Rigid polystyrene is characterized by its high strength, clarity, and structural integrity, making it ideal for applications such as packaging, disposable cutlery, and CD cases. Flexible polystyrene, on the other hand, offers elasticity and durability, commonly used in items like toys, insulation panels, and certain medical devices. Understanding the differences in durability, flexibility, and application suitability is crucial for choosing between rigid and flexible polystyrene in product design.

Table of Comparison

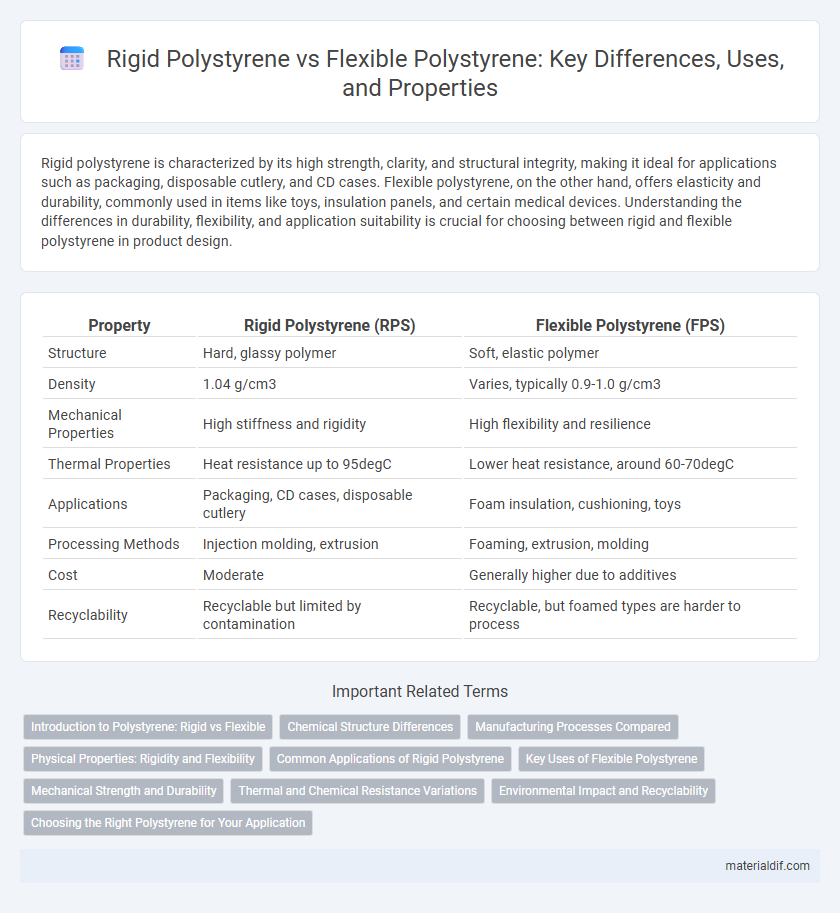

| Property | Rigid Polystyrene (RPS) | Flexible Polystyrene (FPS) |

|---|---|---|

| Structure | Hard, glassy polymer | Soft, elastic polymer |

| Density | 1.04 g/cm3 | Varies, typically 0.9-1.0 g/cm3 |

| Mechanical Properties | High stiffness and rigidity | High flexibility and resilience |

| Thermal Properties | Heat resistance up to 95degC | Lower heat resistance, around 60-70degC |

| Applications | Packaging, CD cases, disposable cutlery | Foam insulation, cushioning, toys |

| Processing Methods | Injection molding, extrusion | Foaming, extrusion, molding |

| Cost | Moderate | Generally higher due to additives |

| Recyclability | Recyclable but limited by contamination | Recyclable, but foamed types are harder to process |

Introduction to Polystyrene: Rigid vs Flexible

Rigid polystyrene exhibits high tensile strength and structural integrity, making it ideal for applications such as plastic containers and rigid foam insulation. Flexible polystyrene, characterized by its elastic properties and softness, is commonly used in packaging foams and cushioning materials. The distinct molecular arrangements and additives differentiate their mechanical behaviors, influencing their suitability across diverse industrial uses.

Chemical Structure Differences

Rigid polystyrene consists of a tightly packed, highly cross-linked polymer chain structure that results in a hard, brittle material with high dimensional stability. Flexible polystyrene incorporates plasticizers or copolymers that interrupt the polystyrene backbone, reducing intermolecular forces and increasing elasticity and impact resistance. These chemical structure modifications directly influence the mechanical properties, making rigid polystyrene suitable for structural applications while flexible polystyrene is used in cushioning and insulation.

Manufacturing Processes Compared

Rigid polystyrene (RPS) is typically produced through bulk or mass polymerization, resulting in a dense, high-strength material used in applications like insulation and packaging, while flexible polystyrene (FPS) is manufactured via suspension polymerization combined with the incorporation of plasticizers or rubber modifiers to enhance elasticity for products such as foam cushioning and insulation boards. The manufacturing process for RPS involves controlled temperature and mixing to achieve a crystalline structure, whereas FPS production requires precise control of polymer particle size and the addition of softening agents to attain flexibility. These differences in polymerization techniques and additive use directly impact the mechanical properties and end-use applications of each polystyrene variant.

Physical Properties: Rigidity and Flexibility

Rigid polystyrene exhibits high rigidity, making it ideal for applications requiring structural stability and impact resistance, such as in disposable cutlery and CD cases. Flexible polystyrene incorporates plasticizers, enhancing its flexibility and enabling use in products like insulation sheets and cushioning materials. The inherent difference in molecular structure and additives directly influences their mechanical properties, dictating suitability across various industrial applications.

Common Applications of Rigid Polystyrene

Rigid polystyrene is widely used in applications requiring structural strength and dimensional stability, such as in disposable cutlery, CD cases, and model building materials. Its clarity and rigidity make it suitable for packaging products, including food containers and protective casings. The material's ease of molding and resistance to impact contribute to its popularity in manufacturing rigid components for household appliances and office equipment.

Key Uses of Flexible Polystyrene

Flexible polystyrene is primarily used in applications requiring cushioning and shock absorption, such as upholstery foam, automotive seating, and packaging materials that protect delicate items during shipping. Its elasticity and resilience make it ideal for creating flexible foam blocks, mattress padding, and carpet underlayments. Unlike rigid polystyrene, flexible polystyrene excels in comfort-oriented and protective functions due to its capacity to compress and recover.

Mechanical Strength and Durability

Rigid polystyrene exhibits high mechanical strength and superior durability, making it ideal for applications requiring structural integrity and long-term performance. Flexible polystyrene, while less robust, offers enhanced elasticity and impact resistance, suitable for cushioning and insulation purposes. The difference in molecular structure and polymerization processes directly influences their mechanical properties and service life.

Thermal and Chemical Resistance Variations

Rigid polystyrene exhibits higher thermal resistance with a glass transition temperature around 100degC, making it suitable for applications requiring structural stability under heat. Flexible polystyrene, modified with elastomers, offers lower thermal resistance but improved impact strength and chemical resistance to solvents and oils. Variations in polymer morphology account for these differences, influencing their performance in thermal insulation and chemical exposure environments.

Environmental Impact and Recyclability

Rigid polystyrene (RPS) is more commonly recycled due to its higher density and uniform structure, which facilitates sorting and processing in recycling facilities. Flexible polystyrene (FPS), often used in packaging foams, poses greater environmental challenges because of its low density, large volume, and contamination issues, leading to limited recyclability and higher landfill accumulation. Both types contribute to environmental pollution, but advancements in recycling technologies and increased collection infrastructure are improving the recovery rates of RPS more significantly than FPS.

Choosing the Right Polystyrene for Your Application

Rigid polystyrene offers high strength and dimensional stability, making it ideal for applications requiring structural integrity such as packaging and model making. Flexible polystyrene provides enhanced elasticity and impact resistance, which suits products like insulation, cushioning, and protective packaging. Selecting the right polystyrene depends on balancing mechanical properties with the specific demands of thermal insulation, flexibility, and durability in your application.

Rigid Polystyrene vs Flexible Polystyrene Infographic

materialdif.com

materialdif.com