Polystyrene density testing measures the mass per unit volume to determine the material's compactness and consistency, directly affecting its insulation and structural properties. Polystyrene impact testing evaluates the material's ability to absorb energy and resist fracture under sudden force, crucial for packaging and protective applications. Comparing these tests helps manufacturers optimize polystyrene formulations for specific performance requirements.

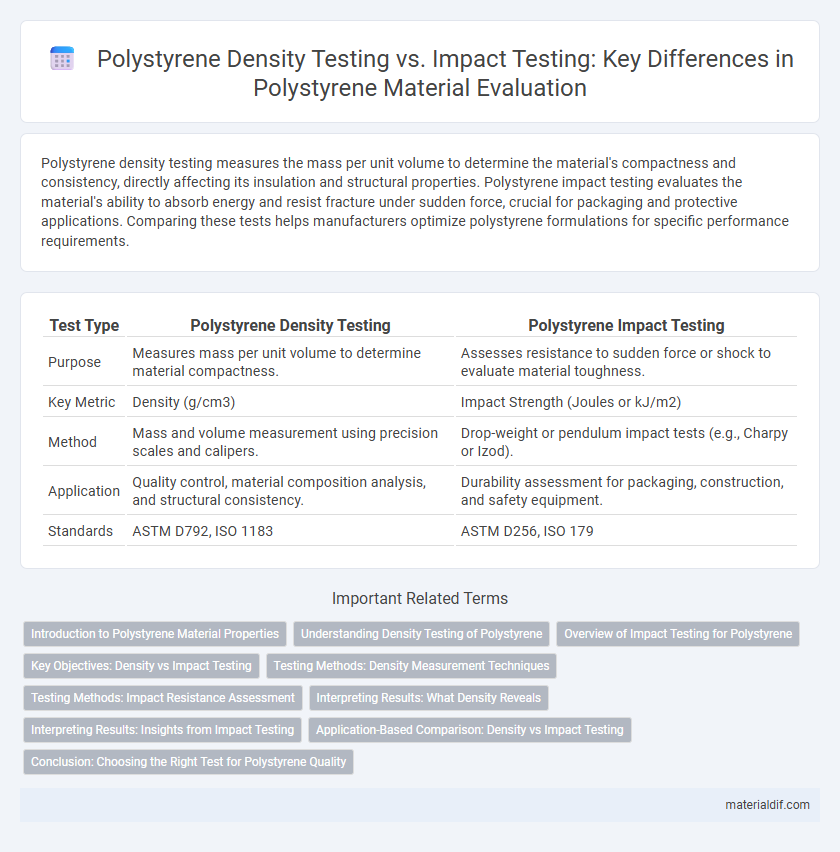

Table of Comparison

| Test Type | Polystyrene Density Testing | Polystyrene Impact Testing |

|---|---|---|

| Purpose | Measures mass per unit volume to determine material compactness. | Assesses resistance to sudden force or shock to evaluate material toughness. |

| Key Metric | Density (g/cm3) | Impact Strength (Joules or kJ/m2) |

| Method | Mass and volume measurement using precision scales and calipers. | Drop-weight or pendulum impact tests (e.g., Charpy or Izod). |

| Application | Quality control, material composition analysis, and structural consistency. | Durability assessment for packaging, construction, and safety equipment. |

| Standards | ASTM D792, ISO 1183 | ASTM D256, ISO 179 |

Introduction to Polystyrene Material Properties

Polystyrene density testing measures the material's mass per unit volume, providing critical data on its structural consistency and suitability for specific applications. Impact testing evaluates polystyrene's resistance to sudden forces, revealing its toughness and fracture characteristics under stress. Understanding both density and impact properties is essential for optimizing polystyrene in packaging, insulation, and consumer product manufacturing.

Understanding Density Testing of Polystyrene

Density testing of polystyrene measures the mass per unit volume, providing critical data on material uniformity, structural integrity, and thermal insulation properties. This test involves precise measurement techniques like displacement or pycnometry to ensure accurate determination of density, which directly influences the foam's strength and buoyancy. Understanding density testing allows manufacturers to control quality and optimize performance parameters, distinguishing it from impact testing that evaluates the material's resistance to sudden forces.

Overview of Impact Testing for Polystyrene

Impact testing for polystyrene evaluates the material's resistance to sudden forces or shocks, crucial for applications requiring durability and toughness. Common methods include the Izod and Charpy impact tests, which measure energy absorbed during fracture to determine impact strength. This testing assesses the material's behavior under real-world conditions, differentiating it from density testing that primarily measures mass per unit volume.

Key Objectives: Density vs Impact Testing

Polystyrene density testing primarily aims to measure the material's mass per unit volume, which directly influences its insulation properties, rigidity, and overall quality control. In contrast, polystyrene impact testing evaluates the polymer's ability to absorb energy and resist fracture under sudden force, reflecting its durability and performance under mechanical stress. These tests address distinct material characteristics: density testing ensures consistency and structural integrity, while impact testing assesses toughness and suitability for protective applications.

Testing Methods: Density Measurement Techniques

Polystyrene density testing primarily utilizes methods such as the water displacement technique, gas pycnometry, and ultrasonics to measure material compactness and void content accurately. In contrast, impact testing focuses on the material's resistance to force or shock, typically using pendulum impact testers or drop-weight impact testing equipment, which do not directly measure density. Density measurement techniques for polystyrene provide critical data on bulk properties essential for quality control and product consistency in applications like packaging and insulation.

Testing Methods: Impact Resistance Assessment

Polystyrene impact testing evaluates the material's ability to withstand sudden forces by measuring its resistance to fracture under specified impact loads, often using methods such as the Izod or Charpy test. In contrast, polystyrene density testing determines mass per unit volume to infer material uniformity but does not directly assess mechanical performance. Impact resistance assessment relies on controlled impact test setups that quantify energy absorption and failure characteristics, crucial for applications demanding high durability and toughness.

Interpreting Results: What Density Reveals

Polystyrene density testing measures the material's mass per unit volume, revealing crucial information about its structural uniformity and potential insulation properties. Interpreting density results helps predict performance characteristics such as thermal resistance and mechanical strength, essential for quality control. In contrast, impact testing assesses the material's ability to absorb energy and resist fracture, complementing density data to provide a comprehensive evaluation of polystyrene durability.

Interpreting Results: Insights from Impact Testing

Impact testing of polystyrene provides critical insights into its toughness and ability to absorb energy under sudden force, revealing performance limitations in real-world applications. Unlike density testing, which measures mass per unit volume, impact testing highlights the material's resistance to cracking and deformation, essential for evaluating durability. Understanding impact test results enables engineers to optimize formulations for enhanced mechanical strength and resilience in various polystyrene products.

Application-Based Comparison: Density vs Impact Testing

Polystyrene density testing measures material compactness, critical for applications requiring precise weight and insulation properties, such as packaging and thermal insulation panels. In contrast, polystyrene impact testing evaluates resistance to sudden forces, essential for applications in protective gear and structural components exposed to mechanical stress. Selecting between density and impact testing depends on whether the application prioritizes lightweight performance or durability under impact conditions.

Conclusion: Choosing the Right Test for Polystyrene Quality

Polystyrene density testing provides precise measurements of material consistency, essential for ensuring uniformity in applications requiring specific weight and volume standards. Polystyrene impact testing evaluates the material's resistance to sudden force, crucial for assessing durability and performance under stress. Selecting the right test depends on whether the priority is structural integrity or physical robustness, guiding manufacturers to optimize polystyrene quality for targeted end-use requirements.

Polystyrene Density Testing vs Polystyrene Impact Testing Infographic

materialdif.com

materialdif.com