Polystyrene exhibits higher stiffness compared to polyvinyl chloride (PVC), making it more rigid and less flexible under stress. This characteristic allows polystyrene to maintain shape and structural integrity in applications requiring firmness. In contrast, PVC offers greater flexibility, which is beneficial for uses that demand impact resistance and bendability.

Table of Comparison

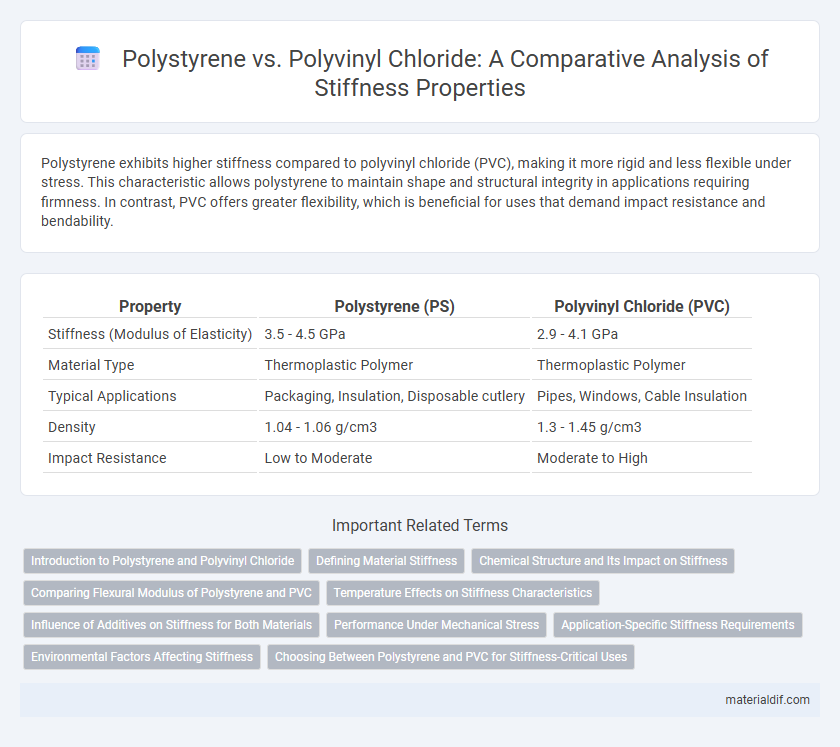

| Property | Polystyrene (PS) | Polyvinyl Chloride (PVC) |

|---|---|---|

| Stiffness (Modulus of Elasticity) | 3.5 - 4.5 GPa | 2.9 - 4.1 GPa |

| Material Type | Thermoplastic Polymer | Thermoplastic Polymer |

| Typical Applications | Packaging, Insulation, Disposable cutlery | Pipes, Windows, Cable Insulation |

| Density | 1.04 - 1.06 g/cm3 | 1.3 - 1.45 g/cm3 |

| Impact Resistance | Low to Moderate | Moderate to High |

Introduction to Polystyrene and Polyvinyl Chloride

Polystyrene exhibits higher stiffness compared to polyvinyl chloride due to its rigid aromatic polymer backbone, which restricts molecular movement. Polyvinyl chloride, with its flexible vinyl chloride units and plasticizer additives, offers enhanced ductility but lower stiffness. These fundamental differences in polymer structure dictate their mechanical properties and applications.

Defining Material Stiffness

Material stiffness measures resistance to deformation under applied force, quantified by the modulus of elasticity. Polystyrene exhibits higher stiffness with a modulus typically around 3-3.5 GPa, enabling it to maintain shape under stress, while polyvinyl chloride (PVC) shows lower stiffness ranging from 0.1 to 4 GPa depending on formulation, offering more flexibility. Understanding stiffness differences is crucial for applications requiring rigidity or flexibility, influencing material selection in manufacturing and design.

Chemical Structure and Its Impact on Stiffness

Polystyrene exhibits higher stiffness than polyvinyl chloride (PVC) due to its rigid aromatic benzene rings attached to the polymer backbone, which restrict molecular motion and enhance rigidity. In contrast, PVC contains flexible aliphatic chains and chlorine atoms, providing moderate stiffness with greater impact resistance and flexibility. The chemical structure's presence of bulky phenyl groups in polystyrene significantly contributes to its mechanical stiffness versus the more flexible PVC structure.

Comparing Flexural Modulus of Polystyrene and PVC

Polystyrene exhibits a flexural modulus typically ranging from 3,000 to 3,500 MPa, indicating a higher stiffness compared to polyvinyl chloride (PVC), which usually has a flexural modulus between 1,200 and 2,400 MPa. This difference in flexural modulus reflects polystyrene's greater rigidity and resistance to bending under applied stress relative to PVC. Engineers often select polystyrene for applications demanding superior structural stiffness while PVC is favored for flexibility and impact resistance.

Temperature Effects on Stiffness Characteristics

Polystyrene exhibits a higher stiffness at room temperature compared to polyvinyl chloride, but its stiffness drastically decreases as temperatures approach its glass transition point around 100degC. Polyvinyl chloride maintains more consistent stiffness over a wider temperature range due to its broader glass transition region near 80degC and better thermal stability. This temperature-dependent behavior makes polystyrene less suitable for applications requiring mechanical rigidity at elevated temperatures, whereas polyvinyl chloride performs reliably in such conditions.

Influence of Additives on Stiffness for Both Materials

Additives significantly influence the stiffness of polystyrene and polyvinyl chloride (PVC), with impact modifiers enhancing PVC's flexibility while plasticizers reduce polystyrene's brittleness. Reinforcing fillers like glass fibers increase the modulus of both polymers, resulting in improved rigidity and mechanical strength. The choice and concentration of additives directly affect the elastic modulus and overall stiffness, tailoring performance for specific applications.

Performance Under Mechanical Stress

Polystyrene exhibits higher stiffness compared to polyvinyl chloride (PVC), resulting in less deformation under mechanical stress, making it suitable for rigid applications. PVC offers greater flexibility and impact resistance but shows lower modulus of elasticity, which affects its performance under sustained loads. The choice between polystyrene and PVC depends on the balance between stiffness requirements and durability under mechanical strain in specific applications.

Application-Specific Stiffness Requirements

Polystyrene exhibits higher stiffness with a modulus of elasticity around 3.5 GPa, making it ideal for rigid packaging and disposable cutlery that require structural integrity. Polyvinyl chloride (PVC), with a lower stiffness typically between 2.4 to 3.0 GPa, offers more flexibility, which suits applications like pipes, window frames, and medical devices that demand impact resistance and slight deformation. Selecting between polystyrene and PVC depends on the specific stiffness requirements of the application, balancing rigidity and flexibility for performance and durability.

Environmental Factors Affecting Stiffness

Polystyrene stiffness is highly susceptible to environmental factors such as temperature fluctuations and UV exposure, leading to brittleness and reduced mechanical integrity over time. In contrast, polyvinyl chloride (PVC) demonstrates superior resistance to these environmental stressors, maintaining its stiffness and durability under similar conditions. Moisture absorption impacts PVC stiffness less significantly than polystyrene, which tends to undergo stiffness degradation when exposed to humid environments.

Choosing Between Polystyrene and PVC for Stiffness-Critical Uses

Polystyrene exhibits higher rigidity with a tensile modulus around 3-3.5 GPa, making it suitable for applications requiring stiffness and lightweight properties. Polyvinyl chloride (PVC) offers lower stiffness, typically near 2-2.5 GPa, but provides superior impact resistance and flexibility. Selecting between polystyrene and PVC for stiffness-critical uses depends on balancing the need for structural rigidity with factors like durability and environmental exposure.

Polystyrene Stiffness vs Polyvinyl Chloride Stiffness Infographic

materialdif.com

materialdif.com