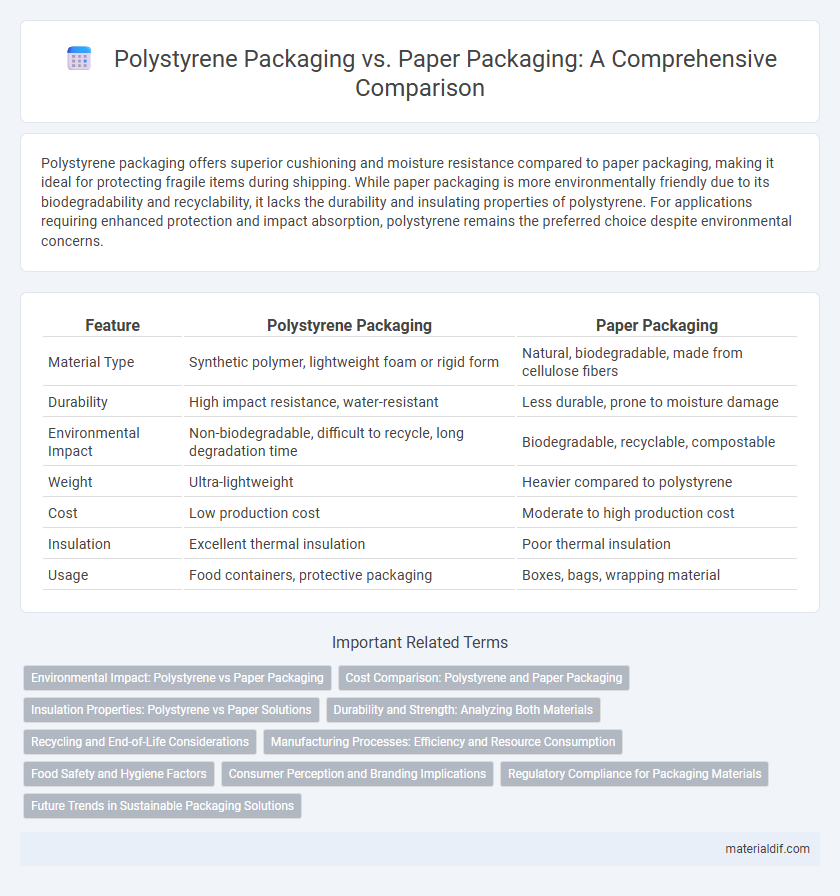

Polystyrene packaging offers superior cushioning and moisture resistance compared to paper packaging, making it ideal for protecting fragile items during shipping. While paper packaging is more environmentally friendly due to its biodegradability and recyclability, it lacks the durability and insulating properties of polystyrene. For applications requiring enhanced protection and impact absorption, polystyrene remains the preferred choice despite environmental concerns.

Table of Comparison

| Feature | Polystyrene Packaging | Paper Packaging |

|---|---|---|

| Material Type | Synthetic polymer, lightweight foam or rigid form | Natural, biodegradable, made from cellulose fibers |

| Durability | High impact resistance, water-resistant | Less durable, prone to moisture damage |

| Environmental Impact | Non-biodegradable, difficult to recycle, long degradation time | Biodegradable, recyclable, compostable |

| Weight | Ultra-lightweight | Heavier compared to polystyrene |

| Cost | Low production cost | Moderate to high production cost |

| Insulation | Excellent thermal insulation | Poor thermal insulation |

| Usage | Food containers, protective packaging | Boxes, bags, wrapping material |

Environmental Impact: Polystyrene vs Paper Packaging

Polystyrene packaging generates significant environmental concerns due to its non-biodegradable nature, persisting in landfills and marine environments for centuries, while paper packaging decomposes more rapidly and is often sourced from renewable materials. The production of polystyrene involves petrochemical processes that emit greenhouse gases and use non-renewable resources, contrasting with paper packaging's lower carbon footprint and higher recyclability rates. Despite its lightweight and protective qualities, polystyrene's environmental impact is substantially greater than paper packaging, which supports sustainable waste management and reduces ecological harm.

Cost Comparison: Polystyrene and Paper Packaging

Polystyrene packaging typically offers lower material and production costs compared to paper packaging, making it a cost-effective choice for manufacturers seeking affordability in bulk packaging solutions. Paper packaging often involves higher expenses due to raw material sourcing, processing, and environmental compliance measures, driving up overall costs. The durability and lightweight nature of polystyrene further reduce transportation expenses, enhancing its cost benefits over paper alternatives in packaging applications.

Insulation Properties: Polystyrene vs Paper Solutions

Polystyrene packaging offers superior insulation properties compared to paper solutions, maintaining temperature stability effectively for perishable goods during transit. Its closed-cell structure provides enhanced thermal resistance, reducing heat transfer and preserving product freshness. Paper packaging, while biodegradable and eco-friendly, lacks the same insulation efficiency, often requiring additional layers or treatments to approach polystyrene's performance.

Durability and Strength: Analyzing Both Materials

Polystyrene packaging exhibits superior durability and strength compared to paper packaging due to its rigid, impact-resistant structure, making it ideal for protecting fragile items during transit. Paper packaging, while biodegradable and lightweight, generally lacks the tensile strength and moisture resistance inherent in polystyrene, leading to potential deformation and reduced protective capabilities. The resilience of polystyrene against external forces enhances its application in long-term storage and shipping, whereas paper packaging is preferred for lightweight, short-term use with environmentally conscious goals.

Recycling and End-of-Life Considerations

Polystyrene packaging presents recycling challenges due to its low density and contamination issues, resulting in limited acceptance by recycling facilities compared to paper packaging, which is widely recycled and biodegradable. End-of-life management for polystyrene often involves landfill disposal or energy recovery via incineration, posing environmental concerns related to microplastic pollution and greenhouse gas emissions. In contrast, paper packaging decomposes more readily in natural environments, offering a more sustainable option with greater potential for closed-loop recycling and reduced ecological impact.

Manufacturing Processes: Efficiency and Resource Consumption

Polystyrene packaging manufacturing relies on polymerization of styrene monomers, enabling rapid production with precise molding and minimal material waste, contributing to high efficiency in large-scale operations. In contrast, paper packaging production involves pulping, bleaching, and pressing natural fibers, processes that are generally more resource-intensive and time-consuming due to water consumption and energy usage. Polystyrene's lightweight characteristics also reduce transportation energy, whereas paper packaging often demands heavier loads, impacting overall resource consumption in the supply chain.

Food Safety and Hygiene Factors

Polystyrene packaging offers superior moisture resistance and prevents contamination, making it highly effective in maintaining food safety and hygiene compared to paper packaging. Unlike paper, polystyrene is non-porous, reducing bacterial growth and minimizing the risk of foodborne illnesses. Its durability under various temperature conditions further ensures the integrity and cleanliness of food products during storage and transport.

Consumer Perception and Branding Implications

Polystyrene packaging is often perceived by consumers as lightweight, durable, and effective at protecting products during shipping, enhancing brand reliability in sectors like electronics and food delivery. In contrast, paper packaging is increasingly associated with eco-friendliness and sustainability, appealing to environmentally conscious consumers and boosting brand image in green marketing efforts. Brands leveraging polystyrene must address environmental concerns to maintain trust, while those using paper packaging can capitalize on growing demand for biodegradable and recyclable materials to strengthen consumer loyalty.

Regulatory Compliance for Packaging Materials

Polystyrene packaging often faces stricter regulatory scrutiny due to environmental concerns and recycling challenges compared to paper packaging, which benefits from more established biodegradable and compostable certifications. Regulations such as the EU's Single-Use Plastics Directive and various U.S. state bans on polystyrene foam highlight compliance hurdles for polystyrene manufacturers. Paper packaging, governed by standards like ASTM D6868 for compostability and FDA regulations for food contact safety, generally aligns more easily with sustainability mandates and circular economy goals.

Future Trends in Sustainable Packaging Solutions

Polystyrene packaging, known for its lightweight and insulating properties, faces increasing scrutiny due to environmental concerns, driving innovation towards biodegradable and recyclable polystyrene alternatives. Paper packaging solutions are evolving with enhanced durability and water resistance, leveraging plant-based coatings and fiber technology to meet sustainability demands. Future trends prioritize circular economy models and advanced material blends that combine the performance benefits of polystyrene with the biodegradability of paper, aiming to reduce carbon footprints and improve waste management efficiency.

Polystyrene Packaging vs Paper Packaging Infographic

materialdif.com

materialdif.com