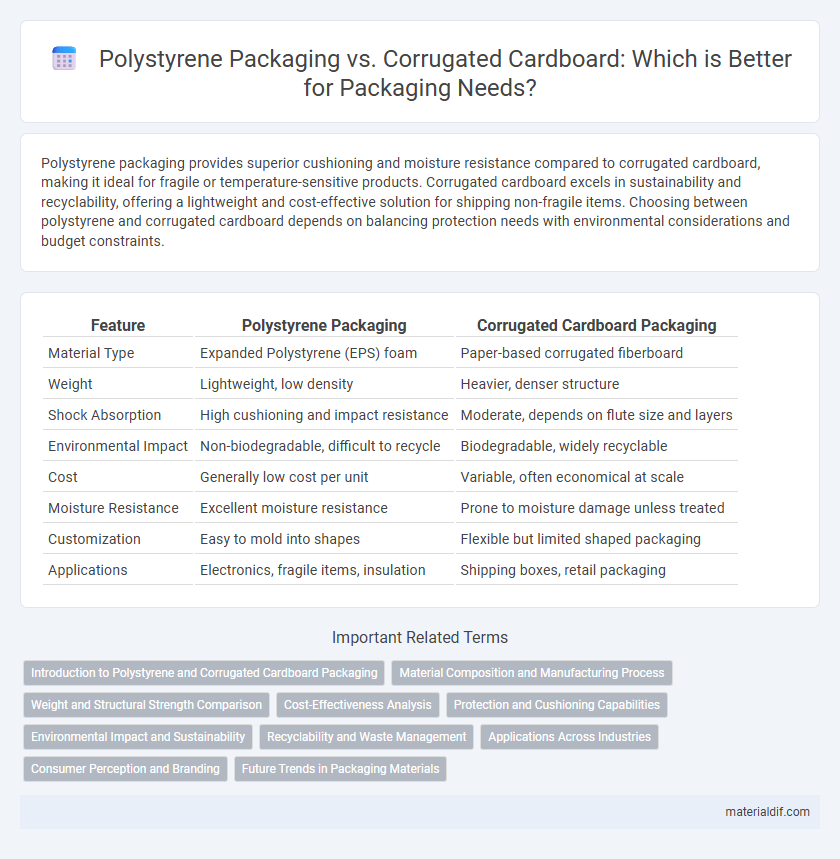

Polystyrene packaging provides superior cushioning and moisture resistance compared to corrugated cardboard, making it ideal for fragile or temperature-sensitive products. Corrugated cardboard excels in sustainability and recyclability, offering a lightweight and cost-effective solution for shipping non-fragile items. Choosing between polystyrene and corrugated cardboard depends on balancing protection needs with environmental considerations and budget constraints.

Table of Comparison

| Feature | Polystyrene Packaging | Corrugated Cardboard Packaging |

|---|---|---|

| Material Type | Expanded Polystyrene (EPS) foam | Paper-based corrugated fiberboard |

| Weight | Lightweight, low density | Heavier, denser structure |

| Shock Absorption | High cushioning and impact resistance | Moderate, depends on flute size and layers |

| Environmental Impact | Non-biodegradable, difficult to recycle | Biodegradable, widely recyclable |

| Cost | Generally low cost per unit | Variable, often economical at scale |

| Moisture Resistance | Excellent moisture resistance | Prone to moisture damage unless treated |

| Customization | Easy to mold into shapes | Flexible but limited shaped packaging |

| Applications | Electronics, fragile items, insulation | Shipping boxes, retail packaging |

Introduction to Polystyrene and Corrugated Cardboard Packaging

Polystyrene packaging consists of a lightweight, rigid plastic formed from styrene monomers, widely used for insulation and protective cushioning due to its excellent shock absorption and moisture resistance. Corrugated cardboard packaging features sturdy, layered paperboard composed of a fluted corrugated sheet sandwiched between two linerboards, known for its recyclability, structural strength, and cost-effectiveness in shipping applications. Both materials serve distinct packaging needs, with polystyrene excelling in impact protection and corrugated cardboard providing sustainable, versatile packaging solutions.

Material Composition and Manufacturing Process

Polystyrene packaging is composed of a synthetic aromatic hydrocarbon polymer derived from styrene monomers, characterized by its lightweight, rigid foam structure produced through polymerization and expansion processes. In contrast, corrugated cardboard packaging consists of cellulose fibers arranged in a fluted corrugated sheet, manufactured by bonding layers of paperboard using adhesives in a corrugator machine that forms the characteristic fluted inner layer for strength and cushioning. The manufacturing of polystyrene involves chemical polymerization and steam expansion, whereas corrugated cardboard production relies on mechanical pulping, layering, and corrugation without chemical polymerization.

Weight and Structural Strength Comparison

Polystyrene packaging offers a significantly lighter weight compared to corrugated cardboard, making it ideal for reducing shipping costs and improving handling efficiency. Despite its lightness, polystyrene exhibits superior structural strength and impact resistance, providing enhanced protection for fragile products during transit. Corrugated cardboard, while heavier, offers better sustainability and recycling options but generally requires additional reinforcement to match the load-bearing capabilities of polystyrene.

Cost-Effectiveness Analysis

Polystyrene packaging typically offers a lower initial cost and superior insulation properties compared to corrugated cardboard, making it ideal for temperature-sensitive products. Corrugated cardboard packaging, while generally more expensive upfront, provides better recyclability and structural strength, reducing long-term waste disposal costs and potential product damage. An effective cost-effectiveness analysis considers both material costs and environmental impact, with polystyrene excelling in short-term savings and cardboard offering sustainability benefits that can lower total lifecycle expenses.

Protection and Cushioning Capabilities

Polystyrene packaging offers superior protection and cushioning due to its lightweight, rigid structure and excellent shock absorption properties, making it ideal for fragile and sensitive items. Corrugated cardboard packaging provides decent cushioning through its fluted layer design but falls short in impact resistance and moisture protection compared to polystyrene. The enhanced durability and insulation of polystyrene make it a preferred choice for high-value electronics and temperature-sensitive goods.

Environmental Impact and Sustainability

Polystyrene packaging generates significant environmental concerns due to its non-biodegradable nature and low recycling rates, contributing to persistent plastic pollution and landfill accumulation. Corrugated cardboard packaging offers enhanced sustainability through its biodegradability, higher recyclability, and reliance on renewable wood fiber sources. Life cycle assessments reveal that cardboard's lower carbon footprint and greater potential for reuse position it as a more eco-friendly alternative in packaging applications.

Recyclability and Waste Management

Polystyrene packaging, often criticized for its low recycling rate due to contamination and limited acceptance in curbside programs, poses significant challenges in waste management compared to corrugated cardboard packaging. Corrugated cardboard is widely recyclable, biodegradable, and commonly accepted in municipal recycling streams, enhancing its sustainability profile. The infrastructure for recycling corrugated cardboard is far more developed, resulting in higher recovery rates and more efficient waste diversion.

Applications Across Industries

Polystyrene packaging offers exceptional cushioning and moisture resistance, making it ideal for electronics, medical devices, and food products requiring sterile environments. Corrugated cardboard packaging excels in structural strength and recyclability, widely used for shipping consumer goods, retail products, and bulk industrial materials. Industries prioritize polystyrene for delicate item protection and corrugated cardboard for cost-effective, eco-friendly transportation solutions.

Consumer Perception and Branding

Polystyrene packaging is often perceived by consumers as lightweight, durable, and protective, enhancing the perceived value of fragile or temperature-sensitive products. Corrugated cardboard packaging is favored for its eco-friendly image and recyclability, which aligns with the growing consumer demand for sustainability and environmentally responsible branding. Brands using polystyrene may face challenges in appealing to eco-conscious customers, while corrugated cardboard packaging reinforces a green brand identity and boosts consumer trust.

Future Trends in Packaging Materials

Polystyrene packaging is evolving with innovations aimed at enhancing recyclability and reducing environmental impact, such as bio-based and biodegradable variants. Corrugated cardboard packaging continues to lead in sustainability due to its renewable resources and widespread recyclability, with advancements in water-resistant coatings and structural strength. Future trends emphasize eco-friendly materials, lightweight designs, and smart packaging features that improve protection and reduce carbon footprints across both polystyrene and corrugated cardboard sectors.

Polystyrene Packaging vs Corrugated Cardboard Packaging Infographic

materialdif.com

materialdif.com