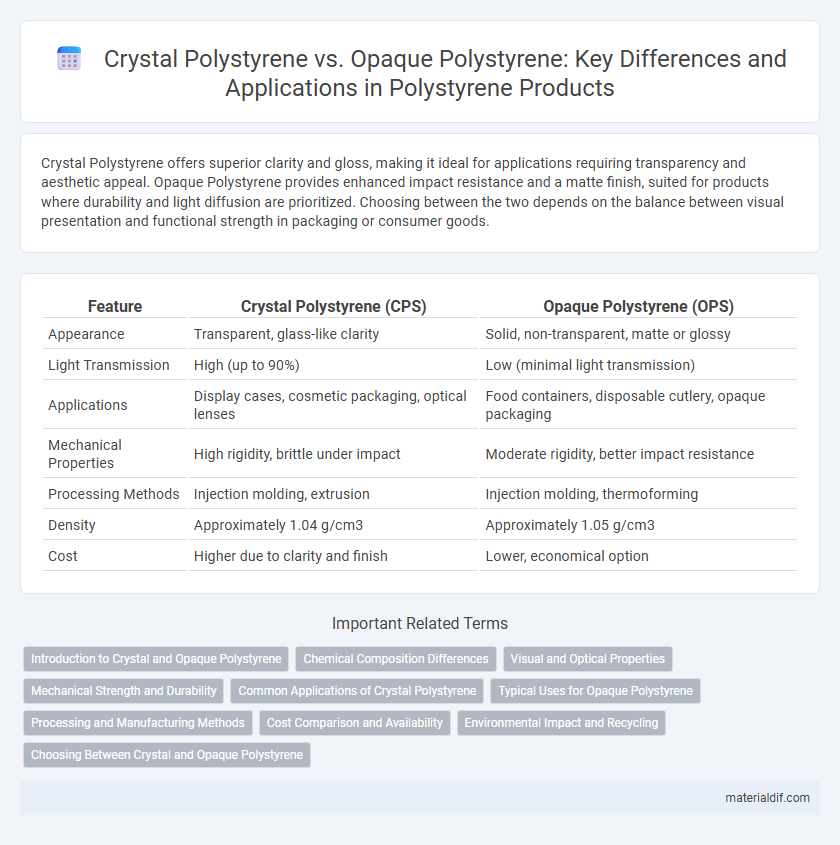

Crystal Polystyrene offers superior clarity and gloss, making it ideal for applications requiring transparency and aesthetic appeal. Opaque Polystyrene provides enhanced impact resistance and a matte finish, suited for products where durability and light diffusion are prioritized. Choosing between the two depends on the balance between visual presentation and functional strength in packaging or consumer goods.

Table of Comparison

| Feature | Crystal Polystyrene (CPS) | Opaque Polystyrene (OPS) |

|---|---|---|

| Appearance | Transparent, glass-like clarity | Solid, non-transparent, matte or glossy |

| Light Transmission | High (up to 90%) | Low (minimal light transmission) |

| Applications | Display cases, cosmetic packaging, optical lenses | Food containers, disposable cutlery, opaque packaging |

| Mechanical Properties | High rigidity, brittle under impact | Moderate rigidity, better impact resistance |

| Processing Methods | Injection molding, extrusion | Injection molding, thermoforming |

| Density | Approximately 1.04 g/cm3 | Approximately 1.05 g/cm3 |

| Cost | Higher due to clarity and finish | Lower, economical option |

Introduction to Crystal and Opaque Polystyrene

Crystal Polystyrene is a transparent, rigid thermoplastic widely used for clear packaging and display purposes due to its excellent clarity and gloss. Opaque Polystyrene, on the other hand, is characterized by its solid, non-transparent appearance and is commonly utilized for applications requiring structural strength and decorative finishes. Both variants offer distinct physical properties suited for specific industrial uses, with Crystal emphasizing optical clarity and Opaque focusing on durability and aesthetic versatility.

Chemical Composition Differences

Crystal polystyrene is composed primarily of a linear polymer structure with minimal additives, resulting in a transparent, glass-like appearance. Opaque polystyrene contains added fillers, pigments, or crystallinity modifiers that scatter light, creating its non-transparent, milky look. These chemical composition differences influence their optical properties and applications in packaging and consumer products.

Visual and Optical Properties

Crystal polystyrene exhibits superior clarity and transparency, making it ideal for applications requiring high optical purity and light transmission. In contrast, opaque polystyrene is designed with additives that diffuse light, resulting in a frosted or solid appearance that limits visibility through the material. The optical properties of crystal polystyrene enhance visual appeal and brightness, whereas opaque polystyrene provides consistent color coverage and hides contents effectively.

Mechanical Strength and Durability

Crystal Polystyrene exhibits higher mechanical strength due to its transparent, rigid structure, making it ideal for applications requiring clarity and moderate impact resistance. Opaque Polystyrene, although less transparent, offers enhanced durability and better resistance to fatigue and chemical exposure, suitable for long-term use in harsh environments. The choice between crystal and opaque varieties depends on balancing the need for strength, durability, and visual properties in specific industrial or consumer applications.

Common Applications of Crystal Polystyrene

Crystal Polystyrene is widely used in packaging applications such as clear food containers, cosmetic cases, and display boxes due to its excellent transparency and rigidity. Its clarity allows for high visibility of products, making it ideal for retail packaging and presentation purposes. In contrast, opaque polystyrene is more commonly utilized in applications where light blocking or insulation is required, such as disposable cutlery and protective housings.

Typical Uses for Opaque Polystyrene

Opaque polystyrene is commonly used in applications requiring durability and a non-transparent finish, such as in disposable cutlery, CD and DVD cases, and plastic containers for food storage. Its ability to provide a smooth, matte surface makes it ideal for printing and labeling, enhancing the product's aesthetic appeal. This versatility in manufacturing contributes to opaque polystyrene's widespread use in household and packaging products.

Processing and Manufacturing Methods

Crystal polystyrene is processed primarily through injection molding and extrusion, allowing for precise control over transparency and surface finish, making it ideal for applications requiring optical clarity. Opaque polystyrene, often enhanced with additives or pigments during compounding, is manufactured using similar techniques but optimized for strength, durability, and impact resistance rather than clarity. Both types require careful temperature regulation during processing to prevent degradation, with crystal grades demanding more stringent controls to maintain their transparent qualities.

Cost Comparison and Availability

Crystal polystyrene, known for its clarity and smooth finish, generally commands a higher price due to more intensive manufacturing processes, whereas opaque polystyrene offers a cost-effective alternative with broader availability in bulk quantities. Availability of crystal polystyrene tends to be limited to specialized suppliers and smaller production runs, impacting lead times and increasing costs in some regions. Opaque polystyrene is widely stocked by distributors and manufacturing plants, making it more accessible and affordable for large-scale industrial applications.

Environmental Impact and Recycling

Crystal polystyrene, known for its transparency, is generally easier to recycle because it can be reprocessed into clear products without significant quality loss, reducing environmental impact. Opaque polystyrene, often pigmented or mixed with additives, poses recycling challenges as it contaminates recycling streams and typically ends up in landfills or incinerators. Effective recycling programs that separate crystal and opaque polystyrene enhance resource recovery and minimize environmental pollution.

Choosing Between Crystal and Opaque Polystyrene

Crystal polystyrene offers high transparency and gloss, making it ideal for applications requiring clear, visually appealing displays or packaging. Opaque polystyrene provides enhanced durability and is better suited for products where light diffusion or color uniformity is essential. Selecting between crystal and opaque polystyrene depends on the balance between aesthetic clarity and functional strength required for the specific project.

Crystal Polystyrene vs Opaque Polystyrene Infographic

materialdif.com

materialdif.com