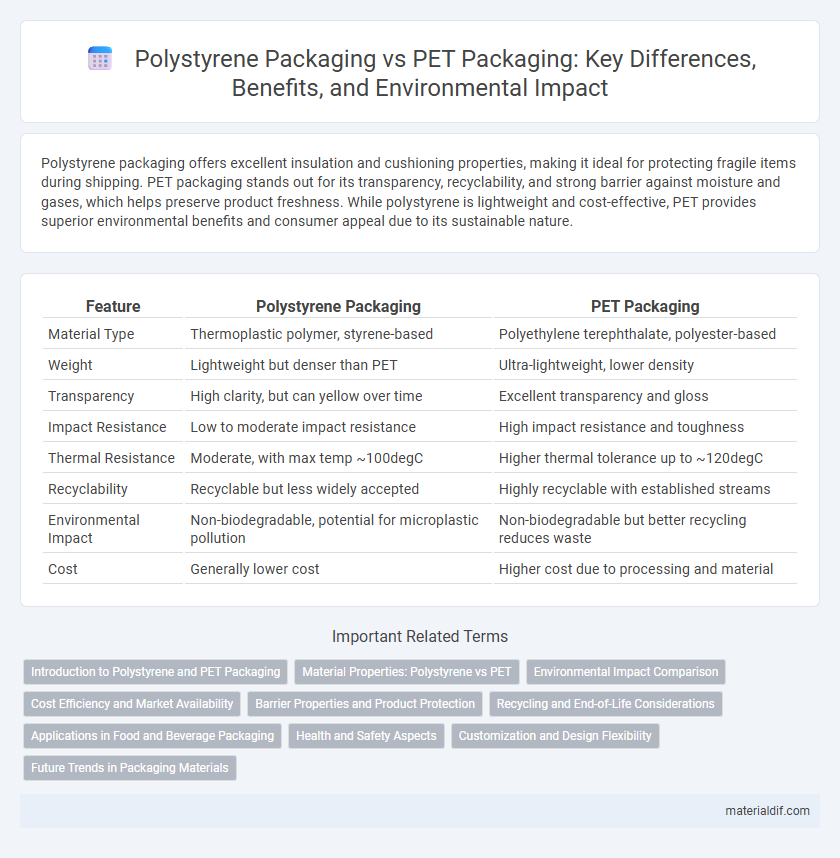

Polystyrene packaging offers excellent insulation and cushioning properties, making it ideal for protecting fragile items during shipping. PET packaging stands out for its transparency, recyclability, and strong barrier against moisture and gases, which helps preserve product freshness. While polystyrene is lightweight and cost-effective, PET provides superior environmental benefits and consumer appeal due to its sustainable nature.

Table of Comparison

| Feature | Polystyrene Packaging | PET Packaging |

|---|---|---|

| Material Type | Thermoplastic polymer, styrene-based | Polyethylene terephthalate, polyester-based |

| Weight | Lightweight but denser than PET | Ultra-lightweight, lower density |

| Transparency | High clarity, but can yellow over time | Excellent transparency and gloss |

| Impact Resistance | Low to moderate impact resistance | High impact resistance and toughness |

| Thermal Resistance | Moderate, with max temp ~100degC | Higher thermal tolerance up to ~120degC |

| Recyclability | Recyclable but less widely accepted | Highly recyclable with established streams |

| Environmental Impact | Non-biodegradable, potential for microplastic pollution | Non-biodegradable but better recycling reduces waste |

| Cost | Generally lower cost | Higher cost due to processing and material |

Introduction to Polystyrene and PET Packaging

Polystyrene packaging is a versatile and lightweight material commonly used for food containers, insulation, and disposable cups due to its excellent thermal insulation and impact resistance. PET (polyethylene terephthalate) packaging is widely preferred for beverages and food products because of its clarity, strength, and recyclability. Both materials play crucial roles in the packaging industry, with polystyrene offering cost-effective cushioning and PET providing durability and enhanced sustainability.

Material Properties: Polystyrene vs PET

Polystyrene packaging offers excellent rigidity and thermal insulation properties, making it ideal for protecting fragile items and maintaining temperature-sensitive products. PET packaging is known for its superior tensile strength, clarity, and chemical resistance, which enhances product visibility and durability during transport. Both materials are lightweight and recyclable, but PET has higher impact resistance and gas barrier properties, extending shelf life for perishable goods.

Environmental Impact Comparison

Polystyrene packaging generates significantly more non-biodegradable waste compared to PET packaging, contributing to long-term environmental pollution. PET packaging is widely recycled, reducing landfill volume and lowering carbon footprint, whereas polystyrene recycling rates remain low due to higher processing costs and contamination issues. Life cycle analyses reveal that PET's environmental impact is substantially lessened with efficient recycling systems, making it a more sustainable option for packaging materials.

Cost Efficiency and Market Availability

Polystyrene packaging offers superior cost efficiency due to lower material and production expenses compared to PET packaging, making it a preferred option for budget-sensitive applications. Polystyrene's lightweight nature reduces shipping costs and enhances market availability through widespread manufacturing facilities globally. PET packaging, while slightly more expensive, is favored in markets prioritizing recyclability and sustainability, influencing its distribution and prevalence.

Barrier Properties and Product Protection

Polystyrene packaging offers excellent oxygen and moisture barrier properties, making it ideal for protecting perishable goods and maintaining product freshness. In comparison, PET packaging provides superior strength and chemical resistance but generally exhibits higher permeability to gases, potentially reducing shelf life for sensitive items. Optimizing barrier performance depends on the specific application requirements, with polystyrene often preferred for short-term preservation and PET favored for durability and extended storage.

Recycling and End-of-Life Considerations

Polystyrene packaging presents challenges in recycling due to its bulky nature and limited acceptance in municipal programs, leading to higher landfill rates compared to PET packaging, which is widely recyclable and supported by extensive recycling infrastructure. End-of-life considerations favor PET as it can be efficiently processed into new products, reducing plastic waste and environmental impact, while polystyrene often requires specialized recycling facilities that are less accessible. Innovations in polystyrene recycling are emerging but currently, PET remains the more sustainable option for packaging disposal and circular economy integration.

Applications in Food and Beverage Packaging

Polystyrene packaging excels in protecting food items with excellent insulation and cushioning, making it ideal for products like meat trays, egg cartons, and disposable coffee cups. PET packaging offers superior clarity, strength, and barrier properties, commonly used for bottles, jars, and containers that require extended shelf life for beverages and condiments. Both materials meet food safety standards but differ in recycling challenges and environmental impact, influencing their application in sustainable packaging solutions.

Health and Safety Aspects

Polystyrene packaging offers excellent insulation and shock absorption, but concerns over styrene leaching raise potential health risks, especially when exposed to heat or fatty foods. PET packaging is generally considered safer for food contact due to its inert chemical properties and resistance to leaching harmful substances under typical use conditions. Regulatory agencies often recommend PET for beverages and perishable goods to minimize the risk of contaminants affecting consumer health.

Customization and Design Flexibility

Polystyrene packaging offers significant customization options with its ease of molding into intricate shapes and detailed designs, making it ideal for specialized applications requiring precise fit and aesthetic appeal. PET packaging, while highly durable and clear, provides less flexibility in complex shapes but excels in producing consistent, lightweight containers suitable for mass production. Custom design capabilities of polystyrene contribute to enhanced product protection and brand differentiation, particularly in sectors like electronics and food packaging.

Future Trends in Packaging Materials

Polystyrene packaging remains favored for its lightweight insulation properties and cost-effectiveness, yet PET packaging gains momentum due to its superior recyclability and environmental profile. Innovations in biodegradable additives and advanced polymer blends are driving the evolution of both materials, aiming to meet stricter sustainability regulations and consumer demand for eco-friendly solutions. Future trends forecast a hybrid approach integrating polystyrene's functional benefits with PET's recyclability, enhancing circular economy efforts in the packaging industry.

Polystyrene Packaging vs PET Packaging Infographic

materialdif.com

materialdif.com