Crystal Polystyrene offers superior clarity and gloss compared to standard polystyrene, making it ideal for applications requiring high transparency and aesthetic appeal. Its enhanced optical properties result from a more refined polymer structure, which reduces haze and improves light transmission. Standard polystyrene, while cost-effective and versatile, typically lacks the crystal-clear finish that distinguishes crystal polystyrene in premium packaging and display products.

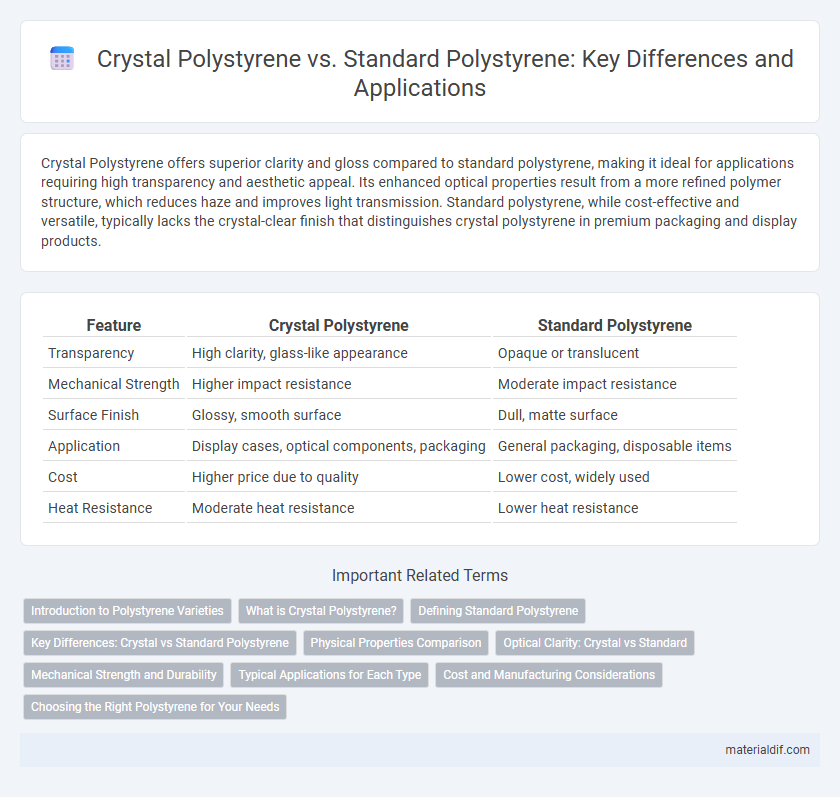

Table of Comparison

| Feature | Crystal Polystyrene | Standard Polystyrene |

|---|---|---|

| Transparency | High clarity, glass-like appearance | Opaque or translucent |

| Mechanical Strength | Higher impact resistance | Moderate impact resistance |

| Surface Finish | Glossy, smooth surface | Dull, matte surface |

| Application | Display cases, optical components, packaging | General packaging, disposable items |

| Cost | Higher price due to quality | Lower cost, widely used |

| Heat Resistance | Moderate heat resistance | Lower heat resistance |

Introduction to Polystyrene Varieties

Crystal polystyrene, known for its high transparency and rigidity, differs from standard polystyrene by offering superior optical clarity and enhanced mechanical strength. Standard polystyrene typically exhibits a more opaque appearance with greater flexibility, making it suitable for general-purpose applications. These distinct properties influence their use in industries such as packaging, consumer goods, and medical equipment, where either clarity or durability is prioritized.

What is Crystal Polystyrene?

Crystal Polystyrene, a transparent variant of standard polystyrene, features enhanced clarity and high gloss, making it ideal for applications requiring visual appeal such as display cases and packaging. Unlike standard polystyrene, which is typically opaque or frosted, crystal polystyrene offers superior light transmission and a smooth surface finish. Its chemical structure allows for greater rigidity and impact resistance while maintaining the lightweight characteristics common to polystyrene materials.

Defining Standard Polystyrene

Standard polystyrene is a versatile thermoplastic polymer characterized by its amorphous structure, providing good clarity and rigidity but limited impact resistance compared to its crystal counterpart. It is widely used in packaging, disposable cutlery, and insulation due to its low cost and ease of processing. Unlike crystal polystyrene, which has enhanced clarity and higher tensile strength, standard polystyrene offers balanced mechanical properties suitable for general-purpose applications.

Key Differences: Crystal vs Standard Polystyrene

Crystal polystyrene offers higher clarity and optical transparency compared to standard polystyrene, making it ideal for applications like display cases and food packaging where visual appeal is essential. Standard polystyrene exhibits greater impact resistance and is often used in disposable cutlery, insulation, and packaging materials where durability is prioritized over transparency. The molecular structure in crystal polystyrene is more uniform, resulting in its enhanced clarity, whereas standard polystyrene contains more amorphous regions contributing to its tougher, but less clear, nature.

Physical Properties Comparison

Crystal polystyrene exhibits higher transparency and better surface gloss compared to standard polystyrene, making it ideal for applications requiring visual appeal. Its tensile strength and stiffness are slightly enhanced, providing improved dimensional stability without compromising impact resistance. Standard polystyrene typically offers greater impact resistance and cost efficiency, making it suitable for general-purpose uses where optical clarity is less critical.

Optical Clarity: Crystal vs Standard

Crystal polystyrene offers superior optical clarity compared to standard polystyrene, exhibiting higher light transmittance and reduced haze levels, making it ideal for applications requiring transparent and visually appealing materials. The molecular structure of crystal polystyrene minimizes light scattering, resulting in a clearer and more transparent finished product. Standard polystyrene, while cost-effective, demonstrates lower clarity and increased opacity, limiting its use in aesthetic-sensitive applications.

Mechanical Strength and Durability

Crystal Polystyrene exhibits superior mechanical strength and enhanced durability compared to standard Polystyrene, making it more resistant to impact and deformation. Its molecular structure provides higher tensile strength and improved resistance to wear and tear under mechanical stress. These properties make Crystal Polystyrene ideal for applications requiring long-lasting performance and structural integrity.

Typical Applications for Each Type

Crystal polystyrene is commonly used in applications requiring high transparency and rigidity, such as clear packaging, display cases, and optical components. Standard polystyrene, with its more opaque and durable properties, is typically employed in disposable cutlery, insulation panels, and model making. The choice between these types depends on the need for clarity versus impact resistance in the end-use product.

Cost and Manufacturing Considerations

Crystal Polystyrene offers a higher clarity and gloss compared to Standard Polystyrene, which often results in increased manufacturing costs due to more stringent production controls and slower processing speeds. Standard Polystyrene typically provides a more cost-effective solution for mass production, with faster cycle times and less precise material handling requirements. Choosing between Crystal and Standard Polystyrene depends on balancing product aesthetics with budget constraints and manufacturing efficiency.

Choosing the Right Polystyrene for Your Needs

Crystal polystyrene offers superior transparency and rigidity compared to standard polystyrene, making it ideal for applications requiring clear, high-gloss finishes such as display cases and food packaging. Standard polystyrene is more cost-effective and versatile, suitable for general-purpose use like disposable cutlery and insulation materials. Evaluating factors like clarity, strength, and budget helps determine the optimal polystyrene type to match specific project requirements.

Crystal Polystyrene vs Standard Polystyrene Infographic

materialdif.com

materialdif.com