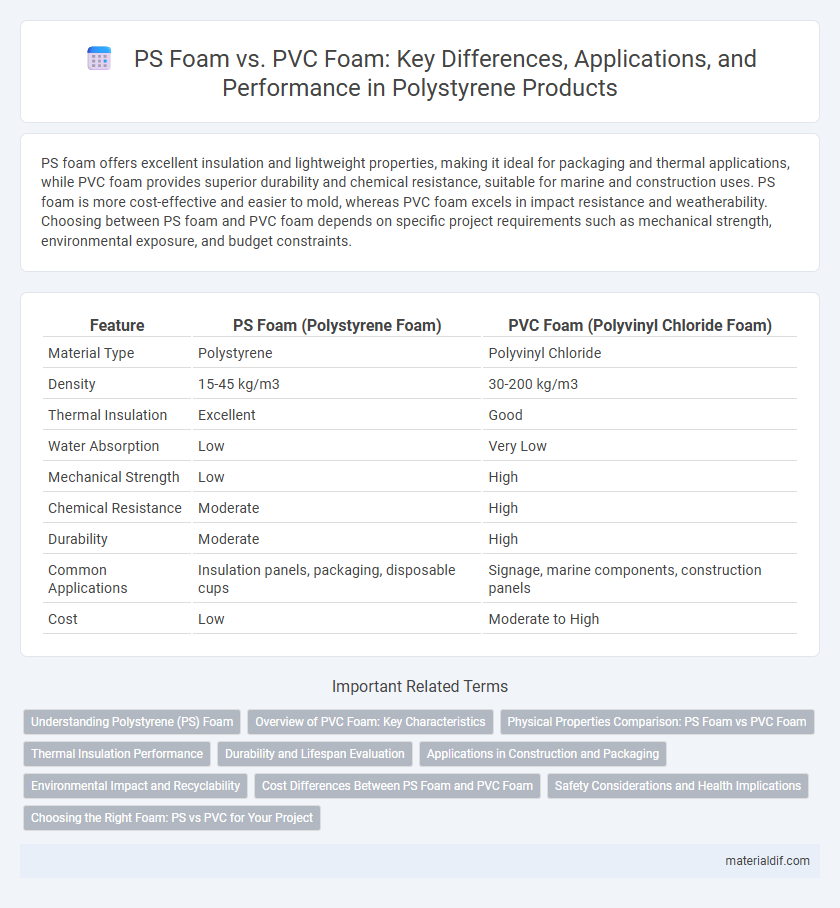

PS foam offers excellent insulation and lightweight properties, making it ideal for packaging and thermal applications, while PVC foam provides superior durability and chemical resistance, suitable for marine and construction uses. PS foam is more cost-effective and easier to mold, whereas PVC foam excels in impact resistance and weatherability. Choosing between PS foam and PVC foam depends on specific project requirements such as mechanical strength, environmental exposure, and budget constraints.

Table of Comparison

| Feature | PS Foam (Polystyrene Foam) | PVC Foam (Polyvinyl Chloride Foam) |

|---|---|---|

| Material Type | Polystyrene | Polyvinyl Chloride |

| Density | 15-45 kg/m3 | 30-200 kg/m3 |

| Thermal Insulation | Excellent | Good |

| Water Absorption | Low | Very Low |

| Mechanical Strength | Low | High |

| Chemical Resistance | Moderate | High |

| Durability | Moderate | High |

| Common Applications | Insulation panels, packaging, disposable cups | Signage, marine components, construction panels |

| Cost | Low | Moderate to High |

Understanding Polystyrene (PS) Foam

Polystyrene (PS) foam is a lightweight, rigid material known for its excellent thermal insulation and moisture resistance, making it ideal for packaging and insulation applications compared to PVC foam. Unlike PVC foam, which offers greater flexibility and chemical resistance, PS foam provides superior rigidity and ease of fabrication at a lower cost. Understanding these material properties helps in selecting the appropriate foam type based on specific requirements like durability, weight, and environmental exposure.

Overview of PVC Foam: Key Characteristics

PVC foam features a closed-cell structure that provides excellent rigidity, lightweight properties, and superior resistance to moisture and chemicals compared to PS foam. It offers enhanced durability and weather resistance, making it ideal for outdoor applications in construction and signage. The material also provides good thermal insulation and flame retardancy, distinguishing it from the more brittle and less chemically resistant PS foam.

Physical Properties Comparison: PS Foam vs PVC Foam

PS foam offers higher rigidity and superior thermal insulation compared to PVC foam, making it ideal for packaging and insulation applications. PVC foam exhibits greater impact resistance, flexibility, and chemical resistance, which suits it for automotive and construction uses. Density differences influence durability and load-bearing capacity, with PVC foam generally presenting a denser, tougher material than PS foam.

Thermal Insulation Performance

PS foam exhibits superior thermal insulation performance compared to PVC foam due to its lower thermal conductivity, typically around 0.03-0.04 W/m*K, which effectively reduces heat transfer. The closed-cell structure of polystyrene foam traps air, enhancing its insulating properties, making it ideal for building insulation and refrigeration applications. Conversely, PVC foam has higher thermal conductivity, generally above 0.05 W/m*K, resulting in less efficient thermal resistance.

Durability and Lifespan Evaluation

Polystyrene (PS) foam offers high rigidity and excellent impact resistance, but it tends to degrade faster under UV exposure compared to PVC foam, which provides superior weather resistance and longevity. PVC foam's closed-cell structure enhances its durability by resisting moisture absorption and chemical damage, resulting in a longer lifespan often exceeding 20 years in exterior applications. When evaluating durability and lifespan, PVC foam is generally preferred for outdoor and harsh environment uses, whereas PS foam performs well in indoor or controlled conditions.

Applications in Construction and Packaging

PS foam excels in insulation and lightweight packaging due to its thermal resistance and cushioning properties, commonly used in building insulation panels and protective packaging for electronics. PVC foam offers superior durability and chemical resistance, making it ideal for exterior cladding, roofing sheets, and rigid packaging solutions that require impact resistance and weatherability. Both materials serve vital roles in construction and packaging, with PS foam favored for thermal and shock absorption, whereas PVC foam is chosen for structural strength and longevity.

Environmental Impact and Recyclability

PS foam generates significant environmental challenges due to its non-biodegradability and limited recycling infrastructure, often ending up in landfills or oceans where it contributes to long-term pollution. PVC foam presents similar environmental concerns, with the added issue of releasing hazardous chemicals like dioxins during production and incineration, complicating safe disposal and recycling processes. Recycling rates for both materials remain low, emphasizing the need for improved recycling technologies and development of sustainable alternatives to minimize their ecological footprint.

Cost Differences Between PS Foam and PVC Foam

Polystyrene (PS) foam generally offers a lower cost compared to PVC foam due to its simpler manufacturing process and the use of less expensive raw materials. PVC foam is typically more expensive as it provides enhanced durability, chemical resistance, and higher impact strength, which increases production costs. Industries often choose PS foam for budget-sensitive applications, while PVC foam is preferred where performance justifies the higher price.

Safety Considerations and Health Implications

Polystyrene (PS) foam releases fewer toxic fumes compared to PVC foam, which emits harmful hydrogen chloride gas when burned, posing significant respiratory risks. PS foam is generally considered safer for indoor use due to its lower toxicity and reduced volatile organic compound (VOC) emissions. However, both materials are combustible and require careful handling to minimize fire hazards and potential health implications from smoke inhalation.

Choosing the Right Foam: PS vs PVC for Your Project

PS foam offers excellent thermal insulation and is lightweight, making it ideal for packaging and insulation projects, while PVC foam provides greater durability, chemical resistance, and structural strength suited for outdoor applications and signage. Consider the environment and load-bearing requirements: PS foam excels in cost-effectiveness and insulation, whereas PVC foam supports mechanical stress and weather exposure. Selecting between PS and PVC foam depends on balancing insulation needs, environmental exposure, and budget constraints for optimal project performance.

PS Foam vs PVC Foam Infographic

materialdif.com

materialdif.com