Polystyrene offers superior shatter resistance compared to acrylic, making it a safer choice for pet enclosures where durability is essential. While acrylic provides better clarity and UV resistance, polystyrene is more cost-effective and easier to fabricate for custom pet habitats. Choosing between polystyrene and acrylic depends on balancing durability, visual quality, and budget for your pet's environment.

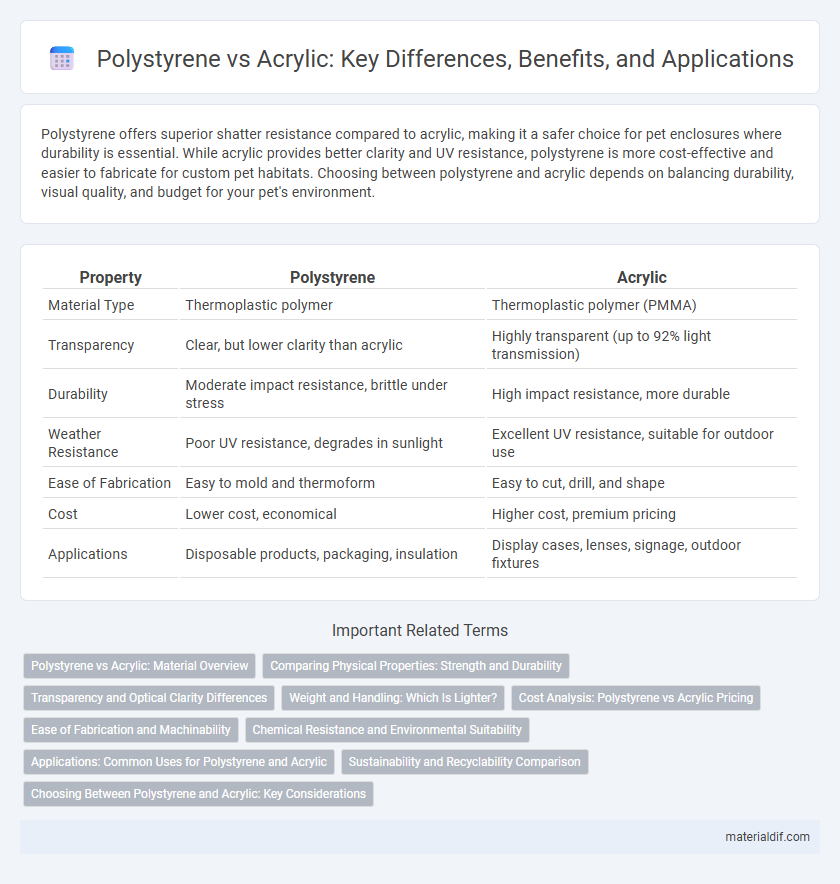

Table of Comparison

| Property | Polystyrene | Acrylic |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic polymer (PMMA) |

| Transparency | Clear, but lower clarity than acrylic | Highly transparent (up to 92% light transmission) |

| Durability | Moderate impact resistance, brittle under stress | High impact resistance, more durable |

| Weather Resistance | Poor UV resistance, degrades in sunlight | Excellent UV resistance, suitable for outdoor use |

| Ease of Fabrication | Easy to mold and thermoform | Easy to cut, drill, and shape |

| Cost | Lower cost, economical | Higher cost, premium pricing |

| Applications | Disposable products, packaging, insulation | Display cases, lenses, signage, outdoor fixtures |

Polystyrene vs Acrylic: Material Overview

Polystyrene offers rigidity and cost-effectiveness, making it ideal for disposable products and insulation, while acrylic provides superior clarity and weather resistance suited for displays and signage. Polystyrene has a lower impact resistance compared to acrylic, which is more durable and less prone to yellowing over time. Both materials are thermoplastics, but acrylic's enhanced optical properties and UV stability differentiate it from the more economical and easily molded polystyrene.

Comparing Physical Properties: Strength and Durability

Polystyrene exhibits lower tensile strength and impact resistance compared to acrylic, making it less suitable for applications requiring high durability. Acrylic offers superior hardness and resistance to weathering, which enhances its performance in outdoor and high-stress environments. The density of polystyrene is generally lower, contributing to its brittleness relative to the more resilient acrylic material.

Transparency and Optical Clarity Differences

Polystyrene offers good transparency with a light transmittance of about 92%, making it suitable for many general applications requiring clear visibility. Acrylic surpasses polystyrene in optical clarity, featuring higher light transmittance around 92-93% and superior resistance to yellowing, which maintains its clarity over time. The refractive index of acrylic is closer to that of glass, providing sharper visual clarity and better performance in optical applications compared to polystyrene.

Weight and Handling: Which Is Lighter?

Polystyrene weighs significantly less than acrylic, making it easier to handle and ideal for lightweight applications such as packaging and model-making. Its low density contributes to enhanced portability and reduced shipping costs compared to the denser, heavier acrylic sheets. Choosing polystyrene over acrylic facilitates easier installation and manipulation in projects where weight is a critical factor.

Cost Analysis: Polystyrene vs Acrylic Pricing

Polystyrene is significantly more cost-effective than acrylic, with prices typically ranging from $1 to $3 per square foot, making it a budget-friendly choice for large-scale projects. Acrylic, however, commands higher prices between $5 and $10 per square foot due to its superior optical clarity and durability. Cost analysis favors polystyrene for applications requiring economical materials without stringent performance demands.

Ease of Fabrication and Machinability

Polystyrene offers greater ease of fabrication compared to acrylic due to its lower melting point and softer texture, allowing for quicker cutting, shaping, and thermoforming processes. Machinability of polystyrene is superior as it responds well to conventional woodworking tools with minimal risk of cracking or chipping, unlike acrylic which requires specialized tools and slower speeds to prevent brittleness and melting. The combination of flexibility in fabrication and reliable machinability makes polystyrene a preferred choice for rapid prototyping and low-cost manufacturing applications.

Chemical Resistance and Environmental Suitability

Polystyrene demonstrates lower chemical resistance compared to acrylic, particularly against solvents like ketones and chlorinated hydrocarbons, which can cause polystyrene to crack or dissolve. Acrylic exhibits superior environmental suitability due to its UV resistance and ability to withstand outdoor exposure without yellowing or degrading. When selecting materials for applications involving harsh chemicals or prolonged environmental stress, acrylic is often preferred for its durability and stability.

Applications: Common Uses for Polystyrene and Acrylic

Polystyrene is widely used in packaging materials, disposable cutlery, insulation, and model-making due to its lightweight and cost-effectiveness. Acrylic finds application in optical devices, automotive parts, signage, and aquariums, favored for its excellent clarity and impact resistance. Both materials serve different industries, with polystyrene excelling in disposable and insulating products, while acrylic is preferred for durable, clear, and aesthetic applications.

Sustainability and Recyclability Comparison

Polystyrene and acrylic differ significantly in sustainability and recyclability; polystyrene, a petroleum-based plastic, is widely recyclable but often faces challenges due to contamination and low-density waste management costs. Acrylic, derived from acrylic acid, offers better durability and longevity, reducing replacement frequency and environmental impact despite being less commonly recycled in standard municipal programs. Advances in recycling technologies for both materials continue to improve their environmental footprints, with polystyrene benefiting from expanding chemical recycling processes and acrylic leveraging mechanical recycling methods.

Choosing Between Polystyrene and Acrylic: Key Considerations

Polystyrene offers excellent affordability and ease of fabrication, making it ideal for budget-conscious projects and prototypes, while acrylic provides superior clarity, UV resistance, and impact strength suited for long-lasting, high-performance applications. Consider environmental exposure, with acrylic preferred for outdoor use due to its weather resistance, whereas polystyrene suits indoor or short-term displays. Weight and rigidity requirements also influence choice, as polystyrene is lighter but less rigid than acrylic, affecting durability and structural stability.

Polystyrene vs Acrylic Infographic

materialdif.com

materialdif.com