical bond with good structural integrity. | Moderate strength, depends on heat and pressure control. |

| Speed | Slower, requires solvent evaporation time. | Faster, immediate bonding upon cooling. |

| Surface Preparation | Requires clean, dry surfaces free from contaminants. | Minimal surface prep needed, just alignment. |

| Application Suitability | Ideal for precise, strong seals in complex parts. | Best for simple shapes and high-volume production. |

| Material Compatibility | Limited to polystyrene and compatible plastics. | Works well with polystyrene and similar thermoplastics. |

| Equipment | Requires solvent applicators and ventilation. | Needs heat sealing machines with temperature control. |

| Environmental Impact | Potential VOC emissions; requires proper handling. | Energy-intensive but no solvents emitted. |

Introduction to Polystyrene Bonding Methods

Polystyrene bonding methods primarily include solvent bonding and heat sealing, each offering unique advantages based on application requirements. Solvent bonding chemically dissolves polystyrene surfaces, creating a strong, seamless joint ideal for intricate shapes and clear finishes, while heat sealing uses controlled thermal energy to fuse materials, providing rapid assembly and durability. Selecting the appropriate method depends on factors like product design, desired bond strength, and production speed in polystyrene manufacturing.

Overview of Solvent Bonding for Polystyrene

Solvent bonding for polystyrene involves using solvents such as acetone or MEK to dissolve the polymer surface, creating a molecular bond upon evaporation that results in a strong, clear joint. This method provides precise adhesion with minimal distortion, making it suitable for intricate designs and maintaining optical clarity. Compared to heat sealing, solvent bonding requires less energy and avoids thermal stress, preserving dimensional stability in polystyrene components.

Fundamentals of Heat Sealing in Polystyrene Applications

Heat sealing in polystyrene applications involves the localized application of heat and pressure to join polymer surfaces by melting the contact areas, enabling molecular diffusion and fusion upon cooling. This method offers precise control over seal strength and aesthetics, minimizing solvent exposure and preserving material clarity compared to solvent bonding, which relies on polymer dissolution and can compromise structural integrity. Effective heat sealing requires careful regulation of temperature, pressure, and dwell time tailored to polystyrene's thermal properties, typically sealing at temperatures near its glass transition point (~100degC to 120degC).

Bond Strength: Solvent Bonding vs Heat Sealing

Solvent bonding for polystyrene creates a chemically fused joint by dissolving and re-solidifying the polymer surface, resulting in higher bond strength and a more uniform seal compared to heat sealing. Heat sealing relies on melting the polymer's surface to join pieces, which can lead to weaker, less consistent bonds due to incomplete fusion or thermal degradation. Studies show solvent-bonded polystyrene joints typically exhibit superior tensile and shear strength, making them preferable for applications requiring robust, durable seals.

Process Efficiency and Speed Comparison

Solvent bonding of polystyrene offers faster curing times, typically within minutes, enhancing process efficiency for high-throughput production, whereas heat sealing requires longer cooling periods to achieve durable joints. The solvent bonding process allows precise application and strong chemical adhesion at lower temperatures, reducing energy consumption compared to the heat sealing method, which demands elevated temperatures and pressure. For rapid assembly and minimal thermal distortion, solvent bonding optimizes speed, while heat sealing provides robustness but at the cost of slower cycle times.

Equipment and Material Requirements

Solvent bonding of polystyrene requires specialized solvents such as acetone or toluene, along with precise application tools like brushes or spray systems to ensure strong adhesion without deforming the material. Heat sealing demands equipment capable of controlled temperature settings, such as hot plate welders or impulse sealers, to apply uniform heat and pressure that melts the polystyrene edges for a secure joint. Material requirements for solvent bonding include polystyrene forms compatible with the solvent chemicals, whereas heat sealing necessitates uniform thickness and purity to prevent uneven melting or warping during sealing.

Environmental and Safety Considerations

Solvent bonding for polystyrene involves the use of volatile organic compounds (VOCs) that pose inhalation risks and contribute to environmental pollution, requiring proper ventilation and handling protocols. Heat sealing eliminates chemical exposure by using controlled thermal energy to join surfaces but consumes significant energy and risks thermal degradation of the polymer. Balancing these methods involves assessing the trade-off between chemical safety hazards and energy consumption impacts on environmental sustainability.

Suitability for Different Polystyrene Products

Solvent bonding is ideal for lightweight polystyrene items such as packaging trays and disposable cups, where chemical adhesion provides a precise, clear bond without distorting the material. Heat sealing suits thicker or multilayer polystyrene products like rigid containers and protective cases, offering strong, durable seals capable of withstanding mechanical stress. The choice between solvent bonding and heat sealing depends on product thickness, desired bond strength, and clarity requirements for polystyrene applications.

Cost Implications of Bonding Techniques

Solvent bonding of polystyrene typically incurs lower initial equipment costs compared to heat sealing, which requires specialized thermal machinery and precise temperature control. The chemical-based bonding process allows for faster cycle times and reduced energy consumption, contributing to lower operational expenses. However, solvent bonding demands proper ventilation and handling of volatile organic compounds, potentially increasing safety-related costs and regulatory compliance expenses.

Best Practices for Optimal Bonding Results

Solvent bonding polystyrene requires using specific solvents like acetone or toluene that partially dissolve the polymer surface, enabling strong molecular fusion upon evaporation. Heat sealing demands precise temperature control between 190-230degC to avoid warping or incomplete bonds due to polystyrene's low melting point and thermal sensitivity. Best practices involve ensuring clean surfaces, applying uniform pressure, and conducting pre-bonding tests to determine optimal solvent dwell time or heating parameters for consistent, durable joints.

Solvent bonding vs Heat sealing (for polystyrene) Infographic

materialdif.com

materialdif.com