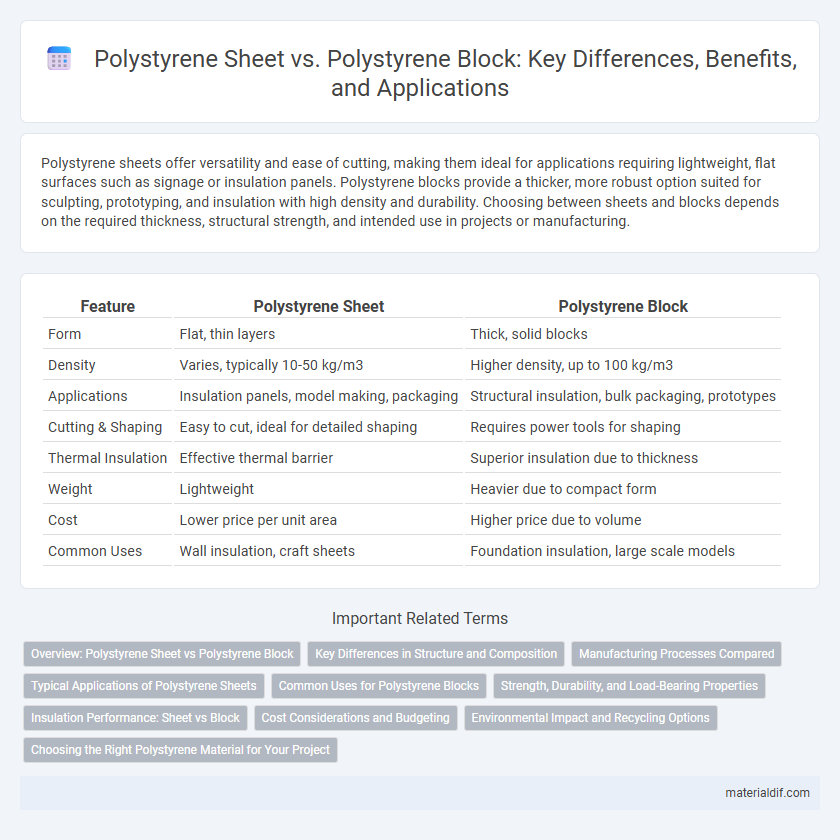

Polystyrene sheets offer versatility and ease of cutting, making them ideal for applications requiring lightweight, flat surfaces such as signage or insulation panels. Polystyrene blocks provide a thicker, more robust option suited for sculpting, prototyping, and insulation with high density and durability. Choosing between sheets and blocks depends on the required thickness, structural strength, and intended use in projects or manufacturing.

Table of Comparison

| Feature | Polystyrene Sheet | Polystyrene Block |

|---|---|---|

| Form | Flat, thin layers | Thick, solid blocks |

| Density | Varies, typically 10-50 kg/m3 | Higher density, up to 100 kg/m3 |

| Applications | Insulation panels, model making, packaging | Structural insulation, bulk packaging, prototypes |

| Cutting & Shaping | Easy to cut, ideal for detailed shaping | Requires power tools for shaping |

| Thermal Insulation | Effective thermal barrier | Superior insulation due to thickness |

| Weight | Lightweight | Heavier due to compact form |

| Cost | Lower price per unit area | Higher price due to volume |

| Common Uses | Wall insulation, craft sheets | Foundation insulation, large scale models |

Overview: Polystyrene Sheet vs Polystyrene Block

Polystyrene sheets are thin, flat materials often used in insulation and packaging due to their flexibility and ease of cutting, while polystyrene blocks are thicker, rigid forms primarily utilized for structural applications and model prototyping. Sheets typically offer better surface finish and lightweight properties, making them ideal for decorative and craft uses, whereas blocks provide superior strength and moldability for industrial and architectural models. Both forms are available in expanded (EPS) or extruded (XPS) varieties, influencing their texture, density, and thermal insulation performance.

Key Differences in Structure and Composition

Polystyrene sheets are manufactured through extrusion, resulting in thin, uniform layers with a smooth surface ideal for packaging and display applications. Polystyrene blocks, typically produced by polymerizing styrene beads in molds, feature a dense, compact structure suited for insulation and construction uses. The primary composition remains polystyrene polymer, but the structural differences influence thermal resistance, rigidity, and application versatility.

Manufacturing Processes Compared

Polystyrene sheets are produced through continuous extrusion where molten polymer is forced through a flat die and rapidly cooled to form thin, uniform sheets, enabling precision thickness control for applications like signage and insulation. Polystyrene blocks are typically created using an expansion process where pre-expanded beads are molded and fused in a block shape, allowing for customization in size and density, widely used in packaging and construction. Sheet manufacturing emphasizes consistent surface quality and dimensional accuracy, while block production prioritizes bulk volume and ease of cutting into various shapes.

Typical Applications of Polystyrene Sheets

Polystyrene sheets are widely used in packaging, insulation, and signage due to their lightweight nature and ease of fabrication. These sheets offer excellent thermal resistance, making them ideal for construction insulation and temperature-controlled packaging. In contrast to polystyrene blocks, sheets provide a smooth surface suitable for printing and laminating applications.

Common Uses for Polystyrene Blocks

Polystyrene blocks are widely used in thermal insulation, packaging, and model building due to their lightweight and durable properties. Their rigid structure allows for effective cushioning in shipping applications and provides excellent insulation in construction and HVAC systems. These blocks are also favored for prototype modeling and craft projects where ease of cutting and shaping is essential.

Strength, Durability, and Load-Bearing Properties

Polystyrene sheets exhibit superior strength and rigidity, making them ideal for applications requiring flat, stable surfaces with moderate load-bearing capacity. Polystyrene blocks, while offering excellent insulation and versatility in shaping, generally have lower structural strength and durability compared to sheets, limiting their use in high-load scenarios. For projects demanding enhanced load-bearing properties and long-term durability, polystyrene sheets are the preferred choice over blocks.

Insulation Performance: Sheet vs Block

Polystyrene sheets offer superior insulation performance due to their uniform density and reduced thermal bridging, making them ideal for precise applications requiring consistent thermal resistance. Polystyrene blocks, while cost-effective and versatile, often have variable density and require additional processing to achieve comparable insulation properties. The sheet form's higher R-value per inch enhances energy efficiency in building insulation compared to the bulkier, less dense block counterparts.

Cost Considerations and Budgeting

Polystyrene sheets generally offer a lower cost per square foot compared to polystyrene blocks, making them a budget-friendly option for flat, uniform applications such as insulation or signage. Polystyrene blocks, while often more expensive due to their density and versatility for custom cutting, provide better value in projects requiring three-dimensional shaping or structural support. Careful budgeting should account for material cost, waste, and machining expenses to optimize overall project affordability.

Environmental Impact and Recycling Options

Polystyrene sheets generally have a lower environmental impact compared to polystyrene blocks due to their reduced thickness and material usage, which results in less plastic waste. Recycling options for polystyrene sheets are more limited because they are often contaminated with adhesives or coatings, whereas polystyrene blocks, commonly used in packaging and insulation, can be more easily collected and processed through specialized foam recycling programs. Both forms present challenges in recycling, but advancements in chemical recycling and densification technologies are improving the feasibility of reusing polystyrene materials more effectively.

Choosing the Right Polystyrene Material for Your Project

Polystyrene sheets offer a smooth, flat surface ideal for detailed crafting, signage, and architectural models, while polystyrene blocks provide bulk material suited for carving, prototyping, and insulation applications. Selecting the right material depends on project requirements such as thickness, durability, and ease of shaping, with sheets providing precision and blocks allowing for substantial structural modifications. Consider factors like density, thermal resistance, and finishing needs to ensure optimal performance and cost-effectiveness in your polystyrene-based project.

Polystyrene Sheet vs Polystyrene Block Infographic

materialdif.com

materialdif.com