Thermoforming polystyrene involves heating a plastic sheet until pliable and then molding it into shape, offering cost-effective production for thin-walled, large parts with flexible design changes. Injection molding of polystyrene melts plastic pellets and injects them into a mold cavity, providing high precision, detailed components, and efficient mass production. While thermoforming suits simple shapes and shorter runs, injection molding delivers higher accuracy and durability for complex, high-volume polystyrene products.

Table of Comparison

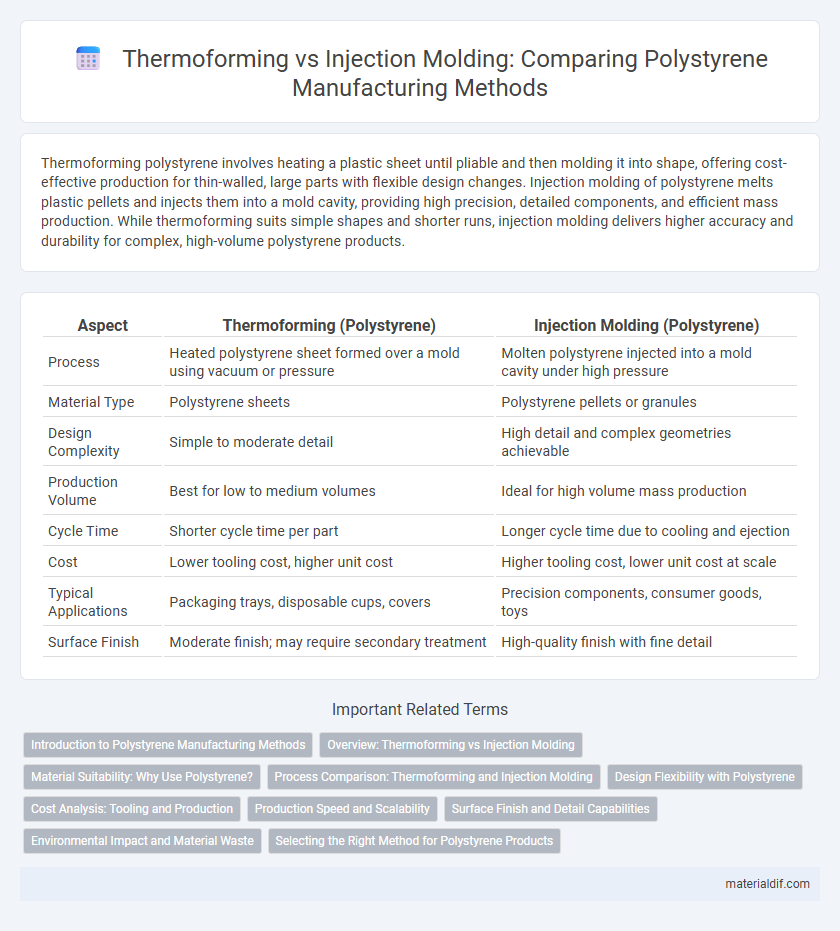

| Aspect | Thermoforming (Polystyrene) | Injection Molding (Polystyrene) |

|---|---|---|

| Process | Heated polystyrene sheet formed over a mold using vacuum or pressure | Molten polystyrene injected into a mold cavity under high pressure |

| Material Type | Polystyrene sheets | Polystyrene pellets or granules |

| Design Complexity | Simple to moderate detail | High detail and complex geometries achievable |

| Production Volume | Best for low to medium volumes | Ideal for high volume mass production |

| Cycle Time | Shorter cycle time per part | Longer cycle time due to cooling and ejection |

| Cost | Lower tooling cost, higher unit cost | Higher tooling cost, lower unit cost at scale |

| Typical Applications | Packaging trays, disposable cups, covers | Precision components, consumer goods, toys |

| Surface Finish | Moderate finish; may require secondary treatment | High-quality finish with fine detail |

Introduction to Polystyrene Manufacturing Methods

Thermoforming and injection molding represent two primary manufacturing methods for polystyrene, each offering distinct advantages based on product requirements. Thermoforming involves heating polystyrene sheets until pliable, then shaping them over molds, making it ideal for large, lightweight, and thin-walled products. Injection molding melts polystyrene pellets and injects the molten material into precise molds, providing high accuracy and repeatability suitable for complex and detailed components.

Overview: Thermoforming vs Injection Molding

Thermoforming of polystyrene involves heating sheets until pliable and shaping them over molds, making it ideal for large parts with thin walls and simple geometries. Injection molding uses molten polystyrene injected into precise molds, producing high-strength, complex components with excellent surface finishes and tight tolerances. Thermoforming offers lower tooling costs and faster prototyping, whereas injection molding excels in high-volume production and detailed part complexity.

Material Suitability: Why Use Polystyrene?

Polystyrene's low melting point and excellent flow characteristics make it highly suitable for thermoforming, allowing easy shaping into thin-walled, lightweight products. Injection molding benefits from polystyrene's rigidity and clarity, enabling precise, detailed components with smooth finishes. Its cost-effectiveness and ease of recycling further enhance its material suitability for diverse manufacturing processes.

Process Comparison: Thermoforming and Injection Molding

Thermoforming of polystyrene involves heating a sheet until pliable, then molding it over a form to create large, thin-walled products, making it ideal for packaging and trays with moderate detail. Injection molding requires melting polystyrene pellets and injecting the molten material into a precise mold cavity, enabling high-volume production of complex, high-strength parts with tight tolerances. The thermoforming process offers faster cycle times and lower tooling costs, while injection molding excels in dimensional accuracy and product uniformity for small, intricate components.

Design Flexibility with Polystyrene

Thermoforming offers greater design flexibility with polystyrene by enabling the production of large, complex shapes and varying wall thicknesses without the need for expensive molds. Injection molding provides high precision and allows for intricate detail and tight tolerances in polystyrene parts, ideal for mass production of consistent components. Both processes leverage polystyrene's versatility but cater to different design requirements based on complexity and production volume.

Cost Analysis: Tooling and Production

Thermoforming polystyrene involves lower initial tooling costs due to simpler molds, making it cost-effective for small to medium production runs, whereas injection molding requires higher upfront investment in complex, durable molds suitable for high-volume manufacturing. Production costs in thermoforming are generally lower per unit for limited quantities, but injection molding offers better per-unit cost efficiency at scale due to faster cycle times and reduced material waste. Choosing between these processes depends on balancing the initial tooling expense against long-term production volume and desired unit cost.

Production Speed and Scalability

Thermoforming polystyrene offers faster production speeds for large, flat, or thin-walled parts, making it ideal for high-volume, cost-effective runs. Injection molding enables greater scalability for complex, high-detail polystyrene components with consistent quality, albeit at longer cycle times. Manufacturers choose thermoforming for rapid output and injection molding for precise, scalable mass production of polystyrene products.

Surface Finish and Detail Capabilities

Thermoforming polystyrene produces parts with a smooth surface finish ideal for visual appeal but offers limited detail resolution due to material stretching during forming. Injection molding enables high precision and intricate detail reproduction with sharp edges and fine features, supported by polystyrene's excellent flow characteristics. Surface finish quality in injection molding can be tailored through mold texture, surpassing thermoforming in achieving complex geometries and detailed textures.

Environmental Impact and Material Waste

Thermoforming polystyrene generates less material waste compared to injection molding due to its sheet-based process, which allows excess trim to be recycled efficiently. Injection molding typically results in higher scrap rates from runners and sprues, increasing environmental impact through additional raw material consumption and energy use. Both methods can incorporate recycled polystyrene, but thermoforming's lower energy requirements and waste production make it a more environmentally friendly option.

Selecting the Right Method for Polystyrene Products

Thermoforming offers cost-effective production for large, thin-walled polystyrene items with faster tooling and lower initial investment compared to injection molding. Injection molding provides superior precision and structural integrity for complex, high-volume polystyrene components, benefiting industries requiring detailed features and consistent quality. Selecting the right method depends on product design complexity, volume requirements, and budget constraints specific to polystyrene manufacturing.

Thermoforming vs Injection Molding (Polystyrene) Infographic

materialdif.com

materialdif.com