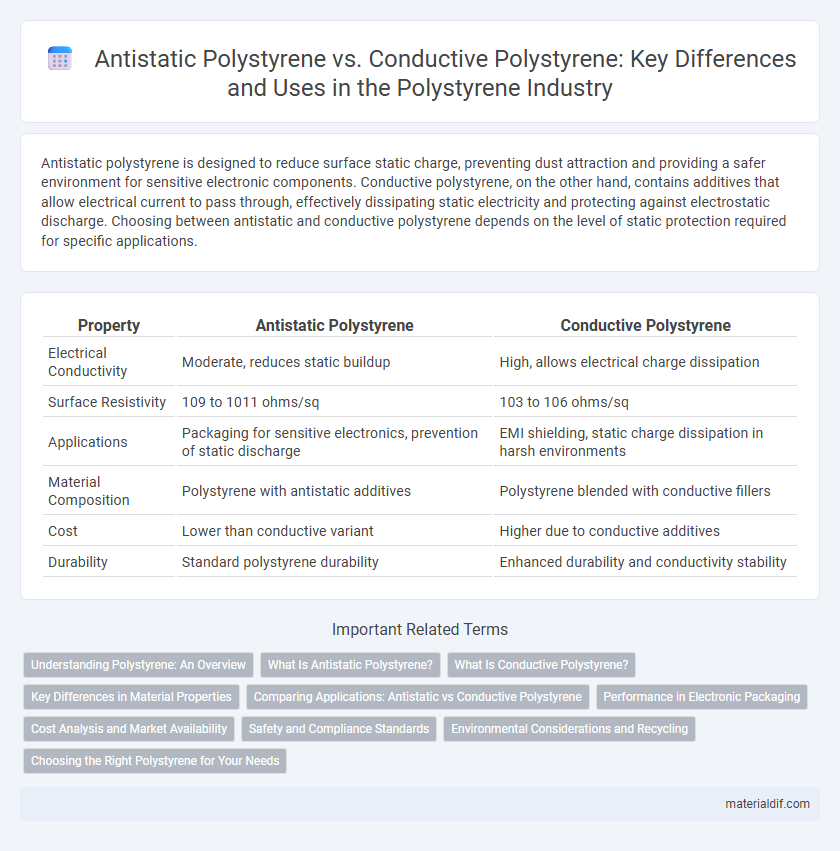

Antistatic polystyrene is designed to reduce surface static charge, preventing dust attraction and providing a safer environment for sensitive electronic components. Conductive polystyrene, on the other hand, contains additives that allow electrical current to pass through, effectively dissipating static electricity and protecting against electrostatic discharge. Choosing between antistatic and conductive polystyrene depends on the level of static protection required for specific applications.

Table of Comparison

| Property | Antistatic Polystyrene | Conductive Polystyrene |

|---|---|---|

| Electrical Conductivity | Moderate, reduces static buildup | High, allows electrical charge dissipation |

| Surface Resistivity | 109 to 1011 ohms/sq | 103 to 106 ohms/sq |

| Applications | Packaging for sensitive electronics, prevention of static discharge | EMI shielding, static charge dissipation in harsh environments |

| Material Composition | Polystyrene with antistatic additives | Polystyrene blended with conductive fillers |

| Cost | Lower than conductive variant | Higher due to conductive additives |

| Durability | Standard polystyrene durability | Enhanced durability and conductivity stability |

Understanding Polystyrene: An Overview

Antistatic polystyrene is designed to reduce static electricity buildup by incorporating additives that dissipate charges on the surface, making it ideal for packaging electronic components. Conductive polystyrene, on the other hand, achieves electrical conductivity through the integration of conductive fillers such as carbon black or metal particles, enabling it to conduct electricity throughout the material. Understanding these fundamental differences helps in selecting the appropriate polystyrene type for applications requiring either static control or electrical conduction.

What Is Antistatic Polystyrene?

Antistatic polystyrene is a modified version of polystyrene designed to reduce static electricity buildup on its surface by incorporating antistatic agents that increase surface conductivity without making the material fully conductive. This type of polystyrene is commonly used in packaging and electronic applications where protection against static discharge is critical, but electrical conductivity must remain low. Unlike conductive polystyrene, which allows electricity to flow freely, antistatic polystyrene provides a controlled dissipation of static charges to prevent damage or interference.

What Is Conductive Polystyrene?

Conductive polystyrene is a modified form of polystyrene infused with conductive fillers such as carbon black or metal powders to allow electrical conductivity. Unlike antistatic polystyrene, which primarily reduces static buildup on surfaces, conductive polystyrene creates a continuous path for electrical charge dissipation. This makes conductive polystyrene ideal for applications requiring electromagnetic interference (EMI) shielding and electrostatic discharge (ESD) protection in electronic packaging.

Key Differences in Material Properties

Antistatic polystyrene is designed to dissipate static electricity by allowing a controlled flow of electric charge on its surface, preventing dust attraction and static discharge without being fully conductive. Conductive polystyrene contains higher conductive fillers or additives, enabling it to conduct electricity through its bulk, essential for applications requiring rapid charge dissipation and electromagnetic interference shielding. Key differences lie in their electrical resistivity, with antistatic polystyrene having surface resistivity typically in the range of 10^9 to 10^12 ohms/sq, while conductive polystyrene exhibits much lower resistivity, often below 10^6 ohms/sq.

Comparing Applications: Antistatic vs Conductive Polystyrene

Antistatic polystyrene is commonly used in electronic packaging and components where preventing static charge buildup is crucial to avoid damage to sensitive devices. Conductive polystyrene finds applications in electromagnetic interference (EMI) shielding and grounding solutions due to its ability to conduct electricity efficiently. While antistatic polystyrene primarily prevents electrostatic discharge, conductive polystyrene is designed for direct electrical conductivity in electronic and industrial applications.

Performance in Electronic Packaging

Antistatic polystyrene reduces static charge build-up with surface resistivity typically between 10^9 and 10^11 ohms/sq, providing moderate protection against electrostatic discharge in electronic packaging. Conductive polystyrene offers lower surface resistivity, often below 10^6 ohms/sq, enabling efficient dissipation of static electricity and superior shielding performance for sensitive electronic components. The choice depends on required electrostatic discharge protection levels, with conductive grades preferred for high-risk environments due to their enhanced conductivity and reliability.

Cost Analysis and Market Availability

Antistatic polystyrene typically costs less than conductive polystyrene due to simpler manufacturing processes and lower material expenses, making it more accessible for general packaging and electronic housing. Conductive polystyrene involves conductive fillers like carbon or metal particles, significantly increasing production costs and limiting its availability to specialized markets such as sensitive electronic components and ESD protection. Market availability for antistatic polystyrene is broader with multiple suppliers and standard grades, while conductive polystyrene is more niche, often requiring custom orders and longer lead times.

Safety and Compliance Standards

Antistatic polystyrene reduces surface static electricity to prevent dust attraction and minimize electrostatic discharge without conducting electricity, aligning with safety standards such as IEC 61340-5-1 for electrostatic control. Conductive polystyrene, designed to safely dissipate static charges by allowing low electrical conductivity, must comply with stricter regulations including UL 94 for flammability and OSHA guidelines to ensure user protection in sensitive environments. Both materials meet industry-specific compliance requirements for electronics manufacturing, but conductive polystyrene is preferred where rapid charge dissipation is critical for safety and equipment reliability.

Environmental Considerations and Recycling

Antistatic polystyrene contains additives that minimize static charge buildup without significantly altering the base polymer's recyclability, making it easier to process in conventional recycling streams compared to conductive polystyrene. Conductive polystyrene incorporates conductive fillers like carbon black or metal particles, which can hinder recycling due to contamination and challenges in separating the materials, often resulting in downcycling or disposal. Environmental considerations favor antistatic variants for applications where static control is needed but sustainability and circular economy principles are prioritized.

Choosing the Right Polystyrene for Your Needs

Antistatic polystyrene contains additives that reduce static electricity buildup, making it ideal for packaging sensitive electronic components where static discharge can cause damage. Conductive polystyrene, on the other hand, possesses inherently high electrical conductivity, suitable for applications requiring effective grounding and rapid charge dissipation. Choosing the right polystyrene depends on the required level of electrical resistance and the specific environmental conditions of your project.

Antistatic Polystyrene vs Conductive Polystyrene Infographic

materialdif.com

materialdif.com