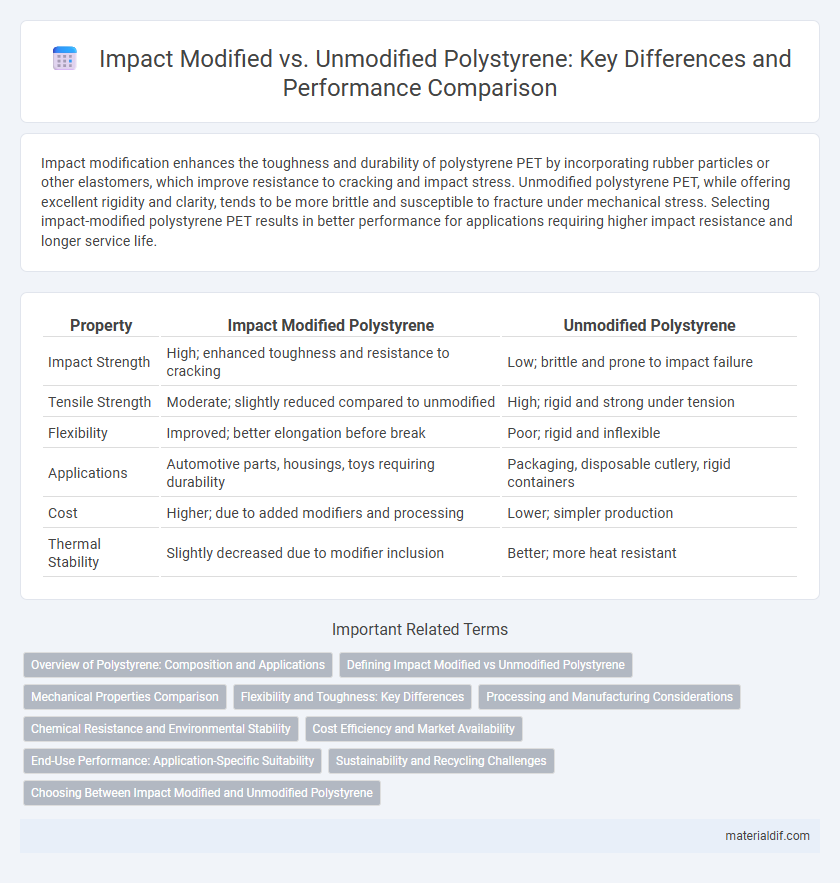

Impact modification enhances the toughness and durability of polystyrene PET by incorporating rubber particles or other elastomers, which improve resistance to cracking and impact stress. Unmodified polystyrene PET, while offering excellent rigidity and clarity, tends to be more brittle and susceptible to fracture under mechanical stress. Selecting impact-modified polystyrene PET results in better performance for applications requiring higher impact resistance and longer service life.

Table of Comparison

| Property | Impact Modified Polystyrene | Unmodified Polystyrene |

|---|---|---|

| Impact Strength | High; enhanced toughness and resistance to cracking | Low; brittle and prone to impact failure |

| Tensile Strength | Moderate; slightly reduced compared to unmodified | High; rigid and strong under tension |

| Flexibility | Improved; better elongation before break | Poor; rigid and inflexible |

| Applications | Automotive parts, housings, toys requiring durability | Packaging, disposable cutlery, rigid containers |

| Cost | Higher; due to added modifiers and processing | Lower; simpler production |

| Thermal Stability | Slightly decreased due to modifier inclusion | Better; more heat resistant |

Overview of Polystyrene: Composition and Applications

Polystyrene is a synthetic aromatic polymer made from the monomer styrene, widely used in packaging, insulation, and disposable consumer products due to its rigidity and clarity. Impact-modified polystyrene (HIPS) incorporates rubber additives, enhancing toughness and resistance to impact without sacrificing processability, making it suitable for automotive parts and protective packaging. Unmodified polystyrene, by contrast, remains brittle and is primarily used where rigidity and low cost are more critical than impact resistance.

Defining Impact Modified vs Unmodified Polystyrene

Impact modified polystyrene contains rubber or elastomeric additives that enhance its toughness and resistance to impact, making it suitable for applications requiring increased durability. Unmodified polystyrene, also known as general-purpose polystyrene, is rigid and brittle, offering excellent clarity but limited impact strength. The key distinction lies in the molecular structure alterations that improve energy absorption in impact modified grades compared to the brittle nature of unmodified polystyrene.

Mechanical Properties Comparison

Impact-modified polystyrene exhibits significantly enhanced toughness and impact resistance compared to unmodified polystyrene, which tends to be brittle and prone to cracking under stress. The incorporation of rubber or elastomeric additives in impact-modified grades improves elongation at break and energy absorption during impact, making it suitable for applications requiring durability. Unmodified polystyrene, while maintaining higher stiffness and rigidity, offers lower impact strength and reduced mechanical shock resistance.

Flexibility and Toughness: Key Differences

Impact-modified polystyrene (IMS) exhibits significantly enhanced flexibility and toughness compared to unmodified polystyrene due to the incorporation of rubber particles, which absorb and dissipate energy during impact. Unmodified polystyrene is inherently rigid and brittle, making it prone to cracking under stress, whereas IMS maintains structural integrity under similar conditions. These differences make impact-modified polystyrene ideal for applications requiring improved shock resistance and durability.

Processing and Manufacturing Considerations

Impact modified polystyrene (IMS) offers enhanced toughness and resistance to cracking during processing compared to unmodified polystyrene, reducing defect rates in injection molding and extrusion applications. IMS requires optimized processing temperatures, typically between 200-250degC, to achieve proper melt flow and maintain impact modifiers' dispersion. Unmodified polystyrene, with its higher stiffness but brittleness, processes at slightly lower temperatures around 180-230degC, necessitating careful control to avoid thermal degradation and brittle fracture during manufacturing.

Chemical Resistance and Environmental Stability

Impact-modified polystyrene contains elastomeric additives that enhance its toughness but generally reduce chemical resistance compared to unmodified polystyrene, which offers better barrier properties against solvents and acids. Environmental stability in impact-modified polystyrene is often compromised due to the added rubber phase, making it more susceptible to UV degradation and weathering. Conversely, unmodified polystyrene exhibits superior environmental resistance, maintaining structural integrity in outdoor applications with minimal degradation over time.

Cost Efficiency and Market Availability

Impact modified polystyrene (IMPS) offers enhanced toughness and durability compared to unmodified polystyrene, making it suitable for applications requiring higher impact resistance despite a slightly higher production cost. Unmodified polystyrene remains more cost-efficient due to simpler manufacturing processes and wider market availability, which benefits industries focusing on low-cost, lightweight products. Market demand and production scale heavily favor unmodified polystyrene, but impact modified variants continue to grow in sectors requiring improved mechanical properties.

End-Use Performance: Application-Specific Suitability

Impact-modified polystyrene exhibits enhanced toughness and resistance to cracking, making it ideal for applications requiring durability, such as automotive parts and appliances. Unmodified polystyrene delivers higher rigidity and clarity, suited for packaging and disposable cutlery where stiffness and transparency are crucial. Selecting between these materials depends on the balance of mechanical strength and aesthetic requirements demanded by the end-use application.

Sustainability and Recycling Challenges

Impact-modified polystyrene contains rubber additives that improve toughness but complicate recycling due to heterogeneous material composition, leading to lower recyclate quality compared to unmodified polystyrene. Unmodified polystyrene is more straightforward to recycle since it comprises a single polymer type, facilitating better material recovery and remanufacturing processes. Sustainability efforts prioritize unmodified polystyrene for circular economy applications, while impact-modified variants require advanced separation technologies to enhance recycling efficiency.

Choosing Between Impact Modified and Unmodified Polystyrene

Impact modified polystyrene (IMS) offers enhanced toughness and resistance to impact, making it ideal for applications requiring durability and shock absorption, such as automotive parts and protective casings. Unmodified polystyrene provides superior rigidity and clarity, often preferred for packaging and disposable consumer goods where cost-efficiency and aesthetics are critical. Selecting between IMS and unmodified polystyrene depends on balancing mechanical performance requirements with budget constraints and the intended application environment.

Impact Modification vs Unmodified Polystyrene Infographic

materialdif.com

materialdif.com