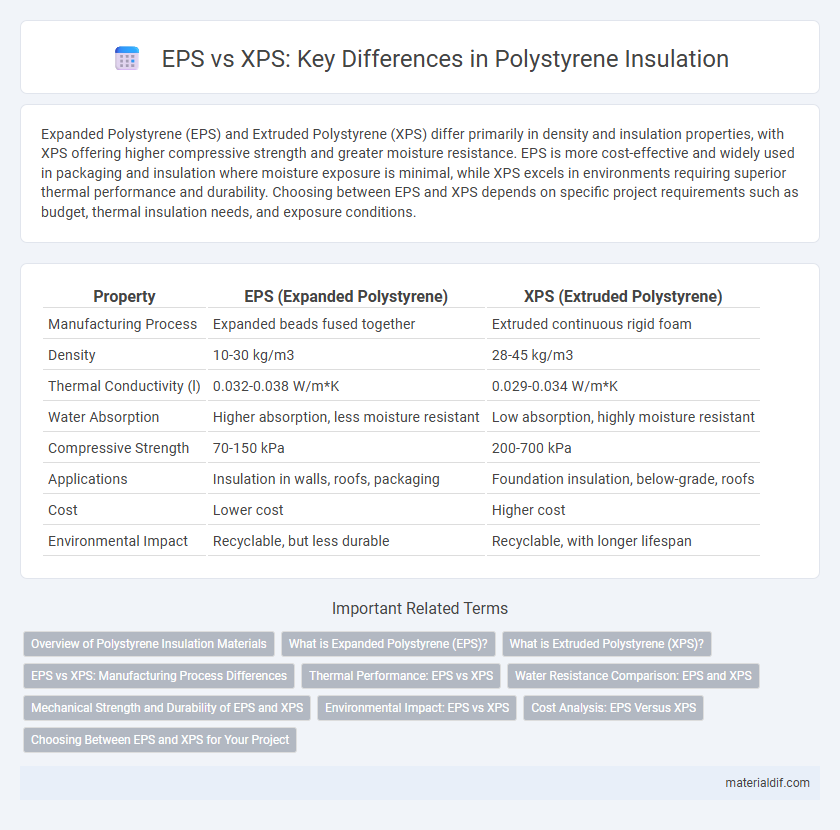

Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) differ primarily in density and insulation properties, with XPS offering higher compressive strength and greater moisture resistance. EPS is more cost-effective and widely used in packaging and insulation where moisture exposure is minimal, while XPS excels in environments requiring superior thermal performance and durability. Choosing between EPS and XPS depends on specific project requirements such as budget, thermal insulation needs, and exposure conditions.

Table of Comparison

| Property | EPS (Expanded Polystyrene) | XPS (Extruded Polystyrene) |

|---|---|---|

| Manufacturing Process | Expanded beads fused together | Extruded continuous rigid foam |

| Density | 10-30 kg/m3 | 28-45 kg/m3 |

| Thermal Conductivity (l) | 0.032-0.038 W/m*K | 0.029-0.034 W/m*K |

| Water Absorption | Higher absorption, less moisture resistant | Low absorption, highly moisture resistant |

| Compressive Strength | 70-150 kPa | 200-700 kPa |

| Applications | Insulation in walls, roofs, packaging | Foundation insulation, below-grade, roofs |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Recyclable, but less durable | Recyclable, with longer lifespan |

Overview of Polystyrene Insulation Materials

Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are two primary types of polystyrene insulation materials widely used in construction for thermal resistance. EPS is a lightweight, rigid foam composed of pre-expanded beads, offering high vapor permeability and cost-effective insulation with moderate compressive strength, making it suitable for wall cavities and under-slab insulation. XPS is produced through an extrusion process, resulting in a closed-cell structure with superior moisture resistance, higher compressive strength, and enhanced durability, ideal for below-grade and exterior applications where exposure to moisture and mechanical stress is significant.

What is Expanded Polystyrene (EPS)?

Expanded Polystyrene (EPS) is a lightweight, rigid foam material composed of pre-expanded polystyrene beads fused together, widely used for insulation and packaging. Its cellular structure provides excellent thermal insulation and shock absorption, making EPS an energy-efficient and cost-effective solution in construction and manufacturing. EPS differs from Extruded Polystyrene (XPS) by having a more open cell structure, which results in different moisture resistance and compressive strength properties.

What is Extruded Polystyrene (XPS)?

Extruded Polystyrene (XPS) is a dense, closed-cell foam insulation material produced through a continuous extrusion process, resulting in superior moisture resistance and higher compressive strength compared to Expanded Polystyrene (EPS). XPS is commonly used in roofing, foundation, and wall insulation applications where enhanced durability and thermal performance are required. Its consistent cell structure and resistance to water absorption make it ideal for environments exposed to moisture and pressure.

EPS vs XPS: Manufacturing Process Differences

Expanded Polystyrene (EPS) is produced by expanding pre-bead polystyrene using steam, resulting in a lightweight, open-cell foam with lower density and higher permeability. Extruded Polystyrene (XPS) manufacturing involves melting polystyrene pellets and extruding them through a die, creating a closed-cell, denser structure with enhanced moisture resistance and compressive strength. These distinct manufacturing processes directly influence the physical properties and performance applications of EPS and XPS insulation materials.

Thermal Performance: EPS vs XPS

Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) differ significantly in thermal performance, with XPS generally offering higher R-values per inch, typically around 5.0 compared to EPS's 3.6 to 4.2. This superior insulation capability of XPS stems from its closed-cell structure, which reduces water absorption and enhances thermal resistance. EPS, while less thermally efficient, provides better breathability and can be more cost-effective for certain applications.

Water Resistance Comparison: EPS and XPS

Extruded Polystyrene (XPS) exhibits significantly higher water resistance than Expanded Polystyrene (EPS), with XPS absorbing less than 1% of its volume in water under typical exposure conditions, compared to EPS which can absorb between 2% to 4%. This superior water resistance of XPS is due to its closed-cell structure, making it ideal for applications in soil or high-moisture environments where moisture retention may compromise thermal performance. EPS's higher water absorption rates can lead to decreased insulation efficiency, making XPS the preferred choice for long-term exposure to water or damp conditions.

Mechanical Strength and Durability of EPS and XPS

Expanded Polystyrene (EPS) offers good compressive strength and impact resistance, making it suitable for lightweight applications with moderate mechanical demands. Extruded Polystyrene (XPS) provides higher mechanical strength, superior rigidity, and enhanced durability under long-term load conditions, due to its closed-cell structure. XPS outperforms EPS in resisting moisture absorption and maintaining structural integrity in harsh environments, which contributes to its extended lifespan in construction and insulation uses.

Environmental Impact: EPS vs XPS

Expanded Polystyrene (EPS) has a lower environmental impact than Extruded Polystyrene (XPS) due to its higher recyclability and lower greenhouse gas emissions during production. EPS is typically made from beads fused together without chemical blowing agents, resulting in fewer toxic byproducts compared to XPS, which often uses Hydrofluorocarbons (HFCs) as blowing agents. While both materials are non-biodegradable, EPS's lighter density and widespread recycling infrastructure contribute to reduced landfill volume and environmental footprint.

Cost Analysis: EPS Versus XPS

Expanded Polystyrene (EPS) generally offers a lower initial cost compared to Extruded Polystyrene (XPS), making it a budget-friendly option for insulation projects. While XPS delivers superior moisture resistance and higher R-values per inch, its higher price can increase the overall project budget. Assessing long-term benefits, including energy savings and durability, is crucial when comparing the cost-effectiveness of EPS versus XPS insulation materials.

Choosing Between EPS and XPS for Your Project

Expanded Polystyrene (EPS) offers superior breathability and cost-efficiency, making it ideal for applications needing moisture permeability and budget-friendly insulation. Extruded Polystyrene (XPS) provides higher compressive strength and water resistance, suited for projects demanding durability and enhanced thermal performance. Evaluating project-specific requirements like exposure to moisture, load-bearing needs, and budget constraints is essential when choosing between EPS and XPS insulation materials.

EPS vs XPS Infographic

materialdif.com

materialdif.com