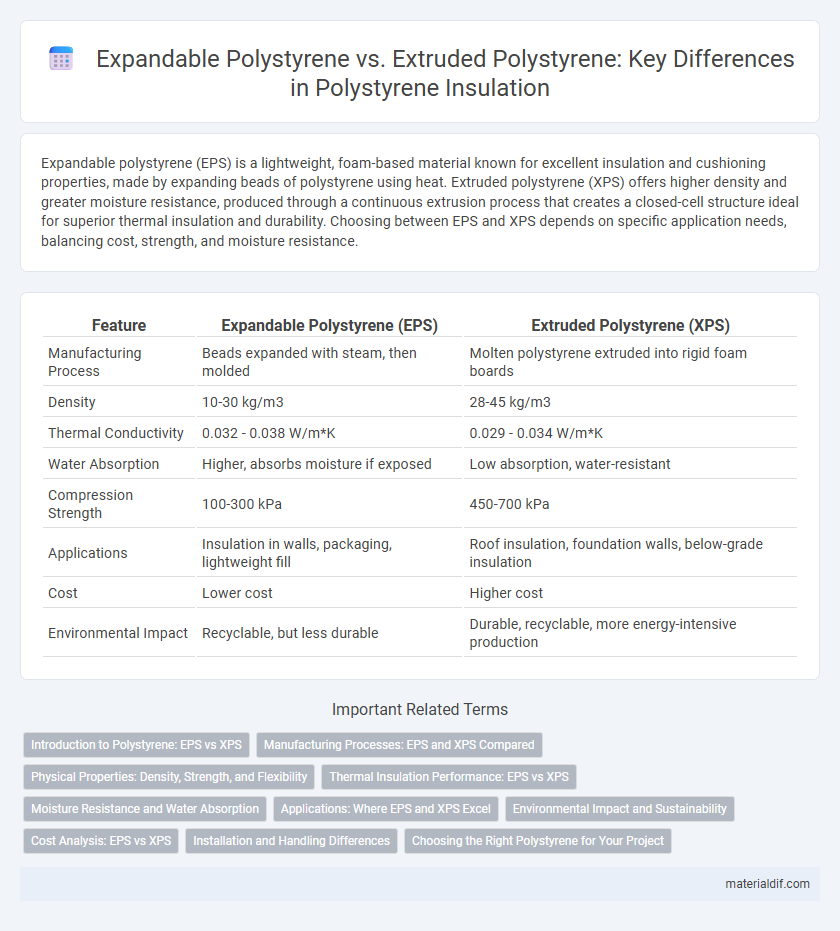

Expandable polystyrene (EPS) is a lightweight, foam-based material known for excellent insulation and cushioning properties, made by expanding beads of polystyrene using heat. Extruded polystyrene (XPS) offers higher density and greater moisture resistance, produced through a continuous extrusion process that creates a closed-cell structure ideal for superior thermal insulation and durability. Choosing between EPS and XPS depends on specific application needs, balancing cost, strength, and moisture resistance.

Table of Comparison

| Feature | Expandable Polystyrene (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Manufacturing Process | Beads expanded with steam, then molded | Molten polystyrene extruded into rigid foam boards |

| Density | 10-30 kg/m3 | 28-45 kg/m3 |

| Thermal Conductivity | 0.032 - 0.038 W/m*K | 0.029 - 0.034 W/m*K |

| Water Absorption | Higher, absorbs moisture if exposed | Low absorption, water-resistant |

| Compression Strength | 100-300 kPa | 450-700 kPa |

| Applications | Insulation in walls, packaging, lightweight fill | Roof insulation, foundation walls, below-grade insulation |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Recyclable, but less durable | Durable, recyclable, more energy-intensive production |

Introduction to Polystyrene: EPS vs XPS

Expandable polystyrene (EPS) consists of pre-expanded beads fused into rigid foam blocks, delivering excellent insulation properties with low water absorption, commonly used in packaging and thermal insulation. Extruded polystyrene (XPS) is produced through a continuous extrusion process resulting in a closed-cell structure, offering higher compressive strength, moisture resistance, and thermal efficiency than EPS, ideal for roofing and foundation insulation. Both EPS and XPS are lightweight, durable foam materials with polystyrene as the base polymer, but their distinct manufacturing methods and physical properties determine their suitability for specific insulation applications.

Manufacturing Processes: EPS and XPS Compared

Expandable polystyrene (EPS) is produced by pre-expanding polystyrene beads using steam, which causes them to expand and fuse within molds, resulting in a lightweight, porous material ideal for insulation and packaging. Extruded polystyrene (XPS) is manufactured through a continuous extrusion process where melted polystyrene is forced through a die and combined with blowing agents to create a closed-cell foam with consistent density and higher compressive strength. The key manufacturing difference lies in EPS's bead expansion versus XPS's extrusion, influencing their respective structural properties and applications.

Physical Properties: Density, Strength, and Flexibility

Expandable polystyrene (EPS) exhibits a lower density typically ranging from 10 to 30 kg/m3, offering lightweight insulation with moderate compressive strength and limited flexibility. Extruded polystyrene (XPS) has a higher density, approximately 28 to 45 kg/m3, resulting in superior compressive strength and enhanced durability under mechanical stress. XPS also demonstrates greater flexibility and moisture resistance compared to EPS, making it suitable for applications requiring structural stability and long-term performance.

Thermal Insulation Performance: EPS vs XPS

Expandable Polystyrene (EPS) offers good thermal insulation with an R-value typically ranging from 3.6 to 4.2 per inch, making it effective for general insulation purposes. Extruded Polystyrene (XPS) provides superior thermal performance, with R-values around 5 per inch, due to its closed-cell structure that reduces heat conduction and moisture absorption. The denser, more uniform composition of XPS results in better long-term thermal resistance and durability compared to EPS.

Moisture Resistance and Water Absorption

Expandable polystyrene (EPS) typically exhibits higher water absorption due to its open-cell structure, making it less moisture-resistant compared to extruded polystyrene (XPS), which has a closed-cell structure that significantly limits water penetration. XPS offers superior moisture resistance with water absorption rates often below 1%, whereas EPS can absorb up to 4-6% of its weight in water. This difference makes XPS the preferred choice for applications requiring enhanced durability in wet or humid environments.

Applications: Where EPS and XPS Excel

Expandable polystyrene (EPS) excels in packaging, insulation for walls, and lightweight fill for construction due to its excellent impact resistance and moisture permeability. Extruded polystyrene (XPS) performs best in applications requiring superior compressive strength and moisture resistance, such as below-grade insulation, roofing, and high-load floor systems. Both materials provide thermal insulation but are chosen based on the specific environmental demands and mechanical stresses of the project.

Environmental Impact and Sustainability

Expandable polystyrene (EPS) is lightweight and recyclable, but its production involves the use of hydrocarbon blowing agents contributing to greenhouse gas emissions. Extruded polystyrene (XPS) features higher thermal insulation and moisture resistance, yet typically relies on HFC blowing agents with a greater global warming potential, raising sustainability concerns. Both materials pose challenges for biodegradability, prompting ongoing development of eco-friendlier alternatives and improved recycling technologies to reduce environmental impact.

Cost Analysis: EPS vs XPS

Expandable polystyrene (EPS) generally offers a lower cost per cubic foot compared to extruded polystyrene (XPS), making it a more budget-friendly option for insulation projects. EPS is manufactured through a bead expansion process, which results in a lighter, more porous material, contributing to its affordability. In contrast, XPS production involves a more complex extrusion process yielding a denser, higher-performance foam with improved moisture resistance, but this elevated manufacturing cost is reflected in its higher market price.

Installation and Handling Differences

Expandable polystyrene (EPS) is lightweight, easy to cut, and allows for flexible installation in irregular shapes, making it ideal for custom applications; however, it may require protective coatings to enhance durability. Extruded polystyrene (XPS) has a rigid, closed-cell structure that provides higher compressive strength and moisture resistance, facilitating straightforward handling and installation in load-bearing and high-moisture environments. While EPS can compress slightly during installation, XPS maintains its shape under pressure, ensuring consistent thermal insulation performance over time.

Choosing the Right Polystyrene for Your Project

Expandable polystyrene (EPS) offers excellent thermal insulation with lightweight, rigid foam beads ideal for packaging and construction void filling, while extruded polystyrene (XPS) provides superior moisture resistance and consistent closed-cell structure, making it optimal for below-grade insulation and roofing applications. Factors like compressive strength, moisture exposure, and installation environment should guide the choice between EPS and XPS to ensure durability and energy efficiency. Selecting the right polystyrene depends on application-specific requirements such as thermal conductivity (R-value), density, and environmental conditions.

Expandable polystyrene vs Extruded polystyrene Infographic

materialdif.com

materialdif.com