Crystal polystyrene offers a clear, rigid structure that is ideal for packaging and display applications requiring transparency and durability. Foam polystyrene, known for its lightweight and insulating properties, is commonly used in protective packaging and thermal insulation. Choosing between crystal and foam polystyrene depends on the need for visual clarity versus cushioning and insulation performance.

Table of Comparison

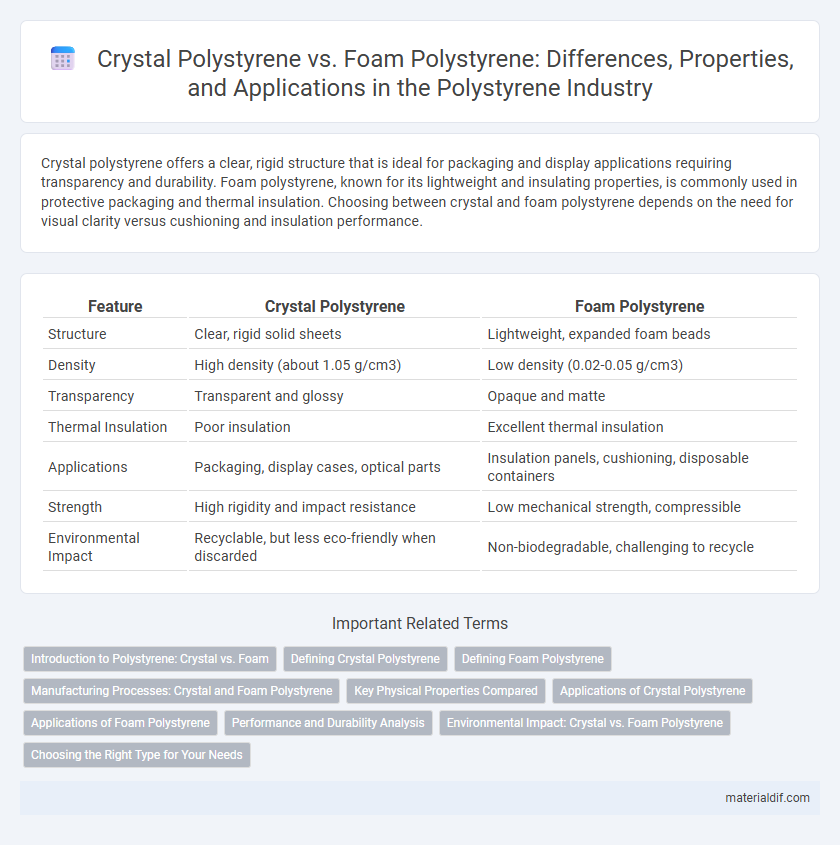

| Feature | Crystal Polystyrene | Foam Polystyrene |

|---|---|---|

| Structure | Clear, rigid solid sheets | Lightweight, expanded foam beads |

| Density | High density (about 1.05 g/cm3) | Low density (0.02-0.05 g/cm3) |

| Transparency | Transparent and glossy | Opaque and matte |

| Thermal Insulation | Poor insulation | Excellent thermal insulation |

| Applications | Packaging, display cases, optical parts | Insulation panels, cushioning, disposable containers |

| Strength | High rigidity and impact resistance | Low mechanical strength, compressible |

| Environmental Impact | Recyclable, but less eco-friendly when discarded | Non-biodegradable, challenging to recycle |

Introduction to Polystyrene: Crystal vs. Foam

Crystal polystyrene is a transparent, rigid thermoplastic known for its clarity and high impact resistance, making it ideal for packaging and laboratory ware. Foam polystyrene, also known as expanded polystyrene (EPS), is lightweight, insulating, and shock-absorbing, commonly used in construction, food containers, and packaging materials. Both forms are derived from the polystyrene polymer but differ significantly in structure, density, and applications.

Defining Crystal Polystyrene

Crystal Polystyrene, also known as GPPS (General Purpose Polystyrene), is a transparent, rigid thermoplastic polymer characterized by its high clarity and glossy finish. Unlike Foam Polystyrene, which is expanded and contains air pockets for insulation and cushioning, Crystal Polystyrene is solid and primarily used in applications requiring aesthetic appeal and dimensional stability such as clear packaging and disposable cutlery. Its density and rigidity provide excellent structural integrity but limited impact resistance compared to foam variants.

Defining Foam Polystyrene

Foam Polystyrene, also known as expanded polystyrene (EPS), is a lightweight, porous material created by expanding polystyrene beads with steam, resulting in a cellular structure filled with air. This structure significantly enhances thermal insulation and shock absorption properties compared to solid crystal polystyrene, which is dense and rigid. Foam polystyrene is widely used in packaging, insulation, and disposable food containers due to its low density and excellent cushioning characteristics.

Manufacturing Processes: Crystal and Foam Polystyrene

Crystal polystyrene is manufactured through a suspension polymerization process, producing a transparent, rigid material ideal for applications requiring clarity and strength. Foam polystyrene, on the other hand, is created by expanding polystyrene beads with a blowing agent, resulting in a lightweight, insulating material with excellent thermal resistance. The manufacturing differences significantly affect the density, cellular structure, and end-use properties of each polystyrene variant.

Key Physical Properties Compared

Crystal polystyrene exhibits a rigid, glossy structure with high clarity and excellent dimensional stability, making it ideal for applications requiring transparency and precision. Foam polystyrene, characterized by its lightweight, low density, and superior thermal insulation properties, offers enhanced cushioning and shock absorption in packaging and insulation uses. The density of crystal polystyrene ranges from 1.04 to 1.06 g/cm3, whereas foam polystyrene density can vary between 0.01 to 0.05 g/cm3, reflecting significant differences in strength and application suitability.

Applications of Crystal Polystyrene

Crystal Polystyrene (GPPS) is widely used in applications requiring clarity, rigidity, and ease of decoration, making it ideal for packaging, household items, and display products. Its transparent properties allow for high-quality printing and labeling, commonly seen in cosmetic containers, food packaging, and laboratory ware. Unlike Foam Polystyrene, which is preferred for insulation and cushioning, Crystal Polystyrene excels in structural and aesthetic uses where visual appeal and precision are crucial.

Applications of Foam Polystyrene

Foam polystyrene, known for its lightweight and insulating properties, is widely used in packaging to protect fragile items during shipping and handling. Its excellent thermal insulation makes it a preferred material in building construction for wall and roof insulation. Additionally, foam polystyrene serves as a core material in composite panels, contributing to energy efficiency in refrigeration and cold storage applications.

Performance and Durability Analysis

Crystal polystyrene, known for its high transparency and rigidity, offers superior mechanical strength and resistance to impact compared to foam polystyrene. Foam polystyrene, characterized by its lightweight cellular structure, provides excellent thermal insulation but exhibits lower structural durability and is more prone to deformation under stress. Performance analysis highlights crystal polystyrene's suitability in applications demanding clarity and rigidity, whereas foam polystyrene excels in insulating and cushioning roles despite its reduced load-bearing capacity.

Environmental Impact: Crystal vs. Foam Polystyrene

Crystal polystyrene is primarily composed of solid, transparent beads that are recyclable but slower to decompose, contributing to long-term environmental pollution if not properly managed. Foam polystyrene, also known as expanded polystyrene (EPS), contains trapped air bubbles making it lightweight but more prone to breakage and difficult to recycle, often accumulating in landfills and oceans where it persists for centuries. Both materials pose environmental challenges, but foam polystyrene has a higher risk of microplastic formation and greater ecological harm due to its widespread use in disposable packaging.

Choosing the Right Type for Your Needs

Crystal polystyrene offers a rigid, transparent structure ideal for packaging and display applications requiring clarity and durability, while foam polystyrene provides lightweight insulation and cushioning properties suited for thermal protection and shock absorption. Selecting the right type depends on balancing factors like structural strength, thermal resistance, and cost-efficiency specific to your project's requirements. Consider crystal polystyrene for visual appeal and mechanical strength, and foam polystyrene for insulation and impact mitigation.

Crystal Polystyrene vs Foam Polystyrene Infographic

materialdif.com

materialdif.com