Polystyrene (PS) is a versatile plastic known for its clarity and rigidity, commonly used in packaging and disposable containers. High Impact Polystyrene (HIPS) incorporates rubber to enhance toughness and impact resistance, making it ideal for durable products like appliance housings and toys. While standard polystyrene excels in cost-effectiveness and ease of molding, HIPS offers superior strength and durability for applications requiring greater resilience.

Table of Comparison

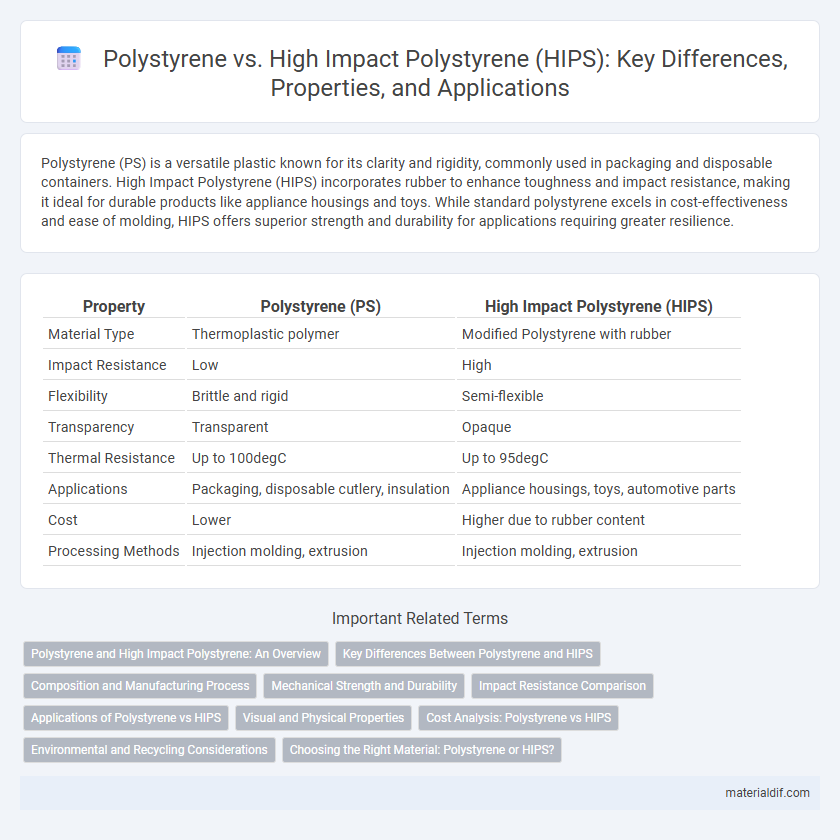

| Property | Polystyrene (PS) | High Impact Polystyrene (HIPS) |

|---|---|---|

| Material Type | Thermoplastic polymer | Modified Polystyrene with rubber |

| Impact Resistance | Low | High |

| Flexibility | Brittle and rigid | Semi-flexible |

| Transparency | Transparent | Opaque |

| Thermal Resistance | Up to 100degC | Up to 95degC |

| Applications | Packaging, disposable cutlery, insulation | Appliance housings, toys, automotive parts |

| Cost | Lower | Higher due to rubber content |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion |

Polystyrene and High Impact Polystyrene: An Overview

Polystyrene is a versatile thermoplastic polymer known for its clarity, rigidity, and ease of molding, commonly used in packaging, disposable cutlery, and insulation. High Impact Polystyrene (HIPS) incorporates rubber additives to enhance toughness and impact resistance, making it suitable for applications requiring greater durability such as appliance housings and automotive parts. The molecular structure differences result in Polystyrene being more brittle and transparent, whereas HIPS offers improved mechanical strength and a matte finish while maintaining ease of processing.

Key Differences Between Polystyrene and HIPS

Polystyrene (PS) is a rigid, brittle thermoplastic commonly used for packaging and disposable containers, while High Impact Polystyrene (HIPS) is enhanced with rubber additives to provide increased impact resistance and flexibility. HIPS retains much of polystyrene's ease of processing and clarity but offers superior toughness, making it suitable for applications requiring durability such as appliance housings and automotive parts. The primary difference lies in HIPS's improved mechanical properties, especially impact strength, compared to the standard polystyrene's stiffness and brittleness.

Composition and Manufacturing Process

Polystyrene is a polymer made from the styrene monomer, produced through free-radical polymerization, resulting in a rigid and brittle thermoplastic. High Impact Polystyrene (HIPS) incorporates rubber particles, typically polybutadiene, within the styrene matrix via graft copolymerization, enhancing its impact resistance. Manufacturing HIPS involves a rubber-modified polymerization process that creates a two-phase structure, providing increased toughness compared to standard polystyrene.

Mechanical Strength and Durability

Polystyrene (PS) is a rigid, brittle plastic with moderate mechanical strength, making it suitable for lightweight packaging and disposable containers. High Impact Polystyrene (HIPS) is modified with rubber to significantly enhance impact resistance and durability, providing better toughness under stress and improved resistance to cracking. HIPS combines the processability of polystyrene with superior mechanical strength, making it ideal for applications requiring higher durability and impact performance.

Impact Resistance Comparison

Polystyrene (PS) exhibits moderate impact resistance, making it suitable for applications requiring rigidity but limited toughness. High Impact Polystyrene (HIPS) incorporates elastomeric modifiers, enhancing its impact resistance significantly compared to standard PS. This increased toughness in HIPS makes it ideal for products subjected to higher mechanical stress or impact forces.

Applications of Polystyrene vs HIPS

Polystyrene is widely used in packaging, disposable cutlery, and insulation due to its rigidity and clarity, while High Impact Polystyrene (HIPS) is preferred in applications requiring greater durability, such as automotive parts, appliance housings, and consumer electronics casings. HIPS offers enhanced impact resistance and toughness compared to standard polystyrene, making it suitable for products exposed to mechanical stress. The choice between Polystyrene and HIPS depends on the need for strength versus aesthetics and cost efficiency in manufacturing.

Visual and Physical Properties

Polystyrene (PS) is a transparent, brittle thermoplastic with excellent rigidity and a smooth surface finish, commonly used in packaging and disposable containers. High Impact Polystyrene (HIPS) enhances polystyrene's mechanical properties by incorporating rubber, resulting in increased impact resistance and toughness while maintaining good dimensional stability. Visually, HIPS is often opaque or matte due to rubber content, contrasting with the clear, glossy appearance of standard polystyrene.

Cost Analysis: Polystyrene vs HIPS

Polystyrene typically costs less than High Impact Polystyrene (HIPS) due to its simpler polymer structure and lower production expenses. HIPS incorporates rubber modifiers to enhance impact resistance, resulting in higher raw material and processing costs. The choice between Polystyrene and HIPS therefore depends on balancing cost considerations with mechanical performance requirements for specific applications.

Environmental and Recycling Considerations

Polystyrene (PS) is widely used but poses environmental challenges due to its non-biodegradable nature and difficulty in recycling, often ending up in landfills or oceans. High Impact Polystyrene (HIPS) incorporates rubber particles, making it tougher but complicating recycling processes and reducing recyclability compared to standard polystyrene. Both materials require specialized recycling streams, with HIPS demanding more advanced separation techniques to address its composite structure and improve environmental outcomes.

Choosing the Right Material: Polystyrene or HIPS?

Polystyrene offers excellent clarity and rigidity, making it ideal for applications requiring transparency and lightweight properties such as packaging and disposable cutlery. High Impact Polystyrene (HIPS) provides enhanced strength and impact resistance, suitable for products like appliance housings and automotive components that demand durability. Selecting between polystyrene and HIPS depends on balancing budget, mechanical performance, and the specific needs of the end-use environment.

Polystyrene vs High Impact Polystyrene (HIPS) Infographic

materialdif.com

materialdif.com