Oriented polystyrene (OPS) exhibits enhanced mechanical properties and clarity compared to unoriented polystyrene due to the molecular alignment achieved during processing. This orientation improves stiffness, tensile strength, and impact resistance, making OPS suitable for packaging applications requiring durability and transparency. Unoriented polystyrene lacks this molecular alignment, resulting in lower strength and less optical clarity, typically used in applications where these properties are less critical.

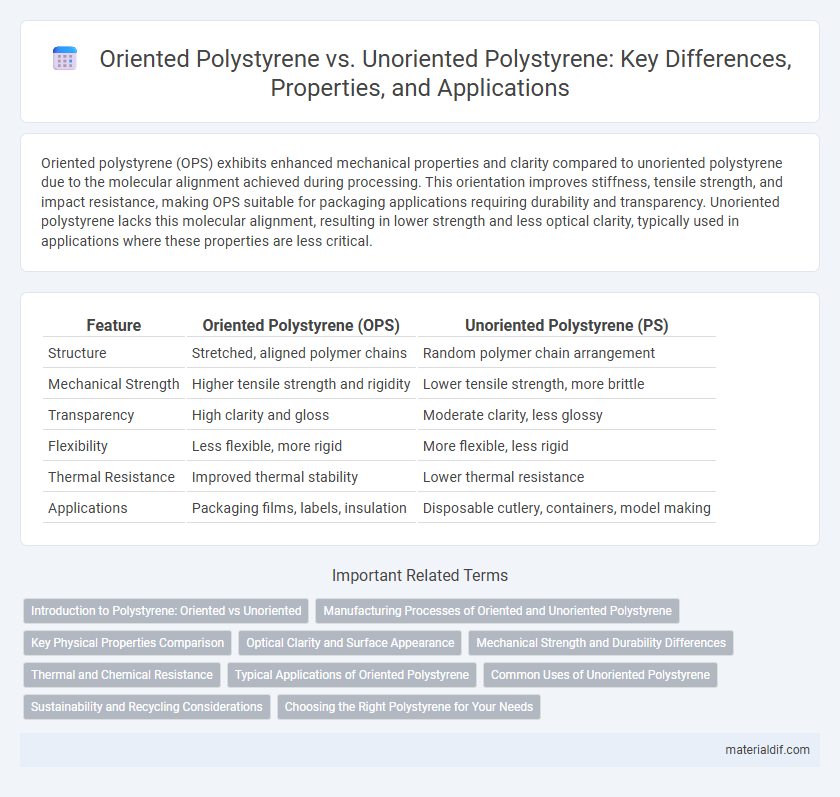

Table of Comparison

| Feature | Oriented Polystyrene (OPS) | Unoriented Polystyrene (PS) |

|---|---|---|

| Structure | Stretched, aligned polymer chains | Random polymer chain arrangement |

| Mechanical Strength | Higher tensile strength and rigidity | Lower tensile strength, more brittle |

| Transparency | High clarity and gloss | Moderate clarity, less glossy |

| Flexibility | Less flexible, more rigid | More flexible, less rigid |

| Thermal Resistance | Improved thermal stability | Lower thermal resistance |

| Applications | Packaging films, labels, insulation | Disposable cutlery, containers, model making |

Introduction to Polystyrene: Oriented vs Unoriented

Oriented polystyrene (OPS) exhibits enhanced mechanical strength and stiffness due to molecular alignment achieved through stretching during processing, making it ideal for packaging requiring durability. Unoriented polystyrene (PS) retains its amorphous, isotropic structure with lower tensile strength but superior clarity and ease of fabrication, commonly used in disposable containers and general-purpose applications. Understanding the differences in molecular orientation and corresponding physical properties is crucial for selecting the appropriate polystyrene type based on performance criteria and end-use requirements.

Manufacturing Processes of Oriented and Unoriented Polystyrene

Oriented polystyrene is manufactured through a biaxial stretching process that aligns polymer chains, enhancing strength, clarity, and barrier properties. In contrast, unoriented polystyrene is produced by conventional polymerization and extrusion without any mechanical stretching, resulting in isotropic properties. The manufacturing of oriented polystyrene requires precise temperature control and stretching ratios to optimize mechanical performance compared to the simpler, cost-effective process of unoriented polystyrene production.

Key Physical Properties Comparison

Oriented polystyrene (OPS) exhibits enhanced tensile strength and improved clarity compared to unoriented polystyrene due to molecular alignment achieved during stretching. Unoriented polystyrene typically has lower impact resistance and reduced dimensional stability under heat, making it less suitable for applications requiring mechanical durability. OPS also offers better barrier properties and stiffness, resulting from its anisotropic molecular structure that optimizes physical performance in packaging and consumer goods.

Optical Clarity and Surface Appearance

Oriented polystyrene exhibits superior optical clarity due to the molecular alignment achieved during the stretching process, resulting in a more transparent and reflective surface appearance. Unoriented polystyrene lacks this structural organization, leading to a hazier look with diminished light transmission and a matte finish. The enhanced surface smoothness and clarity of oriented polystyrene make it ideal for applications requiring high visual quality, such as packaging and display materials.

Mechanical Strength and Durability Differences

Oriented polystyrene (OPS) exhibits enhanced mechanical strength and durability compared to unoriented polystyrene due to the alignment of polymer chains during the stretching process, resulting in increased tensile strength and impact resistance. Unoriented polystyrene lacks this molecular alignment, leading to lower mechanical performance and reduced resistance to environmental stress cracking. OPS is preferred in applications requiring higher load-bearing capacity and improved dimensional stability, such as food packaging and rigid containers.

Thermal and Chemical Resistance

Oriented polystyrene (OPS) exhibits enhanced thermal stability due to the molecular alignment achieved during the orientation process, allowing it to withstand higher temperatures without deformation compared to unoriented polystyrene (HIPS). Chemically, OPS demonstrates improved resistance to solvents and environmental stress cracking, making it more suitable for applications requiring durability against chemicals. In contrast, unoriented polystyrene has lower thermal resistance and is more susceptible to chemical attack, limiting its use in demanding industrial settings.

Typical Applications of Oriented Polystyrene

Oriented polystyrene (OPS) is widely used in packaging applications such as food containers, disposable cutlery, and blister packs due to its enhanced strength, clarity, and barrier properties compared to unoriented polystyrene. The molecular orientation in OPS improves impact resistance and dimensional stability, making it ideal for protective packaging and display purposes. Typical products include yogurt cups, clam-shell containers, and clear lids, where transparency and rigidity are essential.

Common Uses of Unoriented Polystyrene

Unoriented polystyrene (OPS) is widely used in packaging applications such as food containers, disposable cutlery, and CD cases due to its cost-effectiveness and ease of molding. It offers good clarity and stiffness but lacks the enhanced strength and impact resistance found in oriented polystyrene. Common uses leverage OPS's rigidity for products requiring dimensional stability without the need for high tensile strength.

Sustainability and Recycling Considerations

Oriented polystyrene (OPS) exhibits enhanced mechanical properties compared to unoriented polystyrene, enabling thinner packaging and reduced material usage, which contributes to lower environmental impact. However, OPS's multi-layer orientation can complicate recycling processes, as the polymer chains' alignment affects melt flow and reprocessing efficiency. Unoriented polystyrene, while less mechanically robust, is more straightforward to recycle due to its isotropic structure, facilitating higher recycling rates and supporting circular economy initiatives in plastic waste management.

Choosing the Right Polystyrene for Your Needs

Oriented polystyrene (OPS) offers enhanced clarity, rigidity, and impact resistance due to molecular alignment during production, making it ideal for packaging that requires durability and transparency. Unoriented polystyrene, also known as general-purpose polystyrene (GPPS), provides a more economical option with good stiffness but lower impact strength and clarity, suited for applications like disposable cutlery and CD cases. Selecting the right polystyrene depends on balancing factors such as mechanical properties, appearance, and cost requirements for your specific use case.

Oriented Polystyrene vs Unoriented Polystyrene Infographic

materialdif.com

materialdif.com