Biodegradable polystyrene offers an eco-friendly alternative to conventional polystyrene by decomposing naturally and reducing environmental pollution. Unlike traditional polystyrene, which persists in landfills for centuries, biodegradable variants break down through microbial action, minimizing long-term waste accumulation. This innovation supports sustainable packaging without compromising the material's lightweight and insulating properties.

Table of Comparison

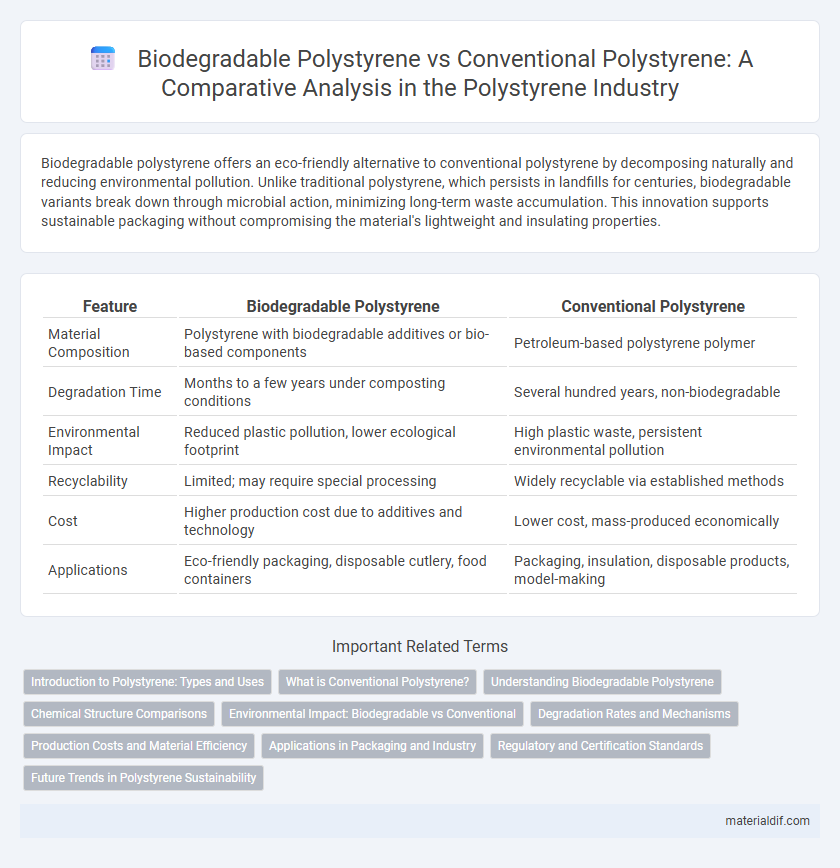

| Feature | Biodegradable Polystyrene | Conventional Polystyrene |

|---|---|---|

| Material Composition | Polystyrene with biodegradable additives or bio-based components | Petroleum-based polystyrene polymer |

| Degradation Time | Months to a few years under composting conditions | Several hundred years, non-biodegradable |

| Environmental Impact | Reduced plastic pollution, lower ecological footprint | High plastic waste, persistent environmental pollution |

| Recyclability | Limited; may require special processing | Widely recyclable via established methods |

| Cost | Higher production cost due to additives and technology | Lower cost, mass-produced economically |

| Applications | Eco-friendly packaging, disposable cutlery, food containers | Packaging, insulation, disposable products, model-making |

Introduction to Polystyrene: Types and Uses

Polystyrene is a versatile thermoplastic polymer commonly found in two types: conventional polystyrene and biodegradable polystyrene. Conventional polystyrene is widely used in packaging, insulation, and disposable containers due to its rigidity and low cost, while biodegradable polystyrene incorporates additives or blends designed to break down more rapidly in natural environments. Understanding these types highlights their respective environmental impacts and practical applications in industries such as food service and construction.

What is Conventional Polystyrene?

Conventional polystyrene is a synthetic aromatic hydrocarbon polymer made from the monomer styrene, widely used in packaging, insulation, and disposable cutlery due to its lightweight, rigid, and insulating properties. It is non-biodegradable, contributing significantly to environmental pollution and landfill accumulation because it resists natural decomposition processes. Its production involves petroleum-based raw materials, resulting in a polymer that persists in ecosystems for hundreds of years without breaking down.

Understanding Biodegradable Polystyrene

Biodegradable polystyrene is engineered to break down more rapidly through microbial activity compared to conventional polystyrene, which is resistant to natural degradation and persists in the environment for hundreds of years. This innovation incorporates additives such as starch or other organic compounds that accelerate decomposition under specific conditions, promoting reduced environmental impact. Understanding these chemical modifications and biodegradation mechanisms is essential for evaluating the sustainability and practical applications of biodegradable polystyrene in waste management and product design.

Chemical Structure Comparisons

Biodegradable polystyrene incorporates additives or copolymers like polylactic acid or starch to introduce hydrolysable ester bonds within its polymer matrix, facilitating microbial degradation, whereas conventional polystyrene consists solely of long chains of styrene monomers with strong C-C bonds resistant to biodegradation. The presence of functional groups such as ester linkages in biodegradable variants alters polymer crystallinity and enhances susceptibility to enzymatic cleavage, contrasting with the purely aromatic hydrocarbon backbone of standard polystyrene. Chemical modifications in biodegradable polystyrene also lead to differences in molecular weight distribution and thermal properties compared to the chemically inert and hydrophobic nature of conventional polystyrene.

Environmental Impact: Biodegradable vs Conventional

Biodegradable polystyrene decomposes more rapidly through microbial action, significantly reducing long-term environmental pollution compared to conventional polystyrene, which can persist in ecosystems for hundreds of years. Conventional polystyrene contributes extensively to plastic waste buildup, marine pollution, and harmful microplastic formation, posing risks to wildlife and human health. Many biodegradable alternatives are engineered to break down under industrial composting conditions, offering a more sustainable solution for reducing environmental footprints.

Degradation Rates and Mechanisms

Biodegradable polystyrene breaks down significantly faster than conventional polystyrene, with degradation rates accelerated by microbial activity and environmental factors such as UV exposure and moisture. Conventional polystyrene degrades over hundreds of years primarily through slow photodegradation and physical fragmentation without substantial microbial involvement. The enhanced degradation mechanisms in biodegradable variants often involve additives like starch or specific polymers that promote enzymatic breakdown and improved environmental assimilation.

Production Costs and Material Efficiency

Biodegradable polystyrene typically incurs higher production costs compared to conventional polystyrene due to the use of specialized raw materials and advanced manufacturing processes. Material efficiency in biodegradable polystyrene is often enhanced by the incorporation of renewable additives that promote breakdown, whereas conventional polystyrene benefits from established large-scale production methods yielding lower waste and cost per unit. The economic trade-offs between these materials influence their adoption in packaging and consumer goods industries.

Applications in Packaging and Industry

Biodegradable polystyrene offers an eco-friendly alternative to conventional polystyrene by breaking down more rapidly in the environment, significantly reducing long-term pollution in packaging applications. Its use in food containers, disposable cutlery, and insulation materials aligns with growing sustainability regulations and consumer demand for green products. Conventional polystyrene remains favored for its durability and cost-effectiveness in heavy-duty industrial packaging but faces increasing restrictions due to environmental concerns.

Regulatory and Certification Standards

Biodegradable polystyrene is subject to emerging regulatory frameworks emphasizing environmental safety, such as ASTM D6400 and EN 13432 standards, which define criteria for compostability and biodegradability. Conventional polystyrene lacks such certifications and faces increasing restrictions due to its persistence in the environment and challenges in waste management. Compliance with international certifications like OK Compost and TUV Austria enhances the market acceptance and environmental credibility of biodegradable polystyrene products.

Future Trends in Polystyrene Sustainability

Biodegradable polystyrene is gaining traction as environmental regulations tighten and consumer demand shifts towards eco-friendly materials, leveraging advanced bio-based additives and enhanced polymer blending techniques to improve decomposition rates. Conventional polystyrene remains widely used due to its durability and cost-efficiency, but innovations in chemical recycling and circular economy models are driving its gradual transformation. Future trends in polystyrene sustainability emphasize integrating biodegradable components with scalable recycling infrastructure to reduce plastic pollution and carbon footprint across industries.

Biodegradable Polystyrene vs Conventional Polystyrene Infographic

materialdif.com

materialdif.com