Polystyrene waste poses significant environmental challenges due to its persistence in ecosystems, making biodegradation a preferred solution for reducing its long-term impact. Biodegradation involves breaking down polystyrene into non-toxic components through microbial activity, offering a sustainable alternative to incineration, which releases harmful pollutants and greenhouse gases. Choosing biodegradation over incineration minimizes air pollution and helps promote eco-friendly waste management practices.

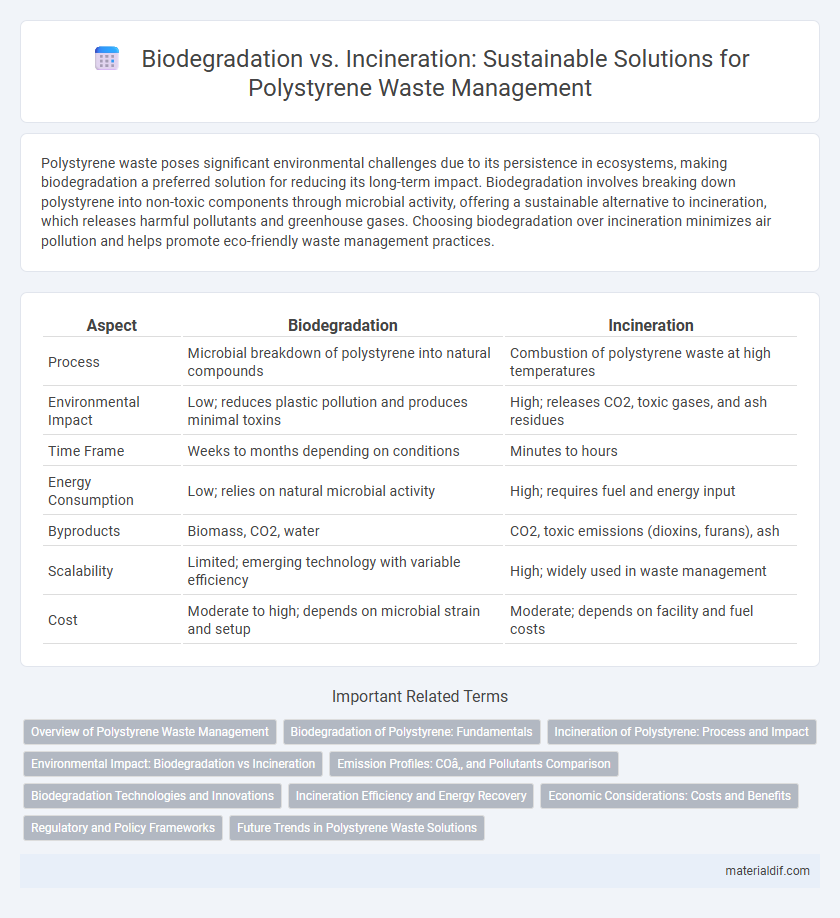

Table of Comparison

| Aspect | Biodegradation | Incineration |

|---|---|---|

| Process | Microbial breakdown of polystyrene into natural compounds | Combustion of polystyrene waste at high temperatures |

| Environmental Impact | Low; reduces plastic pollution and produces minimal toxins | High; releases CO2, toxic gases, and ash residues |

| Time Frame | Weeks to months depending on conditions | Minutes to hours |

| Energy Consumption | Low; relies on natural microbial activity | High; requires fuel and energy input |

| Byproducts | Biomass, CO2, water | CO2, toxic emissions (dioxins, furans), ash |

| Scalability | Limited; emerging technology with variable efficiency | High; widely used in waste management |

| Cost | Moderate to high; depends on microbial strain and setup | Moderate; depends on facility and fuel costs |

Overview of Polystyrene Waste Management

Polystyrene waste management primarily involves biodegradation and incineration methods, with biodegradation being significantly slower due to the polymer's chemical structure resisting microbial breakdown. Incineration offers rapid volume reduction and energy recovery but poses environmental concerns such as toxic emissions and greenhouse gas release. Effective waste management requires balancing biodegradation's environmental compatibility with incineration's efficiency while exploring advanced recycling and chemical depolymerization technologies.

Biodegradation of Polystyrene: Fundamentals

Biodegradation of polystyrene involves the breakdown of its long polymer chains by specific microorganisms, resulting in smaller, environmentally benign molecules such as carbon dioxide and water. This process is influenced by factors like microbial strain efficiency, environmental conditions including temperature and pH, and the presence of additives or pretreatments that enhance polymer susceptibility. Understanding enzymatic mechanisms and optimizing microbial consortia are key to improving biodegradation rates and developing sustainable waste management strategies.

Incineration of Polystyrene: Process and Impact

Incineration of polystyrene involves high-temperature combustion, reducing waste volume by up to 90% and converting the material into energy. This process emits pollutants such as styrene monomers, carbon monoxide, and dioxins, necessitating advanced filtration and emission control systems to minimize environmental harm. While incineration decreases landfill dependency, the release of toxic byproducts and greenhouse gases remains a critical environmental and health concern.

Environmental Impact: Biodegradation vs Incineration

Biodegradation of polystyrene waste significantly reduces long-term environmental pollution by breaking down the polymer into non-toxic components, minimizing soil and water contamination. Incineration, while reducing waste volume, releases harmful pollutants such as dioxins, furans, and greenhouse gases, contributing to air pollution and global warming. Biodegradation offers a sustainable waste management solution by promoting natural recycling processes, unlike incineration which poses serious ecological risks due to toxic emissions.

Emission Profiles: CO₂ and Pollutants Comparison

Polystyrene biodegradation emits negligible amounts of CO2 but occurs at an extremely slow rate, leading to prolonged environmental persistence. Incineration of polystyrene produces significant CO2 emissions alongside harmful pollutants such as dioxins, furans, and polycyclic aromatic hydrocarbons (PAHs). Comparative studies indicate incineration contributes substantially more to atmospheric pollution, whereas biodegradation, despite lower emissions, fails to mitigate waste volume effectively.

Biodegradation Technologies and Innovations

Biodegradation technologies for polystyrene waste have advanced through the use of specialized microbial strains, such as Pseudomonas and Rhodococcus species, capable of breaking down polystyrene's complex polymer chains into environmentally benign byproducts. Innovations include enzymatic treatments and bioaugmentation methods that enhance microbial efficiency, significantly reducing degradation time compared to natural processes. Research on integrating biodegradable additives during polystyrene production also shows promise in improving its subsequent biodegradability without compromising material performance.

Incineration Efficiency and Energy Recovery

Incineration of polystyrene waste achieves high energy recovery efficiency due to its elevated calorific value of approximately 40 MJ/kg, enabling effective conversion into thermal energy for power generation. Advanced incineration technologies, such as fluidized bed and rotary kiln systems, optimize combustion temperature and emissions control, reducing toxic byproducts like styrene monomers and volatile organic compounds (VOCs). While biodegradation of polystyrene is slow and limited, incineration offers a more viable waste-to-energy solution, minimizing landfill volume and harnessing substantial energy output from polystyrene's hydrocarbon-rich composition.

Economic Considerations: Costs and Benefits

Biodegradation of polystyrene offers potential cost savings by reducing landfill fees and minimizing environmental remediation expenses, though it may require significant investment in research and development to optimize microbial efficiency. Incineration provides immediate volume reduction and energy recovery benefits, but involves higher operational costs, emissions control, and potential health risks impacting long-term economic viability. Evaluating lifecycle costs reveals biodegradation can be more sustainable economically when scaled, while incineration demands ongoing expenditure for facility maintenance and pollution management.

Regulatory and Policy Frameworks

Regulatory frameworks increasingly emphasize the reduction of polystyrene waste through biodegradation-friendly policies, incentivizing the development of eco-friendly alternatives and compostable materials. Incineration regulations often impose strict emission standards to control the release of toxic compounds like styrene and dioxins during polystyrene combustion. Policies under organizations such as the EPA and EU directives promote a shift from incineration towards sustainable waste management practices, prioritizing environmental impact and public health.

Future Trends in Polystyrene Waste Solutions

Emerging trends in polystyrene waste management emphasize enhanced biodegradation through engineered microbial strains and enzymatic treatments targeting styrene polymer chains. Advanced incineration technologies incorporating energy recovery and emission control systems present a method for reducing environmental impact while generating electricity. Integration of circular economy principles promotes development of chemical recycling and bio-based polystyrene alternatives, accelerating transition to sustainable waste solutions.

Biodegradation vs Incineration (Polystyrene Waste) Infographic

materialdif.com

materialdif.com