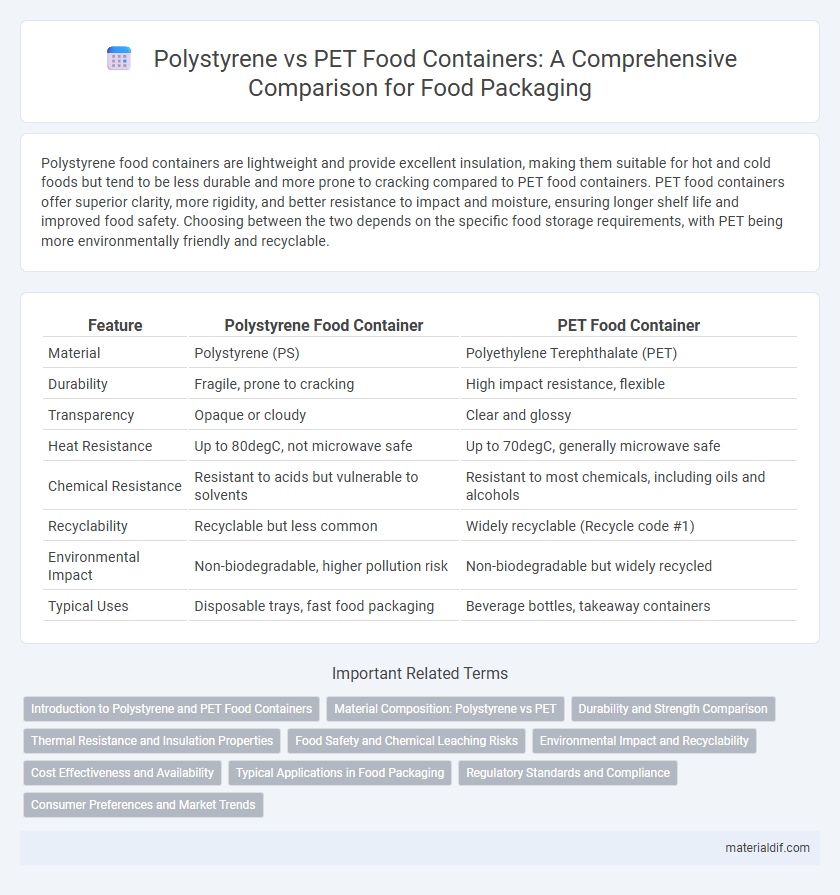

Polystyrene food containers are lightweight and provide excellent insulation, making them suitable for hot and cold foods but tend to be less durable and more prone to cracking compared to PET food containers. PET food containers offer superior clarity, more rigidity, and better resistance to impact and moisture, ensuring longer shelf life and improved food safety. Choosing between the two depends on the specific food storage requirements, with PET being more environmentally friendly and recyclable.

Table of Comparison

| Feature | Polystyrene Food Container | PET Food Container |

|---|---|---|

| Material | Polystyrene (PS) | Polyethylene Terephthalate (PET) |

| Durability | Fragile, prone to cracking | High impact resistance, flexible |

| Transparency | Opaque or cloudy | Clear and glossy |

| Heat Resistance | Up to 80degC, not microwave safe | Up to 70degC, generally microwave safe |

| Chemical Resistance | Resistant to acids but vulnerable to solvents | Resistant to most chemicals, including oils and alcohols |

| Recyclability | Recyclable but less common | Widely recyclable (Recycle code #1) |

| Environmental Impact | Non-biodegradable, higher pollution risk | Non-biodegradable but widely recycled |

| Typical Uses | Disposable trays, fast food packaging | Beverage bottles, takeaway containers |

Introduction to Polystyrene and PET Food Containers

Polystyrene food containers, made from a lightweight, rigid plastic polymer, offer excellent insulation and cost-effectiveness for single-use packaging applications. PET (polyethylene terephthalate) food containers, known for their clarity, durability, and recyclability, provide superior moisture resistance and strength compared to polystyrene. Both materials serve distinct purposes in the food packaging industry, balancing factors like thermal resistance, environmental impact, and product protection.

Material Composition: Polystyrene vs PET

Polystyrene food containers are made from a synthetic aromatic hydrocarbon polymer derived from the monomer styrene, known for its rigidity, thermal insulation, and clarity. PET (Polyethylene Terephthalate) food containers are composed of a thermoplastic polyester derived from the polymerization of ethylene glycol and terephthalic acid, valued for its strength, transparency, and recyclability. The molecular structure differences result in polystyrene being more brittle and less resistant to heat, while PET offers greater durability and chemical resistance, making it preferable for various food packaging applications.

Durability and Strength Comparison

Polystyrene food containers exhibit moderate durability but tend to become brittle at low temperatures and can crack under stress, limiting their long-term strength. PET food containers offer superior durability and impact resistance, maintaining structural integrity under varied temperature conditions and rough handling. The strength of PET containers makes them more suitable for repeated use and transportation compared to polystyrene counterparts.

Thermal Resistance and Insulation Properties

Polystyrene food containers offer excellent thermal resistance due to their low thermal conductivity, making them effective in maintaining food temperature for extended periods. PET food containers provide moderate insulation but tend to lose heat faster than polystyrene, reducing their effectiveness for hot food storage. The superior insulation properties of polystyrene make it the preferred choice for applications requiring heat retention and durability under thermal stress.

Food Safety and Chemical Leaching Risks

Polystyrene food containers pose higher food safety and chemical leaching risks compared to PET containers due to the potential release of styrene, a possible carcinogen, especially when exposed to heat or fatty foods. PET containers are considered safer for food contact as they exhibit minimal chemical migration and have been extensively tested to meet FDA and EFSA standards for food-grade materials. Choosing PET over polystyrene reduces exposure to harmful compounds and improves overall food safety in packaging applications.

Environmental Impact and Recyclability

Polystyrene food containers are lightweight and insulative but contribute significantly to environmental pollution due to their slow degradation and limited recyclability, often ending up in landfills or oceans. PET food containers, made from polyethylene terephthalate, are more widely recycled through established systems, reducing landfill waste and environmental harm. The chemical structure of PET allows for effective recycling into new containers, making it a more sustainable choice compared to polystyrene.

Cost Effectiveness and Availability

Polystyrene food containers are generally more cost-effective than PET containers, offering a lower price point suitable for large-scale food packaging. Availability of polystyrene containers is widespread due to their simple manufacturing process and extensive global production. PET containers, while more expensive, tend to be preferred for their durability and recyclability, though their availability can be limited depending on regional recycling capabilities and manufacturing infrastructure.

Typical Applications in Food Packaging

Polystyrene food containers are commonly used for takeout meals, deli trays, and egg cartons due to their excellent insulation properties and rigidity, making them ideal for hot and cold food items. PET food containers are preferred for fresh produce, salads, and beverages because of their superior clarity, durability, and resistance to moisture, ensuring product freshness and visibility. Both materials fulfill specific packaging needs, with polystyrene excelling in insulation and PET in transparency and strength for diverse food applications.

Regulatory Standards and Compliance

Polystyrene food containers must adhere to FDA regulations under 21 CFR 177.1640, ensuring safe use with food by limiting styrene monomer migration. PET food containers comply with FDA 21 CFR 177.1630 standards, focusing on restrictions related to glycol copolymers and overall migratory limits to guarantee food safety. Both materials require compliance with FDA migration testing protocols and local regulatory bodies such as the European Food Safety Authority (EFSA) for global market approval.

Consumer Preferences and Market Trends

Polystyrene food containers are favored for their lightweight and insulating properties, making them popular in fast food and takeout markets, while PET containers are preferred for their clarity, durability, and recyclability, gaining traction among environmentally conscious consumers. Market trends indicate a rising demand for PET containers due to increasing regulations and consumer awareness of sustainability, pushing manufacturers to adopt eco-friendly packaging solutions. Consumer preferences shift towards PET for its perceived safety and eco-friendliness, although polystyrene remains competitive due to lower cost and superior thermal insulation.

Polystyrene Food Container vs PET Food Container Infographic

materialdif.com

materialdif.com