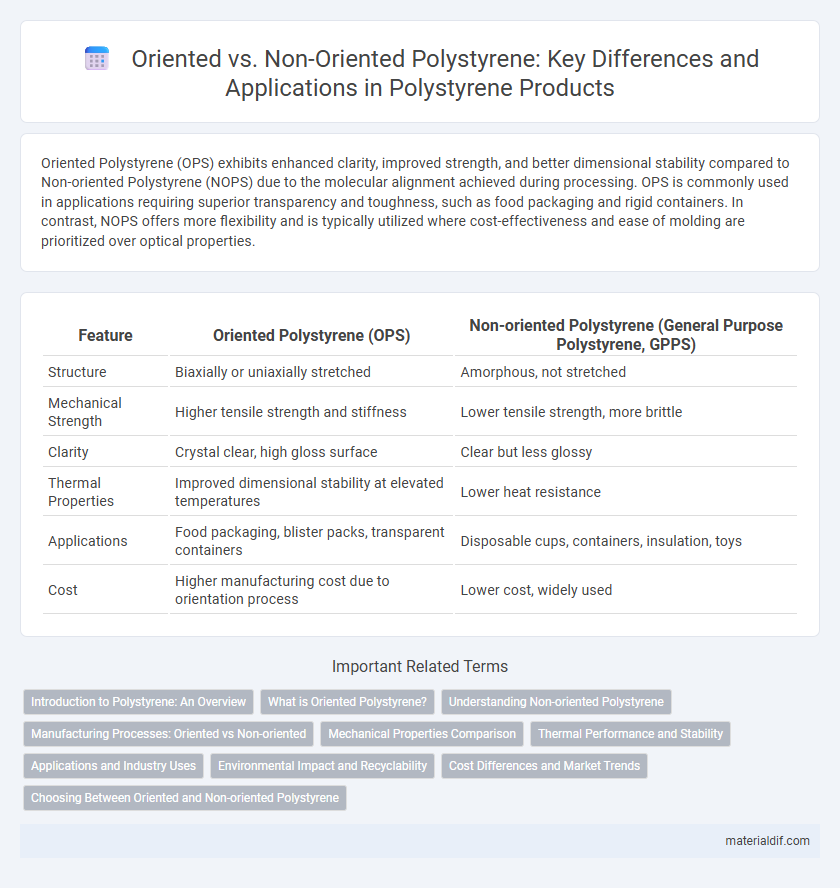

Oriented Polystyrene (OPS) exhibits enhanced clarity, improved strength, and better dimensional stability compared to Non-oriented Polystyrene (NOPS) due to the molecular alignment achieved during processing. OPS is commonly used in applications requiring superior transparency and toughness, such as food packaging and rigid containers. In contrast, NOPS offers more flexibility and is typically utilized where cost-effectiveness and ease of molding are prioritized over optical properties.

Table of Comparison

| Feature | Oriented Polystyrene (OPS) | Non-oriented Polystyrene (General Purpose Polystyrene, GPPS) |

|---|---|---|

| Structure | Biaxially or uniaxially stretched | Amorphous, not stretched |

| Mechanical Strength | Higher tensile strength and stiffness | Lower tensile strength, more brittle |

| Clarity | Crystal clear, high gloss surface | Clear but less glossy |

| Thermal Properties | Improved dimensional stability at elevated temperatures | Lower heat resistance |

| Applications | Food packaging, blister packs, transparent containers | Disposable cups, containers, insulation, toys |

| Cost | Higher manufacturing cost due to orientation process | Lower cost, widely used |

Introduction to Polystyrene: An Overview

Oriented polystyrene (OPS) enhances material strength and clarity by aligning polymer chains through stretching processes, making it ideal for rigid packaging applications. Non-oriented polystyrene (general purpose PS) exhibits isotropic properties with balanced mechanical and thermal characteristics, suited for disposable containers and insulation. The choice between oriented and non-oriented polystyrene depends on performance requirements such as stiffness, impact resistance, and transparency.

What is Oriented Polystyrene?

Oriented polystyrene (OPS) is a type of polystyrene film that undergoes a stretching process to align its polymer chains, resulting in improved mechanical strength, clarity, and barrier properties compared to non-oriented polystyrene. This orientation enhances tensile strength and dimensional stability, making OPS ideal for packaging applications requiring durability and resistance to tearing. Non-oriented polystyrene, by contrast, lacks this molecular alignment and exhibits lower strength and clarity, limiting its use in high-performance packaging.

Understanding Non-oriented Polystyrene

Non-oriented polystyrene (NOPS) is an amorphous polymer characterized by its random molecular alignment, resulting in lower tensile strength and reduced stiffness compared to oriented polystyrene. This material offers higher impact resistance and better clarity, making it suitable for applications like packaging, insulation, and disposable consumer products. Unlike oriented polystyrene, NOPS lacks directional mechanical properties, leading to isotropic performance in molding and extrusion processes.

Manufacturing Processes: Oriented vs Non-oriented

Oriented polystyrene (OPS) is manufactured through a biaxial stretching process that aligns polymer chains, enhancing strength and clarity, whereas non-oriented polystyrene (NOPS) undergoes conventional casting or extrusion without molecular alignment, resulting in lower mechanical properties. The manufacturing of OPS involves reheating and stretching sheets in both machine and transverse directions, creating a structured molecular orientation that improves barrier performance and stiffness. In contrast, NOPS production is simpler and less energy-intensive, producing a more amorphous material with reduced impact resistance and optical clarity.

Mechanical Properties Comparison

Oriented polystyrene exhibits significantly enhanced mechanical properties compared to non-oriented polystyrene, including increased tensile strength and improved impact resistance due to molecular alignment during the orientation process. Non-oriented polystyrene typically displays brittleness and lower dimensional stability, resulting in weaker mechanical performance under stress. The orientation process induces anisotropy, making oriented polystyrene suitable for applications requiring higher durability and mechanical reliability.

Thermal Performance and Stability

Oriented polystyrene exhibits enhanced thermal performance and dimensional stability compared to non-oriented polystyrene, owing to the molecular alignment achieved during the stretching process. This orientation improves heat resistance and reduces thermal expansion, making it suitable for applications requiring consistent performance under elevated temperatures. Non-oriented polystyrene, by contrast, tends to have lower thermal stability and may deform or lose shape when exposed to heat.

Applications and Industry Uses

Oriented polystyrene (OPS) is widely used in packaging applications such as food containers, trays, and clamshells due to its enhanced clarity, rigidity, and impact resistance compared to non-oriented polystyrene (PS). Non-oriented polystyrene finds extensive use in disposable cutlery, CD cases, and insulation materials where flexibility and cost-efficiency are prioritized. The packaging and consumer goods industries leverage OPS for premium product presentation, while non-oriented PS serves better in everyday items requiring ease of manufacturing and lower material costs.

Environmental Impact and Recyclability

Oriented polystyrene (OPS) exhibits a more uniform molecular alignment, which enhances its mechanical properties but complicates recycling due to its specialized structure, often requiring dedicated sorting and processing facilities. Non-oriented polystyrene (PS) is generally easier to recycle as it lacks orientation, allowing for more straightforward mechanical recycling, though it may suffer from lower durability and a shorter lifecycle. Both types contribute to environmental concerns related to non-biodegradability and landfill accumulation, but improved recycling technologies and material recovery systems are critical for mitigating their ecological footprint.

Cost Differences and Market Trends

Oriented polystyrene (OPS) generally incurs higher production costs than non-oriented polystyrene (PS) due to additional processing steps like biaxial stretching, which enhance material strength and clarity. Market trends indicate increasing demand for OPS in packaging and food containers driven by superior barrier properties and durability, leading to a steady price premium over conventional PS. Cost-sensitive applications continue to favor non-oriented polystyrene because of its lower price and adequate performance for products like disposable cutlery and insulation panels.

Choosing Between Oriented and Non-oriented Polystyrene

Oriented polystyrene offers enhanced strength, clarity, and dimensional stability due to molecular alignment during manufacturing, making it ideal for packaging and insulation applications. Non-oriented polystyrene, with its isotropic properties, provides greater flexibility and is commonly used in disposable cutlery and CD cases. Choosing between oriented and non-oriented polystyrene depends on the specific requirements for mechanical performance, transparency, and cost-effectiveness in the intended application.

Oriented Polystyrene vs Non-oriented Polystyrene Infographic

materialdif.com

materialdif.com