Polystyrene moldings offer superior ease of customization and a smoother finish compared to PVC moldings, making them ideal for detailed decorative applications. They are lightweight and cost-effective, providing excellent durability without the rigidity often associated with PVC. Polystyrene's resistance to moisture and chemicals further enhances its suitability for both indoor and outdoor uses, outperforming many PVC options in versatility.

Table of Comparison

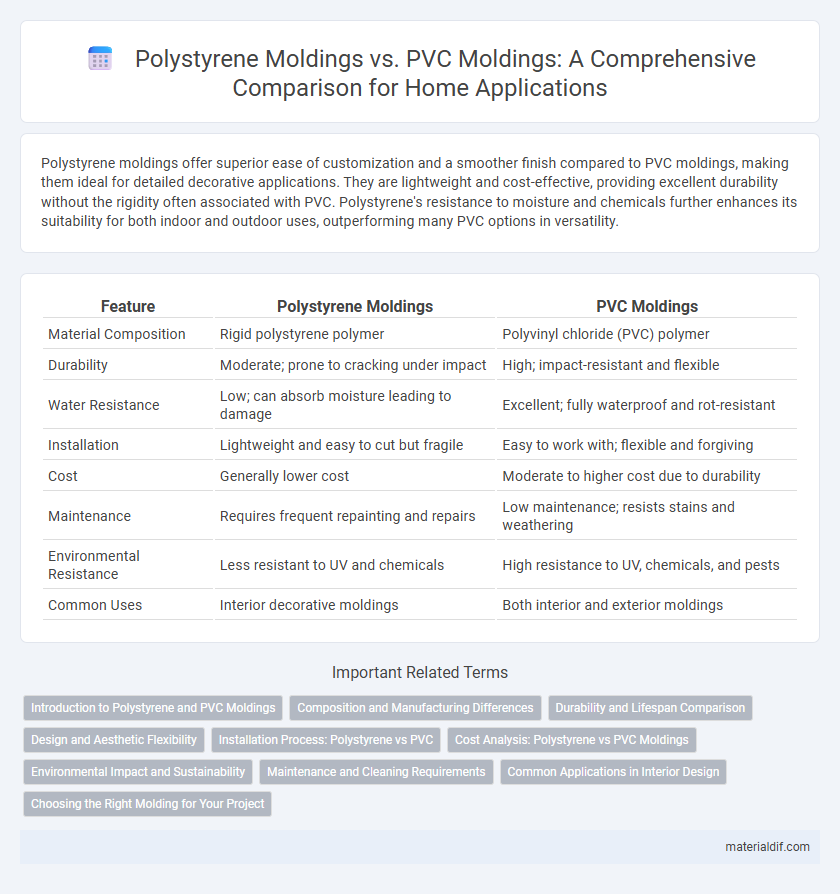

| Feature | Polystyrene Moldings | PVC Moldings |

|---|---|---|

| Material Composition | Rigid polystyrene polymer | Polyvinyl chloride (PVC) polymer |

| Durability | Moderate; prone to cracking under impact | High; impact-resistant and flexible |

| Water Resistance | Low; can absorb moisture leading to damage | Excellent; fully waterproof and rot-resistant |

| Installation | Lightweight and easy to cut but fragile | Easy to work with; flexible and forgiving |

| Cost | Generally lower cost | Moderate to higher cost due to durability |

| Maintenance | Requires frequent repainting and repairs | Low maintenance; resists stains and weathering |

| Environmental Resistance | Less resistant to UV and chemicals | High resistance to UV, chemicals, and pests |

| Common Uses | Interior decorative moldings | Both interior and exterior moldings |

Introduction to Polystyrene and PVC Moldings

Polystyrene moldings are lightweight, cost-effective, and easy to install, making them ideal for decorative trims and architectural details. PVC moldings offer superior moisture resistance and durability, suitable for both interior and exterior applications where exposure to elements is a concern. Both materials provide versatile design options, but polystyrene excels in affordability while PVC stands out for longevity and weather resistance.

Composition and Manufacturing Differences

Polystyrene moldings are composed primarily of polystyrene resin, a lightweight, rigid thermoplastic formed through polymerization of styrene monomers, while PVC moldings are made from polyvinyl chloride, a versatile thermoplastic polymer derived from vinyl chloride monomers. Polystyrene moldings are typically produced using injection molding or extrusion processes, allowing for detailed, dimensionally stable parts with smooth surfaces, whereas PVC moldings often undergo extrusion or calendering, offering higher flexibility and superior chemical resistance. The inherent differences in polymer composition result in polystyrene moldings being more brittle and less UV resistant compared to the more durable, weather-resistant PVC moldings suited for outdoor applications.

Durability and Lifespan Comparison

Polystyrene moldings offer moderate durability with resistance to moisture and impact, but may yellow or become brittle over time when exposed to UV light. PVC moldings provide superior longevity due to enhanced weather resistance, flexibility, and higher impact strength, making them ideal for exterior applications. The average lifespan of PVC moldings ranges from 20 to 40 years, significantly outlasting polystyrene moldings, which typically last around 10 to 15 years under similar conditions.

Design and Aesthetic Flexibility

Polystyrene moldings offer superior design and aesthetic flexibility due to their ability to be easily shaped into intricate patterns and detailed profiles compared to PVC moldings. Their smoother finish and easier priming capabilities allow for a wide range of paint options, enhancing customization for interior decor. In contrast, PVC moldings tend to have a more rigid structure and limited design variations, making polystyrene the preferred choice for projects requiring elaborate, decorative trim work.

Installation Process: Polystyrene vs PVC

Polystyrene moldings offer a lightweight and flexible option, making the installation process faster and easier with standard adhesives or nails, often requiring minimal surface preparation. PVC moldings, being denser and more rigid, typically demand specialized tools for cutting and more precise fitting, sometimes necessitating screws or heavy-duty adhesives for secure installation. Both materials are moisture-resistant, but polystyrene's softness can reduce installation damage compared to the tougher PVC moldings.

Cost Analysis: Polystyrene vs PVC Moldings

Polystyrene moldings typically offer a lower cost compared to PVC moldings due to less expensive raw materials and simpler manufacturing processes. PVC moldings often incur higher production costs attributed to their durability and chemical resistance, which demand more complex compounding and extrusion techniques. When evaluating cost-effectiveness, polystyrene is preferred for budget-conscious projects, whereas PVC provides long-term value in demanding environments despite higher initial expenses.

Environmental Impact and Sustainability

Polystyrene moldings exhibit lower recyclability rates compared to PVC moldings, resulting in a more significant environmental burden due to their persistence in landfills. The production of PVC moldings involves harmful additives like phthalates and chlorine, which can release toxic emissions during manufacturing and disposal, negatively impacting ecosystems. Polystyrene moldings, while less toxic, contribute to microplastic pollution, highlighting the need for sustainable alternatives with improved biodegradability and environmental compatibility.

Maintenance and Cleaning Requirements

Polystyrene moldings require minimal maintenance due to their resistance to moisture, making them easy to clean with mild soap and water without fear of warping or damage. PVC moldings offer similar low-maintenance benefits but tend to be more durable against stains and scratches, requiring occasional cleaning with non-abrasive cleaners to preserve their appearance. Both materials resist mold and mildew, reducing the frequency of deep cleaning compared to wood moldings.

Common Applications in Interior Design

Polystyrene moldings are commonly used in interior design for decorative trim, crown molding, and ceiling medallions due to their lightweight nature and ease of customization. PVC moldings are favored for moisture-prone areas such as bathrooms and kitchens because of their water resistance and durability. Both materials provide cost-effective alternatives to traditional wood moldings, enhancing aesthetic appeal while accommodating specific environmental conditions.

Choosing the Right Molding for Your Project

Polystyrene moldings offer superior ease of installation and cost-effectiveness, making them ideal for lightweight interior projects such as decorative trims and baseboards. PVC moldings provide enhanced moisture resistance and durability, suitable for areas exposed to humidity or outdoor environments. Selecting the right molding depends on project requirements, balancing budget constraints with environmental exposure to ensure long-lasting performance.

Polystyrene Moldings vs PVC Moldings Infographic

materialdif.com

materialdif.com