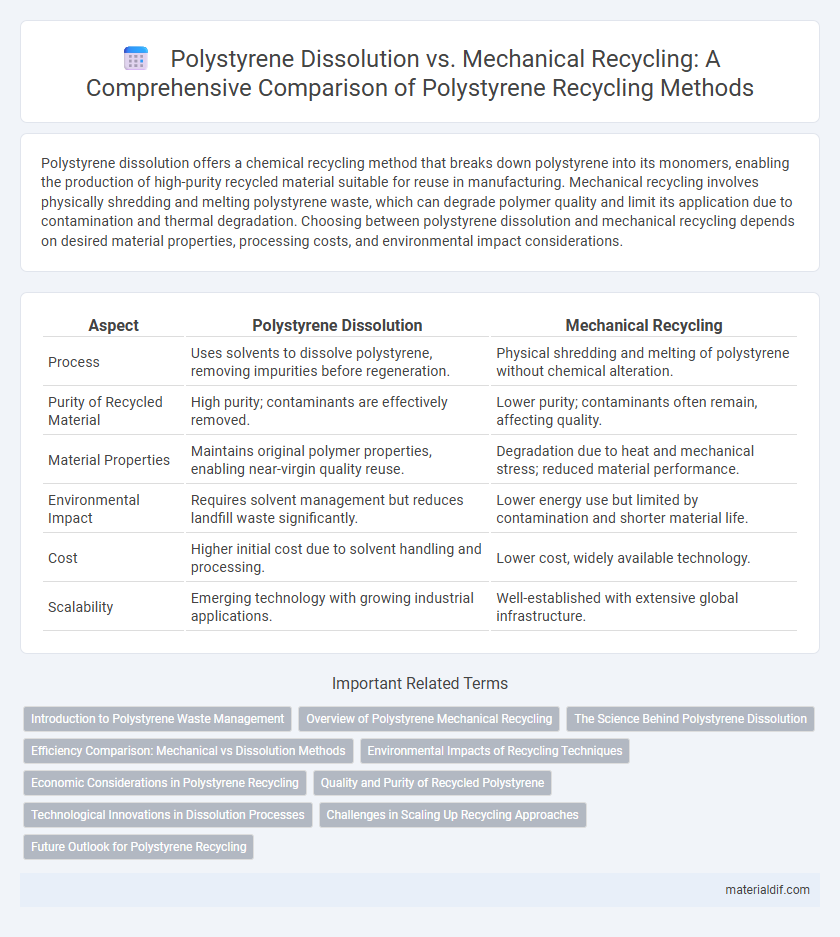

Polystyrene dissolution offers a chemical recycling method that breaks down polystyrene into its monomers, enabling the production of high-purity recycled material suitable for reuse in manufacturing. Mechanical recycling involves physically shredding and melting polystyrene waste, which can degrade polymer quality and limit its application due to contamination and thermal degradation. Choosing between polystyrene dissolution and mechanical recycling depends on desired material properties, processing costs, and environmental impact considerations.

Table of Comparison

| Aspect | Polystyrene Dissolution | Mechanical Recycling |

|---|---|---|

| Process | Uses solvents to dissolve polystyrene, removing impurities before regeneration. | Physical shredding and melting of polystyrene without chemical alteration. |

| Purity of Recycled Material | High purity; contaminants are effectively removed. | Lower purity; contaminants often remain, affecting quality. |

| Material Properties | Maintains original polymer properties, enabling near-virgin quality reuse. | Degradation due to heat and mechanical stress; reduced material performance. |

| Environmental Impact | Requires solvent management but reduces landfill waste significantly. | Lower energy use but limited by contamination and shorter material life. |

| Cost | Higher initial cost due to solvent handling and processing. | Lower cost, widely available technology. |

| Scalability | Emerging technology with growing industrial applications. | Well-established with extensive global infrastructure. |

Introduction to Polystyrene Waste Management

Polystyrene waste management involves two primary methods: dissolution and mechanical recycling, each with distinct environmental and operational impacts. Dissolution effectively recovers polystyrene by dissolving the material in solvents, enabling the removal of contaminants and yielding high-purity recycled polystyrene suitable for sensitive applications. Mechanical recycling, in contrast, processes polystyrene waste through physical means like shredding and melting, offering a cost-effective but often lower-quality recycled product due to material degradation during reuse.

Overview of Polystyrene Mechanical Recycling

Polystyrene mechanical recycling involves the collection, sorting, and reprocessing of PS waste into reusable pellets through shredding and melting without altering its chemical structure. This method preserves the polymer's intrinsic properties, enabling the production of new items such as packaging materials, insulation panels, and disposable cutlery. Compared to dissolution recycling, mechanical recycling offers lower energy consumption and cost-effectiveness but may suffer from material degradation over multiple cycles.

The Science Behind Polystyrene Dissolution

Polystyrene dissolution involves breaking down the polymer chains in solvents such as limonene or acetone, enabling the recovery of pure polystyrene for reuse without degrading its molecular weight. This chemical process contrasts with mechanical recycling, where polystyrene is melted and remolded, often resulting in polymer chain scission and reduced material properties. Understanding solvent-polymer interactions at the molecular level highlights how dissolution preserves polymer integrity, leading to higher quality recycled products compared to traditional mechanical methods.

Efficiency Comparison: Mechanical vs Dissolution Methods

Polystyrene dissolution offers higher purity recovery by selectively dissolving the polymer, reducing contamination and maintaining polymer integrity compared to mechanical recycling, which often results in degraded material quality due to thermal and mechanical stress. Mechanical recycling of polystyrene is more energy-efficient and cost-effective but suffers from polymer chain scission, leading to lower tensile strength and reduced material performance in reused products. Efficiency comparison indicates that dissolution methods achieve superior polymer recovery rates above 90%, while mechanical recycling typically recovers around 70-80% of usable material with diminished mechanical properties.

Environmental Impacts of Recycling Techniques

Polystyrene dissolution recycling reduces environmental impacts by enabling the recovery of high-purity polymer with minimal degradation, resulting in lower energy consumption compared to mechanical recycling. Mechanical recycling of polystyrene often leads to polymer chain degradation, decreasing material quality and limiting reuse potential, which generates more plastic waste and higher greenhouse gas emissions over time. Solvent-based dissolution processes also decrease microplastic release and mitigate contamination, offering a more sustainable alternative to traditional mechanical recycling methods.

Economic Considerations in Polystyrene Recycling

Polystyrene dissolution offers higher purity recovery but involves greater solvent and energy costs compared to mechanical recycling, which is more cost-effective with lower operational expenses but yields lower-quality material. Economic feasibility depends on market demand, scale of operation, and price volatility of recycled resins and solvents. Optimizing cost-benefit ratios requires balancing recovery efficiency with processing expenditures to maximize profitability in polystyrene recycling.

Quality and Purity of Recycled Polystyrene

Polystyrene dissolution achieves higher purity and quality in recycled material by selectively dissolving and separating contaminants, resulting in fewer impurities and better structural integrity compared to mechanical recycling. Mechanical recycling often leads to degraded polymer chains and mixed contamination, reducing the final product's performance and limiting its reuse applications. Advanced solvent-based dissolution techniques enable the recovery of near-virgin quality polystyrene suitable for high-value applications.

Technological Innovations in Dissolution Processes

Recent technological innovations in polystyrene dissolution focus on advanced solvent selection and process optimization to enhance polymer recovery efficiency. Enhanced dissolution techniques enable selective separation of contaminants, preserving polymer integrity for higher-quality recycled material. These innovations reduce environmental impact by minimizing energy consumption and solvent waste compared to traditional mechanical recycling methods.

Challenges in Scaling Up Recycling Approaches

Polystyrene dissolution faces significant challenges in scaling up due to the need for large volumes of solvents, extended processing times, and solvent recovery systems that increase operational costs. Mechanical recycling of polystyrene is limited by the material's low melt strength and contamination sensitivity, which result in downgraded mechanical properties and reduced recyclate quality at industrial scales. Both approaches struggle with inconsistent feedstock quality and economic feasibility that hinder widespread adoption in commercial recycling operations.

Future Outlook for Polystyrene Recycling

Advancements in polystyrene dissolution techniques offer promising opportunities for improving recycling efficiency by enabling the recovery of high-purity polymer suitable for reuse in manufacturing. Mechanical recycling, while currently more widespread, faces challenges such as polymer degradation and contamination that limit the quality of recycled material. Future developments are expected to integrate chemical dissolution methods with automated sorting technologies, enhancing the circular economy potential for polystyrene and reducing environmental impact.

Polystyrene Dissolution vs Mechanical Recycling Infographic

materialdif.com

materialdif.com