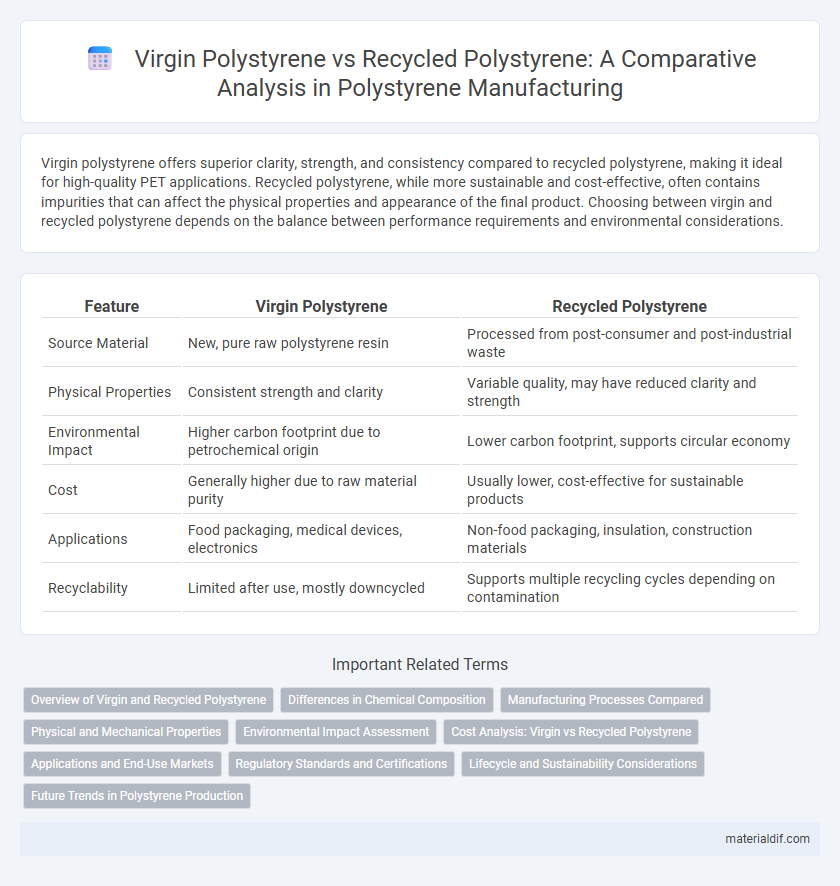

Virgin polystyrene offers superior clarity, strength, and consistency compared to recycled polystyrene, making it ideal for high-quality PET applications. Recycled polystyrene, while more sustainable and cost-effective, often contains impurities that can affect the physical properties and appearance of the final product. Choosing between virgin and recycled polystyrene depends on the balance between performance requirements and environmental considerations.

Table of Comparison

| Feature | Virgin Polystyrene | Recycled Polystyrene |

|---|---|---|

| Source Material | New, pure raw polystyrene resin | Processed from post-consumer and post-industrial waste |

| Physical Properties | Consistent strength and clarity | Variable quality, may have reduced clarity and strength |

| Environmental Impact | Higher carbon footprint due to petrochemical origin | Lower carbon footprint, supports circular economy |

| Cost | Generally higher due to raw material purity | Usually lower, cost-effective for sustainable products |

| Applications | Food packaging, medical devices, electronics | Non-food packaging, insulation, construction materials |

| Recyclability | Limited after use, mostly downcycled | Supports multiple recycling cycles depending on contamination |

Overview of Virgin and Recycled Polystyrene

Virgin polystyrene consists of newly synthesized polymer beads derived from styrene monomers, offering consistent quality, clarity, and mechanical properties ideal for high-precision applications. Recycled polystyrene is produced from post-consumer or post-industrial polystyrene waste that undergoes cleaning, pelletizing, and reforming processes, often exhibiting slight variations in color and mechanical strength. Both forms serve in packaging, insulation, and consumer goods, but virgin polystyrene ensures higher purity and performance while recycled polystyrene contributes to cost efficiency and environmental sustainability.

Differences in Chemical Composition

Virgin polystyrene consists of pure styrene monomers with consistent polymer chains, resulting in uniform thermal and mechanical properties. Recycled polystyrene contains a mixture of polymers and contaminants from previous uses, leading to variations in molecular weight and potential degradation of polymer chains. These differences affect the material's clarity, strength, and processing behavior in manufacturing applications.

Manufacturing Processes Compared

Virgin polystyrene is produced through the polymerization of styrene monomers under controlled conditions, ensuring consistent molecular weight and purity, which results in superior mechanical and optical properties. Recycled polystyrene manufacturing involves collecting, sorting, cleaning, and melting post-consumer or post-industrial polystyrene waste, often leading to material degradation, contamination, and limitations in color and strength. Advanced recycling techniques such as pyrolysis and chemical recycling are being developed to address issues in traditional mechanical recycling, aiming to restore virgin-like quality in recycled polystyrene resin.

Physical and Mechanical Properties

Virgin polystyrene exhibits superior mechanical properties such as higher tensile strength, impact resistance, and elongation at break compared to recycled polystyrene, which often suffers from property degradation due to polymer chain scission and contamination during recycling. Physical characteristics like density and thermal stability remain relatively consistent between virgin and recycled forms, though recycled polystyrene can show slight discoloration and increased brittleness. These differences significantly influence the suitability of virgin versus recycled polystyrene in applications demanding high durability and dimensional stability.

Environmental Impact Assessment

Virgin polystyrene production relies on non-renewable petroleum resources and generates higher greenhouse gas emissions compared to recycled polystyrene, which reduces landfill waste and conserves raw materials. Recycling polystyrene lowers energy consumption by up to 70% relative to virgin production, significantly decreasing carbon footprint and resource depletion. Environmental impact assessments highlight that utilizing recycled polystyrene supports a circular economy, minimizes pollution, and promotes sustainable material management.

Cost Analysis: Virgin vs Recycled Polystyrene

Virgin polystyrene typically incurs higher production costs due to raw material extraction and energy consumption, whereas recycled polystyrene benefits from lower input costs by utilizing post-consumer or industrial waste streams. Market prices for virgin polystyrene average around $1,500 to $2,000 per ton, while recycled variants fluctuate between $800 to $1,200 per ton, reflecting savings in feedstock but potential expenses in sorting and contamination removal. Cost efficiency in recycled polystyrene is influenced by recycling technology advancements and local recycling infrastructure, which can significantly reduce processing and supply chain costs.

Applications and End-Use Markets

Virgin polystyrene exhibits superior clarity, strength, and processability suited for high-end packaging, food containers, and medical devices, ensuring product safety and aesthetic appeal. Recycled polystyrene primarily serves construction insulation, automotive components, and non-food packaging markets due to its slightly reduced mechanical properties and contamination risk. Market demand shifts toward recycled polystyrene stem from sustainability initiatives, with applications expanding as recycling technologies improve material quality and performance consistency.

Regulatory Standards and Certifications

Virgin polystyrene must comply with strict regulatory standards such as FDA and EU food contact approvals, ensuring high purity and safety for consumer products. Recycled polystyrene often faces challenges in meeting these certifications due to potential contamination and material degradation during processing. Certification bodies like ISO and ASTM provide guidelines, but recycled polystyrene requires rigorous testing to achieve compliance comparable to virgin material.

Lifecycle and Sustainability Considerations

Virgin polystyrene is derived from petroleum-based raw materials, resulting in higher carbon emissions and energy consumption throughout its lifecycle compared to recycled polystyrene, which utilizes post-consumer waste, reducing landfill impact and resource depletion. The recycling process for polystyrene contributes to sustainability by lowering environmental footprints through material reuse, though it may face challenges like contamination and degradation affecting quality. Lifecycle assessments reveal that incorporating recycled polystyrene significantly improves eco-efficiency, supporting circular economy initiatives and reducing dependence on fossil fuels.

Future Trends in Polystyrene Production

Future trends in polystyrene production emphasize increased integration of recycled polystyrene to reduce environmental impact and dependence on virgin raw materials. Advancements in chemical recycling technologies enable higher purity recycled polystyrene, making it suitable for food-grade and high-performance applications. Industry forecasts project a growing shift toward circular economy models, with regulatory incentives driving innovation in sustainable polystyrene manufacturing.

Virgin Polystyrene vs Recycled Polystyrene Infographic

materialdif.com

materialdif.com