Bead Polystyrene consists of small, expandable beads that are fused together, offering excellent insulation and cushioning properties ideal for packaging and thermal insulation. Sheet Polystyrene, produced through extrusion or casting, provides rigid, flat panels commonly used in construction, signage, and crafts due to its structural strength and ease of fabrication. Choosing between bead and sheet forms depends on the application's need for flexibility, density, and durability.

Table of Comparison

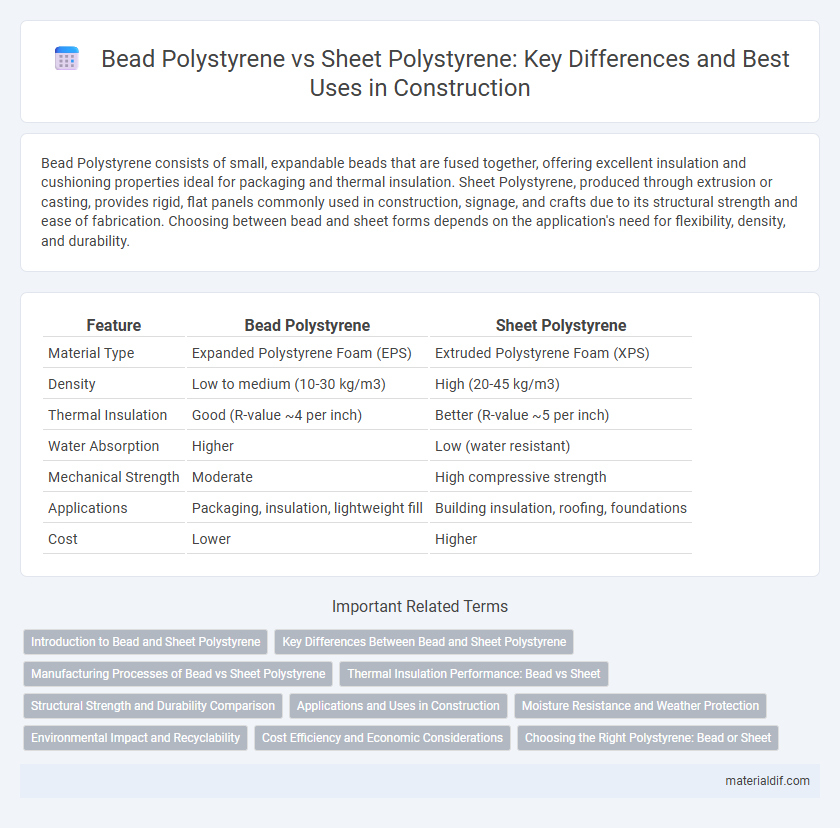

| Feature | Bead Polystyrene | Sheet Polystyrene |

|---|---|---|

| Material Type | Expanded Polystyrene Foam (EPS) | Extruded Polystyrene Foam (XPS) |

| Density | Low to medium (10-30 kg/m3) | High (20-45 kg/m3) |

| Thermal Insulation | Good (R-value ~4 per inch) | Better (R-value ~5 per inch) |

| Water Absorption | Higher | Low (water resistant) |

| Mechanical Strength | Moderate | High compressive strength |

| Applications | Packaging, insulation, lightweight fill | Building insulation, roofing, foundations |

| Cost | Lower | Higher |

Introduction to Bead and Sheet Polystyrene

Bead polystyrene consists of expandable beads that are molded into shapes through heat expansion, offering excellent insulation and lightweight properties ideal for packaging and thermal insulation. Sheet polystyrene, produced through extrusion or casting, provides a rigid, flat form used in construction, signage, and model-making due to its durability and structural stability. Both types derive from polystyrene polymer but differ significantly in form, fabrication process, and application versatility.

Key Differences Between Bead and Sheet Polystyrene

Bead polystyrene, also known as expanded polystyrene (EPS), is composed of small, lightweight beads fused together, offering excellent thermal insulation and shock absorption properties. Sheet polystyrene, typically extruded polystyrene (XPS), features a dense, rigid structure providing higher compressive strength, moisture resistance, and uniform thickness for construction and insulation applications. Key differences lie in their manufacturing processes, density, insulation efficiency, and suitability for specific uses such as packaging (bead polystyrene) versus structural insulation (sheet polystyrene).

Manufacturing Processes of Bead vs Sheet Polystyrene

Bead polystyrene is manufactured through a suspension polymerization process where small beads are formed by polymerizing styrene monomers in water, allowing for expansion into foam through heat and blowing agents. Sheet polystyrene is produced via extrusion or calendering, where molten polystyrene pellets are melted and formed into continuous sheets with controlled thickness and density. The bead process enables lightweight, insulating foam materials, while the sheet process provides rigid, smooth plastic sheets for fabrication and industrial applications.

Thermal Insulation Performance: Bead vs Sheet

Bead polystyrene, characterized by its expanded spherical beads, exhibits superior thermal insulation due to its higher air content and lower thermal conductivity, typically around 0.035 W/m*K, compared to sheet polystyrene, which ranges from 0.03 to 0.04 W/m*K depending on density. Sheet polystyrene offers more uniform structure and mechanical strength but generally has slightly lower insulating efficiency in standard applications. Thermal performance differences between bead and sheet polystyrene influence their optimal use in construction, with bead polystyrene preferred for loose-fill insulation and sheet polystyrene favored for rigid, load-bearing insulation panels.

Structural Strength and Durability Comparison

Bead polystyrene, characterized by its lightweight foam structure, offers excellent thermal insulation but lower structural strength and durability compared to sheet polystyrene. Sheet polystyrene, often denser and more rigid, provides superior load-bearing capacity and resistance to impact, making it ideal for applications requiring enhanced durability. The closed-cell structure of sheet polystyrene minimizes moisture absorption, significantly extending its lifespan in structural uses.

Applications and Uses in Construction

Bead polystyrene is widely used in construction for thermal insulation in walls, roofs, and floors due to its lightweight and excellent thermal resistance properties. Sheet polystyrene, including extruded (XPS) and expanded (EPS) types, is favored for rigid insulation panels in foundation walls, under slabs, and in roofing systems, providing structural support and moisture resistance. Both forms enhance energy efficiency and reduce heating and cooling costs, but bead polystyrene excels in fill applications, while sheet polystyrene is preferred for load-bearing insulation solutions.

Moisture Resistance and Weather Protection

Bead polystyrene, primarily used as expanded polystyrene (EPS), offers superior moisture resistance due to its closed-cell structure, making it ideal for insulation in damp environments. Sheet polystyrene, such as extruded polystyrene (XPS), provides enhanced weather protection with higher density and water resistance, suitable for exterior applications exposed to harsh conditions. Both forms contribute to effective thermal insulation, but sheet polystyrene outperforms bead polystyrene in long-term durability against weathering and moisture infiltration.

Environmental Impact and Recyclability

Bead polystyrene, commonly used as expanded polystyrene foam, has a high environmental impact due to its low density, difficulty in recycling, and tendency to fragment into microplastics, causing pollution and wildlife harm. Sheet polystyrene, or extruded polystyrene, offers improved recyclability through specialized processes, enabling its reuse in insulation products and reducing landfill waste. Both forms require efficient recycling infrastructure to mitigate their environmental footprint, but sheet polystyrene's structural integrity facilitates higher recovery rates compared to bead polystyrene.

Cost Efficiency and Economic Considerations

Bead polystyrene offers superior cost efficiency compared to sheet polystyrene due to its lightweight, expandable nature, which reduces transportation and installation expenses. Sheet polystyrene, while providing better structural integrity, generally incurs higher material and labor costs, making it less economical for large-scale insulation projects. Economic considerations favor bead polystyrene for applications requiring extensive coverage and budget-conscious solutions.

Choosing the Right Polystyrene: Bead or Sheet

Bead polystyrene offers excellent thermal insulation and lightweight properties, making it ideal for packaging and construction insulation. Sheet polystyrene provides superior rigidity and moisture resistance, suitable for signage, model making, and structural applications. Selecting between bead and sheet polystyrene depends on the specific requirements for durability, insulation, and form factor in your project.

Bead Polystyrene vs Sheet Polystyrene Infographic

materialdif.com

materialdif.com