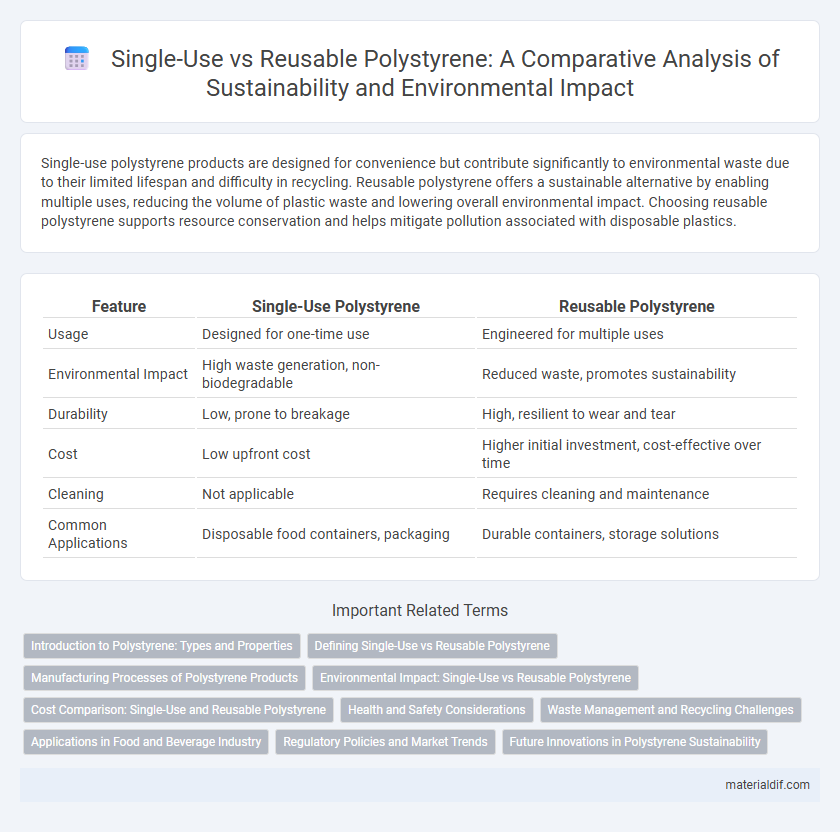

Single-use polystyrene products are designed for convenience but contribute significantly to environmental waste due to their limited lifespan and difficulty in recycling. Reusable polystyrene offers a sustainable alternative by enabling multiple uses, reducing the volume of plastic waste and lowering overall environmental impact. Choosing reusable polystyrene supports resource conservation and helps mitigate pollution associated with disposable plastics.

Table of Comparison

| Feature | Single-Use Polystyrene | Reusable Polystyrene |

|---|---|---|

| Usage | Designed for one-time use | Engineered for multiple uses |

| Environmental Impact | High waste generation, non-biodegradable | Reduced waste, promotes sustainability |

| Durability | Low, prone to breakage | High, resilient to wear and tear |

| Cost | Low upfront cost | Higher initial investment, cost-effective over time |

| Cleaning | Not applicable | Requires cleaning and maintenance |

| Common Applications | Disposable food containers, packaging | Durable containers, storage solutions |

Introduction to Polystyrene: Types and Properties

Polystyrene exists primarily in two forms: single-use and reusable, each with distinct properties tailored for specific applications. Single-use polystyrene, often found in disposable packaging and foam cups, is lightweight and rigid but lacks durability and recyclability. Reusable polystyrene variants are engineered for enhanced strength, thermal insulation, and environmental resistance, making them suitable for prolonged use and repeated handling.

Defining Single-Use vs Reusable Polystyrene

Single-use polystyrene consists of lightweight, disposable items such as food containers and packaging designed for one-time use before disposal. Reusable polystyrene products are manufactured for multiple uses and often feature thicker, more durable material to withstand cleaning and handling. Differentiating these types hinges on their lifecycle, environmental impact, and intended usage patterns in consumption.

Manufacturing Processes of Polystyrene Products

Single-use polystyrene products are typically manufactured through injection molding or foam expansion processes that optimize cost-effectiveness and mass production speed, resulting in lightweight and disposable items like food containers and cutlery. Reusable polystyrene products undergo more robust manufacturing techniques, including enhanced molding precision and post-production treatments, to increase durability and resistance to wear and chemical degradation. The differing manufacturing processes directly impact the environmental footprint, recyclability, and lifecycle performance of single-use versus reusable polystyrene items.

Environmental Impact: Single-Use vs Reusable Polystyrene

Single-use polystyrene contributes significantly to environmental pollution due to its non-biodegradable nature and high volume of waste generation, often ending up in landfills and oceans. Reusable polystyrene reduces this impact by minimizing waste production and resource consumption through repeated use, although it requires proper cleaning to prevent contamination. Lifecycle analyses indicate that reusable polystyrene offers a lower carbon footprint and less environmental degradation compared to single-use counterparts.

Cost Comparison: Single-Use and Reusable Polystyrene

Single-use polystyrene products typically have lower initial costs, making them economically attractive for short-term use, but they accumulate higher long-term expenses due to waste management and environmental impact fees. Reusable polystyrene items involve higher upfront investment yet offer significant cost savings over time through durability and reduced disposal costs. Analyzing lifecycle costs reveals that reusable polystyrene significantly reduces overall expenditure despite its initial price premium.

Health and Safety Considerations

Single-use polystyrene products often raise concerns due to potential chemical leaching, especially when exposed to heat, which can pose health risks like endocrine disruption. Reusable polystyrene items, if properly cleaned and maintained, reduce waste but may still harbor bacteria if not sanitized effectively, impacting safety. Understanding the differences in microbial contamination and chemical exposure is critical for making informed choices about polystyrene use in food and beverage contexts.

Waste Management and Recycling Challenges

Single-use polystyrene products contribute significantly to plastic waste due to their lightweight nature and low recycling rates, often ending up in landfills or oceans where they persist for centuries. Reusable polystyrene items, while reducing overall waste, face challenges in cleaning, durability, and contamination that complicate recycling processes. Waste management systems struggle with limited infrastructure for efficient polystyrene recycling, resulting in poor recovery rates and environmental pollution.

Applications in Food and Beverage Industry

Single-use polystyrene is widely used for disposable food containers, cups, and cutlery due to its lightweight and insulating properties, offering convenience in fast food and takeout services. Reusable polystyrene products, designed for durability and multiple cycles of use, are increasingly adopted in cafeterias and catering to reduce waste and environmental impact. Both types maintain thermal insulation and moisture resistance, but reusable options provide a sustainable alternative by minimizing single-use plastic consumption in the food and beverage industry.

Regulatory Policies and Market Trends

Regulatory policies increasingly restrict single-use polystyrene due to environmental concerns, with bans implemented in over 30 countries targeting disposable food containers and packaging. Market trends reveal a growing shift towards reusable polystyrene products, driven by consumer demand for sustainable alternatives and corporate commitments to reduce plastic waste. Innovations in recycling technologies and extended producer responsibility (EPR) programs are accelerating the adoption of reusable polystyrene in both domestic and commercial sectors.

Future Innovations in Polystyrene Sustainability

Future innovations in polystyrene sustainability emphasize biodegradable additives and advanced recycling technologies to reduce environmental impact of single-use polystyrene products. Research into reusable polystyrene variants incorporates enhanced durability and chemical resistance for extended lifecycle applications. Emerging methods like chemical recycling and bio-based polystyrene precursors aim to close the material loop and promote circular economy principles.

Single-Use Polystyrene vs Reusable Polystyrene Infographic

materialdif.com

materialdif.com