Expanded Polystyrene (EPS) is a lightweight, porous foam commonly used for packaging and insulation, offering excellent thermal performance with cost-effectiveness. Extruded Polystyrene (XPS) is denser and more moisture-resistant, making it ideal for applications requiring higher compressive strength and durability, such as insulation in foundations and roofs. Both types serve distinct purposes in construction and packaging, with EPS being preferred for its affordability and XPS for its enhanced structural properties.

Table of Comparison

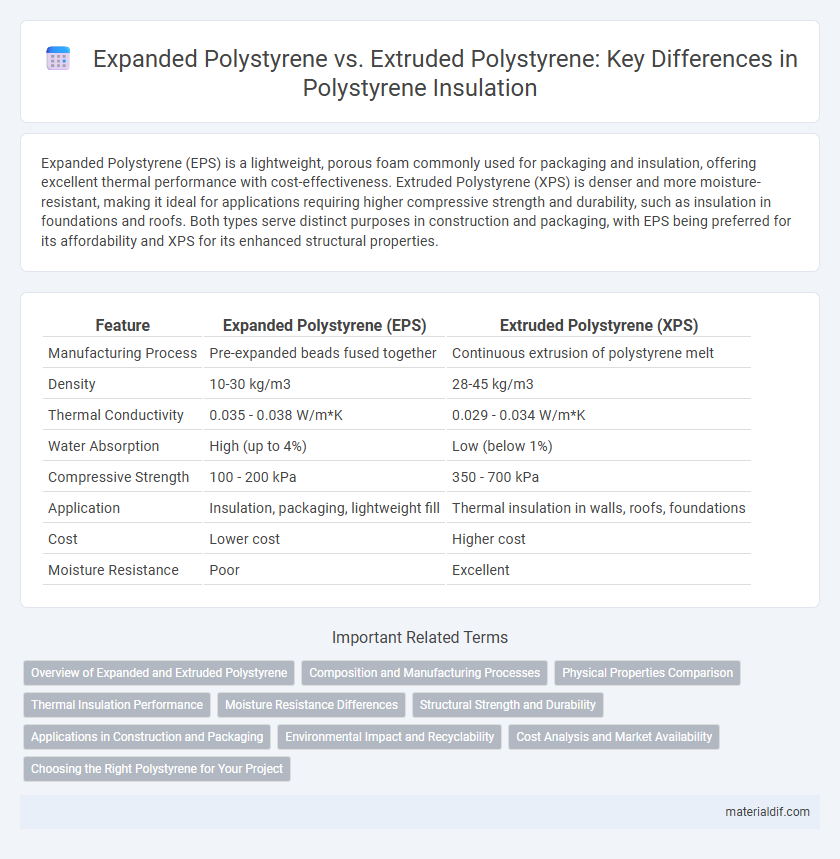

| Feature | Expanded Polystyrene (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Manufacturing Process | Pre-expanded beads fused together | Continuous extrusion of polystyrene melt |

| Density | 10-30 kg/m3 | 28-45 kg/m3 |

| Thermal Conductivity | 0.035 - 0.038 W/m*K | 0.029 - 0.034 W/m*K |

| Water Absorption | High (up to 4%) | Low (below 1%) |

| Compressive Strength | 100 - 200 kPa | 350 - 700 kPa |

| Application | Insulation, packaging, lightweight fill | Thermal insulation in walls, roofs, foundations |

| Cost | Lower cost | Higher cost |

| Moisture Resistance | Poor | Excellent |

Overview of Expanded and Extruded Polystyrene

Expanded Polystyrene (EPS) is a lightweight, rigid foam made from pre-expanded beads fused together, offering excellent insulation and cushioning properties in packaging and construction. Extruded Polystyrene (XPS) is produced through a continuous extrusion process, resulting in a denser, closed-cell foam with superior moisture resistance and compressive strength, commonly used for insulation in walls, roofs, and foundations. Both EPS and XPS provide effective thermal insulation, but EPS is more cost-effective and versatile for packaging, while XPS excels in durability and moisture resistance for structural applications.

Composition and Manufacturing Processes

Expanded Polystyrene (EPS) consists of pre-expanded polystyrene beads that are molded into shape using steam, creating a lightweight, porous structure with air-filled cells. Extruded Polystyrene (XPS) is produced by melting polystyrene crystals and forcing them through an extruder, forming a dense, closed-cell foam with uniform structure. The manufacturing process differences result in EPS having lower density and higher water absorption, while XPS offers superior compressive strength and moisture resistance.

Physical Properties Comparison

Expanded Polystyrene (EPS) features a bead-like structure with an open-cell composition, resulting in lower density ranging from 10 to 30 kg/m3 and moderate compressive strength typically between 70 to 170 kPa. Extruded Polystyrene (XPS) boasts a closed-cell structure, higher density from 28 to 45 kg/m3, and superior compressive strength often exceeding 350 kPa, making it more resistant to moisture and mechanical stress. Thermal conductivity values also differ, with EPS averaging around 0.038 W/m*K and XPS demonstrating lower thermal conductivity near 0.029 W/m*K, enhancing its insulation efficiency.

Thermal Insulation Performance

Expanded Polystyrene (EPS) features a bead structure with trapped air pockets that provide effective thermal insulation, typically exhibiting an R-value of 3.6 to 4.0 per inch. Extruded Polystyrene (XPS) has a closed-cell, uniform structure resulting in superior moisture resistance and a higher R-value ranging from 5.0 to 5.6 per inch, enhancing its thermal insulation performance. The denser composition of XPS makes it more efficient in minimizing heat transfer compared to EPS in thermal insulation applications.

Moisture Resistance Differences

Expanded Polystyrene (EPS) has a more open cell structure, making it less resistant to moisture absorption compared to Extruded Polystyrene (XPS), which features a closed-cell structure that significantly reduces water permeability. XPS typically exhibits a water absorption rate below 1%, providing superior moisture resistance in damp or wet environments. This makes XPS the preferred choice for applications requiring long-term exposure to moisture, such as foundation insulation and below-grade waterproofing.

Structural Strength and Durability

Expanded Polystyrene (EPS) features a lightweight, bead-like cellular structure that provides moderate compressive strength and is widely used for insulation and packaging, but it exhibits lower durability under long-term weather exposure. Extruded Polystyrene (XPS) is manufactured through an extrusion process, resulting in a denser, closed-cell structure with higher compressive strength and superior resistance to moisture, making it more suitable for load-bearing applications and environments requiring enhanced durability. The structural strength of XPS typically ranges from 20 to 40 psi, surpassing EPS, whose strength generally falls between 10 to 15 psi, reflecting XPS's advantage in durability and mechanical performance.

Applications in Construction and Packaging

Expanded Polystyrene (EPS) is widely used in construction for insulation, offering lightweight, thermal resistance, and moisture protection in walls, roofs, and foundations, while its cushioning properties make it ideal for packaging fragile goods. Extruded Polystyrene (XPS) provides higher compressive strength and water resistance, making it suitable for heavy-load applications such as below-grade insulation and rigid board insulation in commercial buildings. Both materials optimize energy efficiency and product protection, with EPS favored for packaging due to cost-effectiveness and XPS preferred in structural and moisture-intensive construction environments.

Environmental Impact and Recyclability

Expanded Polystyrene (EPS) features a lower density and is widely used in packaging and insulation, but it is less energy-intensive to produce and easier to recycle compared to Extruded Polystyrene (XPS). Extruded Polystyrene exhibits superior moisture resistance and insulation performance yet has a higher environmental impact due to its chemical blowing agents and more complex recycling processes. Both materials contribute to landfill waste, but EPS's open-cell structure allows for more efficient mechanical recycling and repurposing opportunities, reducing long-term environmental footprint.

Cost Analysis and Market Availability

Expanded Polystyrene (EPS) generally offers a lower cost per cubic foot compared to Extruded Polystyrene (XPS), making it a budget-friendly choice for insulation and packaging applications. XPS tends to have higher production costs due to its denser, more uniform structure, but it provides superior moisture resistance and compressive strength, justifying the premium in performance-critical markets. Market availability of EPS is widespread globally due to simpler manufacturing processes, while XPS is typically found in more specialized construction and industrial sectors with regional variations influenced by demand and production capacity.

Choosing the Right Polystyrene for Your Project

Expanded polystyrene (EPS) offers excellent thermal insulation and shock absorption at a lower cost, making it ideal for packaging and lightweight construction. Extruded polystyrene (XPS) provides higher compressive strength and moisture resistance, suitable for applications requiring durability and water protection, such as below-grade insulation. Selecting the right polystyrene depends on project requirements like load-bearing capacity, environmental exposure, and budget constraints.

Expanded Polystyrene vs Extruded Polystyrene Infographic

materialdif.com

materialdif.com