Polystyrene offers excellent clarity and rigidity, making it ideal for lightweight packaging and disposable containers, while ABS plastic provides superior impact resistance and toughness for durable applications. Polystyrene is more cost-effective and easier to mold, but ABS plastic withstands higher temperatures and mechanical stress, suitable for automotive parts and electronics. Choosing between polystyrene and ABS depends on the balance between cost, strength, and application-specific requirements.

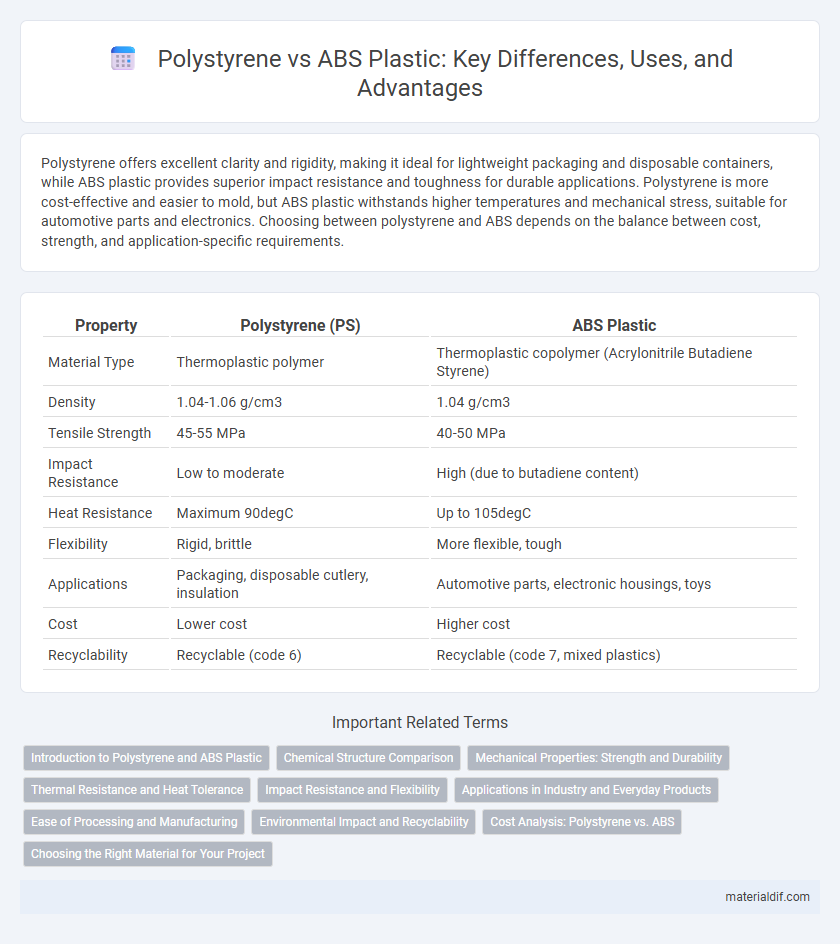

Table of Comparison

| Property | Polystyrene (PS) | ABS Plastic |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic copolymer (Acrylonitrile Butadiene Styrene) |

| Density | 1.04-1.06 g/cm3 | 1.04 g/cm3 |

| Tensile Strength | 45-55 MPa | 40-50 MPa |

| Impact Resistance | Low to moderate | High (due to butadiene content) |

| Heat Resistance | Maximum 90degC | Up to 105degC |

| Flexibility | Rigid, brittle | More flexible, tough |

| Applications | Packaging, disposable cutlery, insulation | Automotive parts, electronic housings, toys |

| Cost | Lower cost | Higher cost |

| Recyclability | Recyclable (code 6) | Recyclable (code 7, mixed plastics) |

Introduction to Polystyrene and ABS Plastic

Polystyrene is a versatile thermoplastic polymer known for its rigidity, clarity, and ease of molding, commonly used in packaging, insulation, and disposable cutlery. ABS plastic, or Acrylonitrile Butadiene Styrene, combines strength, impact resistance, and toughness, making it ideal for automotive parts, consumer electronics, and LEGO bricks. Both materials serve distinct industrial applications due to their unique mechanical and thermal properties.

Chemical Structure Comparison

Polystyrene (PS) is a polymer composed of repeating styrene monomers, featuring a benzene ring attached to a vinyl backbone, resulting in a rigid, thermoplastic structure. Acrylonitrile Butadiene Styrene (ABS) consists of three monomeric units: acrylonitrile, butadiene, and styrene, which combine to form a copolymer with enhanced toughness and impact resistance due to the rubbery butadiene phase dispersed in the styrene-acrylonitrile matrix. The chemical structure of PS provides higher rigidity and clarity, whereas the ABS structure balances rigidity with resilience, making ABS more suitable for applications requiring durability.

Mechanical Properties: Strength and Durability

Polystyrene offers moderate tensile strength and rigidity but is more brittle and less impact-resistant than ABS plastic, which provides superior toughness and flexibility. ABS excels in durability due to its enhanced impact resistance and higher resistance to physical stresses, making it suitable for applications requiring robust mechanical performance. Polystyrene, while lighter and easier to mold, lacks the mechanical resilience that makes ABS a preferred choice in automotive parts and protective gear.

Thermal Resistance and Heat Tolerance

Polystyrene exhibits lower thermal resistance compared to ABS plastic, with a glass transition temperature around 95degC versus ABS's approximately 105degC. ABS plastic tolerates higher heat exposure and maintains structural integrity under elevated temperatures, making it suitable for applications requiring enhanced heat resistance. Polystyrene's reduced heat tolerance limits its use in environments with sustained high temperatures or thermal stress.

Impact Resistance and Flexibility

Polystyrene offers lower impact resistance compared to ABS plastic, making it more prone to cracking under stress. ABS plastic exhibits superior flexibility and toughness, allowing it to absorb shocks and resist fractures more effectively. This makes ABS the preferred choice for applications requiring durability and resilience against physical impact.

Applications in Industry and Everyday Products

Polystyrene is widely used in packaging, disposable cutlery, and insulation due to its rigidity and clarity, while ABS plastic excels in automotive parts, electronic housings, and LEGO bricks thanks to its impact resistance and toughness. In the electronics industry, ABS is preferred for durable casings, whereas polystyrene finds applications in lightweight, cost-effective containers and trays. Polystyrene's ease of molding and cost-efficiency make it ideal for disposable or decorative items, contrasting with ABS's suitability for structural and impact-bearing components.

Ease of Processing and Manufacturing

Polystyrene offers simpler processing due to its lower melting point and ability to be easily molded via injection molding and extrusion, making it ideal for high-volume production with minimal cycle times. In contrast, ABS plastic requires higher processing temperatures and more precise control during manufacturing to prevent warping and achieve optimal properties. Manufacturers favor polystyrene for applications needing rapid, cost-effective production, while ABS is chosen when impact resistance and durability outweigh ease of processing.

Environmental Impact and Recyclability

Polystyrene, primarily used in packaging and insulation, poses significant environmental challenges due to its low biodegradability and difficulty in recycling compared to ABS plastic, which is more durable and has higher recyclability rates. ABS plastic's robust molecular structure allows for easier mechanical recycling and repurposing, reducing its environmental footprint relative to polystyrene's widespread pollution issues and landfill persistence. Efforts to improve polystyrene recycling include chemical recycling methods and expanded collection programs to mitigate its ecological impact.

Cost Analysis: Polystyrene vs. ABS

Polystyrene generally offers a lower production cost compared to ABS plastic due to its simpler polymer structure and easier processing methods. ABS, while more expensive, provides enhanced impact resistance and durability, justifying its higher price in applications requiring toughness. Cost analysis reveals polystyrene suits budget-sensitive projects, whereas ABS is preferred when performance outweighs expenses.

Choosing the Right Material for Your Project

Polystyrene offers excellent clarity, rigidity, and ease of fabrication, making it ideal for lightweight applications like packaging and disposable containers. ABS plastic provides superior impact resistance, toughness, and heat resistance, suitable for durable products such as automotive parts and consumer electronics. Selecting between polystyrene and ABS depends on project requirements for strength, durability, and environmental exposure.

Polystyrene vs ABS Plastic Infographic

materialdif.com

materialdif.com