PS foam, or polystyrene foam, is a versatile, lightweight material commonly used in packaging and insulation applications due to its excellent cushioning properties and durability. EPS foam, or expanded polystyrene foam, is a type of PS foam characterized by its expanded bead structure, providing superior thermal insulation and impact resistance while being more environmentally friendly due to its recyclability. Comparing PS foam and EPS foam reveals EPS's advantage in insulation performance and sustainability, making it a preferred choice for construction and food packaging industries.

Table of Comparison

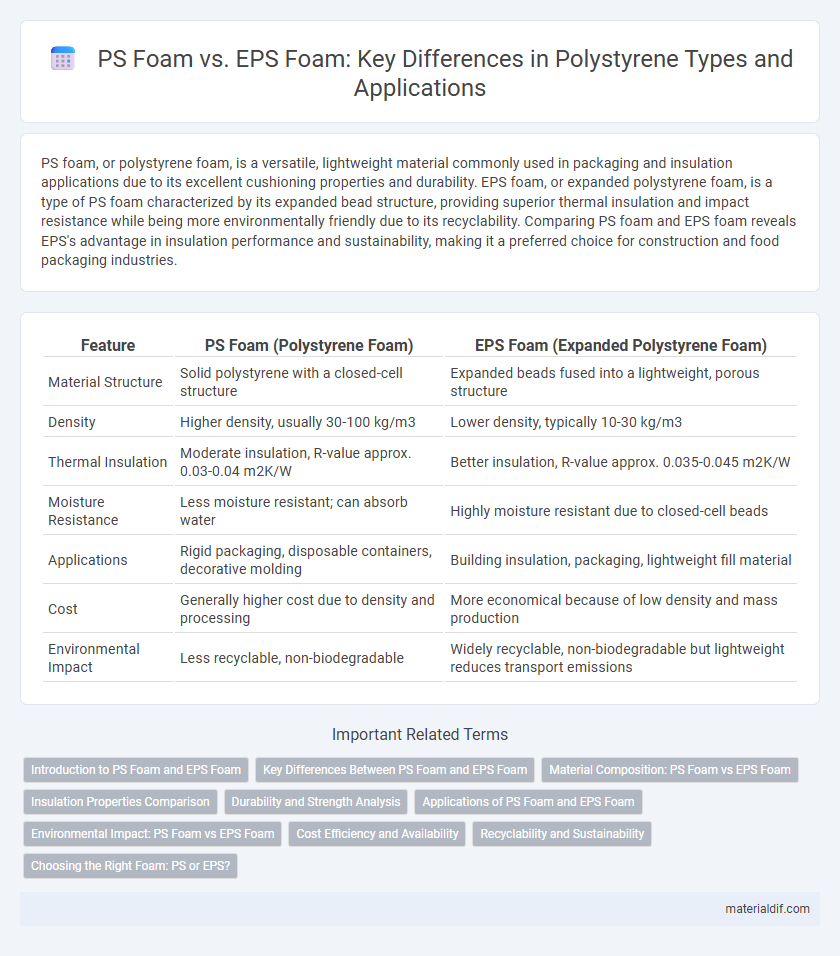

| Feature | PS Foam (Polystyrene Foam) | EPS Foam (Expanded Polystyrene Foam) |

|---|---|---|

| Material Structure | Solid polystyrene with a closed-cell structure | Expanded beads fused into a lightweight, porous structure |

| Density | Higher density, usually 30-100 kg/m3 | Lower density, typically 10-30 kg/m3 |

| Thermal Insulation | Moderate insulation, R-value approx. 0.03-0.04 m2K/W | Better insulation, R-value approx. 0.035-0.045 m2K/W |

| Moisture Resistance | Less moisture resistant; can absorb water | Highly moisture resistant due to closed-cell beads |

| Applications | Rigid packaging, disposable containers, decorative molding | Building insulation, packaging, lightweight fill material |

| Cost | Generally higher cost due to density and processing | More economical because of low density and mass production |

| Environmental Impact | Less recyclable, non-biodegradable | Widely recyclable, non-biodegradable but lightweight reduces transport emissions |

Introduction to PS Foam and EPS Foam

Polystyrene foam (PS Foam) is a versatile material widely used for insulation, packaging, and cushioning due to its lightweight and impact resistance properties. Expanded Polystyrene (EPS) Foam, a type of PS Foam, features a cellular structure created by expanding beads of polystyrene, offering excellent thermal insulation and moisture resistance. Both PS Foam and EPS Foam serve critical roles in construction and packaging industries, with EPS Foam being favored for energy-efficient building solutions.

Key Differences Between PS Foam and EPS Foam

PS foam, also known as expanded polystyrene (EPS), is a lightweight, rigid insulating material widely used in packaging and construction, but it is important to note that EPS foam specifically refers to the bead foam type manufactured by expanding polystyrene beads. Key differences between PS foam and EPS foam include density and chemical composition variations, where PS foam often refers to extruded polystyrene (XPS) with higher density, better moisture resistance, and increased compressive strength compared to the bead-based, lower-density EPS foam. Thermal insulation properties also differ, with XPS foam delivering higher R-values per inch, making it more suitable for applications requiring superior thermal performance.

Material Composition: PS Foam vs EPS Foam

PS foam, also known as general polystyrene foam, consists of solid polystyrene beads fused into a lightweight structure, offering moderate rigidity and thermal insulation. EPS foam, expanded polystyrene, is made by expanding polystyrene beads with gas, creating a foam with a closed-cell structure that provides superior insulation and cushioning properties. The main difference in material composition lies in EPS foam's higher air content within larger cells, resulting in enhanced shock absorption and thermal resistance compared to the more compact structure of PS foam.

Insulation Properties Comparison

Polystyrene foam (PS foam) and expanded polystyrene foam (EPS foam) both offer effective insulation but differ significantly in thermal performance. EPS foam features a lower thermal conductivity, typically around 0.03 W/m*K, making it superior for heat resistance compared to PS foam which ranges from 0.033 to 0.04 W/m*K. The closed-cell structure of EPS enhances its moisture resistance and compressive strength, contributing to better long-term insulation stability in architectural and packaging applications.

Durability and Strength Analysis

PS foam, known as expanded polystyrene (EPS), offers lightweight insulation but differs in density and structural integrity compared to extruded polystyrene (XPS) foam. EPS foam has a more open-cell structure, resulting in lower compressive strength and reduced durability under prolonged load and moisture exposure. XPS foam exhibits a closed-cell composition, providing enhanced durability, higher compressive strength up to 40 psi or more, and improved resistance to water absorption, making it ideal for demanding construction and insulation applications.

Applications of PS Foam and EPS Foam

PS foam, commonly used in packaging, insulation, and disposable food containers, offers lightweight cushioning and thermal resistance ideal for protecting fragile items and maintaining temperature. EPS foam excels in construction insulation, shipping materials, and recreational floatation devices due to its superior rigidity, moisture resistance, and energy absorption properties. Both foams serve essential roles in reducing product damage and enhancing energy efficiency across various industrial and consumer applications.

Environmental Impact: PS Foam vs EPS Foam

PS foam, commonly known as expanded polystyrene (EPS), and extruded polystyrene foam differ slightly in environmental impact due to their production processes and end-of-life options. EPS foam is more widely recycled and generally has a lower carbon footprint because of its lighter weight and less energy-intensive manufacturing compared to PS foam variants. Both foams are non-biodegradable, but EPS foam's recyclability makes it a relatively more sustainable choice in packaging and insulation applications.

Cost Efficiency and Availability

Polystyrene (PS) foam generally offers superior cost efficiency compared to expanded polystyrene (EPS) foam due to its higher density and better insulation properties, which reduce material usage and energy costs. EPS foam remains widely available and popular for packaging and insulation because of its lightweight nature and lower upfront cost, making it accessible for large-scale applications. Industrial applications often choose PS foam for long-term savings despite EPS foam's broader availability in the market.

Recyclability and Sustainability

PS foam and EPS foam differ significantly in recyclability and sustainability; EPS foam is more widely accepted in recycling programs due to its lower density and ease of processing, facilitating material recovery. Both materials pose environmental challenges, but EPS foam's closed-cell structure allows for efficient reuse in insulation and packaging products, enhancing its sustainability profile. Innovations in recycling technologies continue to improve the viability of PS foam reclamation, reducing landfill impact and supporting circular economy initiatives.

Choosing the Right Foam: PS or EPS?

Polystyrene (PS) foam and expanded polystyrene (EPS) foam differ primarily in manufacturing processes and structural properties, with PS foam being more rigid and smooth, ideal for packaging delicate items and insulating flat surfaces. EPS foam, characterized by its lightweight, resilient, and shock-absorbing qualities, excels in protective packaging, thermal insulation in buildings, and cushioning materials. Selecting the right foam depends on specific application requirements such as durability, insulation performance, and environmental impact, where EPS offers better thermal resistance and recyclability while PS foam provides superior surface finish and strength.

PS Foam vs EPS Foam Infographic

materialdif.com

materialdif.com