Biodegradable options for polystyrene PET offer significant environmental advantages by breaking down naturally and reducing landfill accumulation, unlike conventional polystyrene which persists for centuries. These eco-friendly alternatives are typically made from renewable resources, enhancing sustainability without compromising material strength or durability. Transitioning to biodegradable polystyrene PET helps mitigate pollution and supports circular economy initiatives in packaging industries.

Table of Comparison

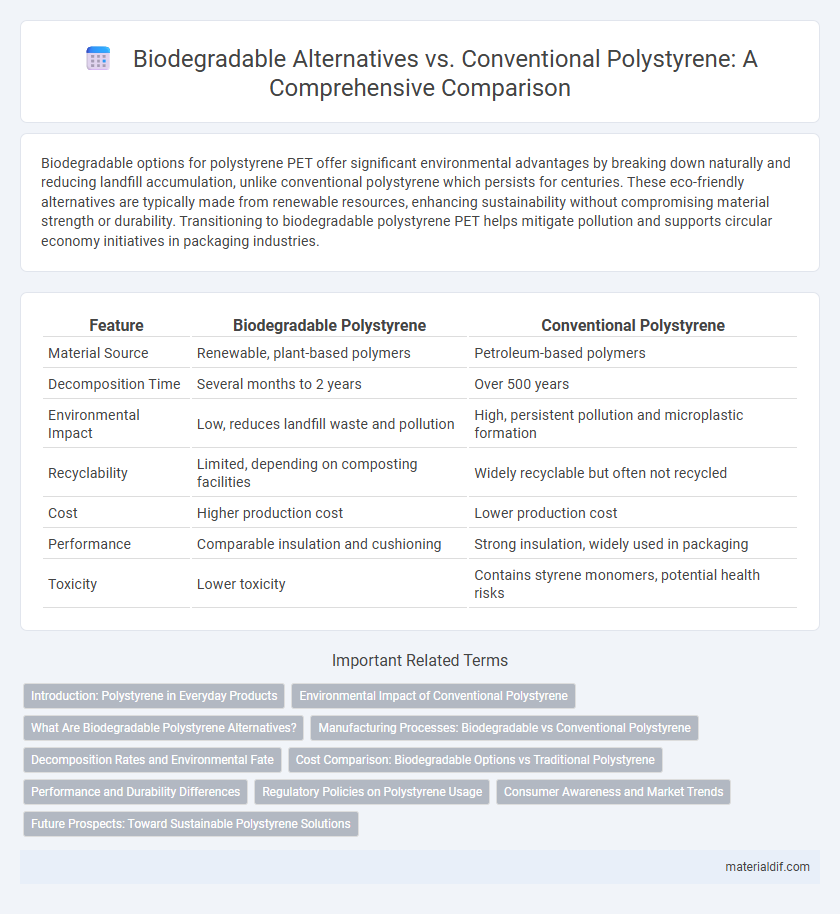

| Feature | Biodegradable Polystyrene | Conventional Polystyrene |

|---|---|---|

| Material Source | Renewable, plant-based polymers | Petroleum-based polymers |

| Decomposition Time | Several months to 2 years | Over 500 years |

| Environmental Impact | Low, reduces landfill waste and pollution | High, persistent pollution and microplastic formation |

| Recyclability | Limited, depending on composting facilities | Widely recyclable but often not recycled |

| Cost | Higher production cost | Lower production cost |

| Performance | Comparable insulation and cushioning | Strong insulation, widely used in packaging |

| Toxicity | Lower toxicity | Contains styrene monomers, potential health risks |

Introduction: Polystyrene in Everyday Products

Polystyrene is widely used in everyday products such as packaging, disposable cutlery, and insulation due to its lightweight and durable properties. Conventional polystyrene, derived from petroleum, poses significant environmental challenges because it is non-biodegradable and contributes to long-lasting pollution in landfills and oceans. Biodegradable alternatives, made from natural polymers like polylactic acid (PLA) or starch-based materials, offer eco-friendly options that break down faster and reduce environmental impact.

Environmental Impact of Conventional Polystyrene

Conventional polystyrene poses significant environmental challenges due to its non-biodegradability and persistence in ecosystems, contributing to long-term pollution in landfills and oceans. Its production relies heavily on fossil fuels, resulting in substantial carbon emissions and resource depletion. Compared to biodegradable alternatives, conventional polystyrene lacks effective decomposition pathways, leading to harmful microplastic accumulation and adverse effects on marine and terrestrial wildlife.

What Are Biodegradable Polystyrene Alternatives?

Biodegradable polystyrene alternatives include materials such as polylactic acid (PLA), starch-based polymers, and polyhydroxyalkanoates (PHA), which decompose naturally through microbial action. These alternatives reduce environmental impact by breaking down more efficiently in composting conditions compared to conventional polystyrene, which can persist for hundreds of years in landfills. Innovations in biodegradable blends and additives aim to mimic the functional properties of traditional polystyrene while promoting sustainability and reducing plastic pollution.

Manufacturing Processes: Biodegradable vs Conventional Polystyrene

Manufacturing biodegradable polystyrene involves the use of bio-based materials such as polylactic acid (PLA) or starch blends, which undergo fermentation or enzymatic treatment to create compostable polymers, contrasting with the petroleum-derived monomers polymerized through free-radical processes in conventional polystyrene production. Biodegradable alternatives require careful control of moisture and temperature during processing to maintain polymer integrity and enhance biodegradability, while conventional polystyrene relies on high-temperature, energy-intensive polymerization techniques with catalysts like benzoyl peroxide or AIBN. The production of biodegradable polystyrene integrates sustainable feedstocks and eco-friendly solvents, reducing carbon footprint and waste generation compared to the extensive fossil fuel usage and environmental persistence associated with traditional polystyrene manufacturing.

Decomposition Rates and Environmental Fate

Biodegradable polystyrene alternatives exhibit significantly faster decomposition rates, breaking down within months to a few years under industrial composting conditions, compared to conventional polystyrene which can persist in the environment for hundreds of years. Conventional polystyrene tends to fragment into microplastics, contributing to long-term soil and marine pollution, whereas biodegradable options minimize environmental accumulation by converting into biomass, carbon dioxide, and water. Understanding these differences is crucial for reducing plastic pollution and mitigating the ecological impact of polystyrene waste.

Cost Comparison: Biodegradable Options vs Traditional Polystyrene

Biodegradable options for polystyrene, such as polylactic acid (PLA) or starch-based foams, generally incur higher production and raw material costs compared to conventional polystyrene derived from petroleum. These increased expenses result in price premiums that may be two to three times greater than traditional polystyrene products, impacting large-scale industrial adoption. However, the long-term environmental savings and potential regulatory incentives can offset upfront costs over time, influencing overall economic viability.

Performance and Durability Differences

Biodegradable polystyrene alternatives often exhibit reduced mechanical strength and shorter lifespan compared to conventional polystyrene, impacting their suitability for long-term or heavy-duty applications. Conventional polystyrene provides superior thermal insulation, moisture resistance, and structural integrity, making it more durable in packaging and construction uses. Performance trade-offs include faster degradation rates for biodegradable options, resulting in decreased durability but improved environmental impact.

Regulatory Policies on Polystyrene Usage

Regulatory policies on polystyrene usage increasingly favor biodegradable alternatives due to their reduced environmental impact and enhanced compostability. Governments worldwide implement bans or restrictions on conventional polystyrene foam products, promoting the adoption of biodegradable polymers such as polylactic acid (PLA) and starch-based materials. These regulations aim to reduce plastic pollution and encourage innovation in sustainable packaging solutions.

Consumer Awareness and Market Trends

Consumer awareness of biodegradable options is steadily increasing as environmental concerns push demand for sustainable alternatives to conventional polystyrene, which is known for its persistence and pollution issues. Market trends indicate a growing preference for eco-friendly packaging materials like polylactic acid (PLA) and starch-based foams, driven by stricter regulations and corporate sustainability commitments. Despite higher costs, biodegradable polystyrene alternatives are gaining traction among environmentally conscious consumers and businesses seeking to reduce plastic waste impact.

Future Prospects: Toward Sustainable Polystyrene Solutions

Biodegradable alternatives to conventional polystyrene, such as polylactic acid (PLA) and starch-based foams, offer promising pathways to reduce environmental impact through enhanced degradation rates and compostability. Innovations in polymer chemistry aim to maintain the functional properties of traditional polystyrene while integrating biodegradable monomers and additives to create eco-friendly composites. Future prospects emphasize advancing recycling technologies and bio-based feedstocks to establish a circular economy model for sustainable polystyrene production and waste management.

Biodegradable options vs Conventional Polystyrene Infographic

materialdif.com

materialdif.com