Crystal Polystyrene offers excellent transparency and rigidity, making it ideal for applications requiring clear, glass-like appearance, such as display cases and cosmetic packaging. High Impact Polystyrene (HIPS) provides superior impact resistance and durability, which enhances protection in more demanding environments like food trays and appliance housings. Choosing between the two depends on the need for clarity versus toughness in the final product.

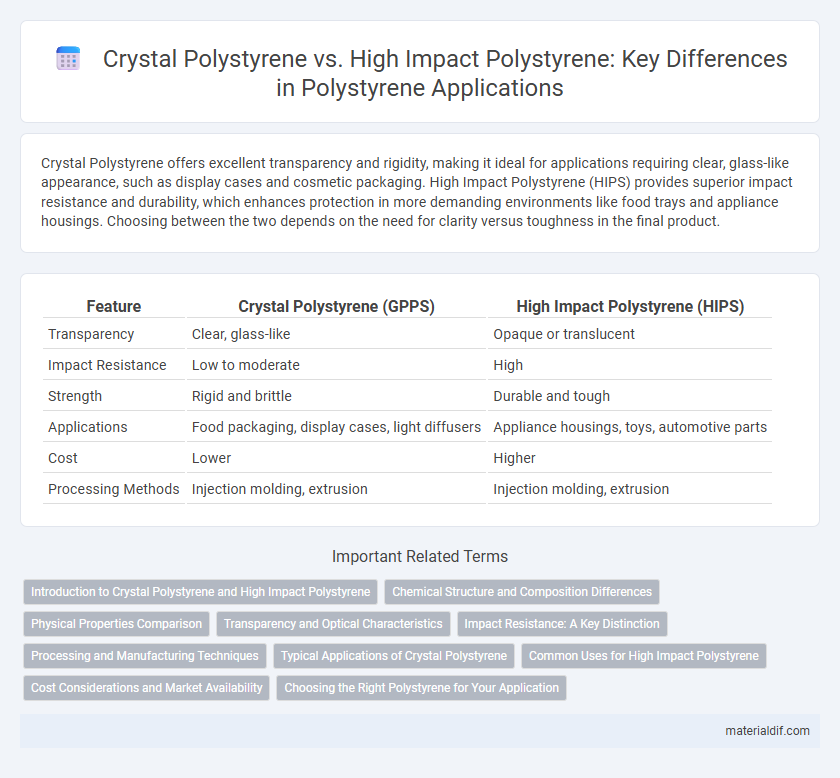

Table of Comparison

| Feature | Crystal Polystyrene (GPPS) | High Impact Polystyrene (HIPS) |

|---|---|---|

| Transparency | Clear, glass-like | Opaque or translucent |

| Impact Resistance | Low to moderate | High |

| Strength | Rigid and brittle | Durable and tough |

| Applications | Food packaging, display cases, light diffusers | Appliance housings, toys, automotive parts |

| Cost | Lower | Higher |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion |

Introduction to Crystal Polystyrene and High Impact Polystyrene

Crystal Polystyrene (GPPS) is a transparent, rigid polymer known for its clarity and ease of fabrication, commonly used in packaging and display applications. High Impact Polystyrene (HIPS) incorporates rubber modifiers, enhancing its impact resistance and toughness while maintaining good processability, making it ideal for appliances and automotive parts. Both materials originate from the polystyrene family but differ significantly in mechanical properties due to their structural formulations.

Chemical Structure and Composition Differences

Crystal Polystyrene (GPPS) is a transparent, rigid polymer with a simple chemical structure consisting solely of styrene monomers, providing clarity and stiffness but limited impact resistance. High Impact Polystyrene (HIPS) incorporates polybutadiene rubber particles grafted onto the styrene matrix, resulting in a heterogeneous composition that enhances toughness and impact strength through energy absorption mechanisms. The rubber phase in HIPS disrupts the otherwise brittle polystyrene chains, creating a two-phase system that balances rigidity with improved mechanical durability.

Physical Properties Comparison

Crystal Polystyrene (GPPS) offers a rigid structure with excellent clarity and stiffness, making it ideal for applications requiring transparency and dimensional stability. High Impact Polystyrene (HIPS) incorporates rubber additives, enhancing impact resistance and toughness at the cost of reduced clarity and rigidity. The density of GPPS typically ranges around 1.04 g/cm3, while HIPS is slightly lower, offering improved durability for impact-prone environments.

Transparency and Optical Characteristics

Crystal Polystyrene (GPPS) offers superior transparency and excellent optical clarity, making it ideal for applications requiring high light transmission and visual appeal. High Impact Polystyrene (HIPS) has a more opaque appearance with lower transparency due to its rubber-modified composition, which enhances impact resistance but reduces optical clarity. The distinct differences in polymer structure directly influence the optical characteristics, with GPPS favored for clear packaging and displays, while HIPS is chosen for durable, impact-resistant products.

Impact Resistance: A Key Distinction

Crystal Polystyrene (GPPS) offers excellent clarity and rigidity but has lower impact resistance compared to High Impact Polystyrene (HIPS), which is engineered with rubber additives to enhance toughness. HIPS displays superior ability to absorb shocks and resist cracking, making it ideal for applications requiring durability under mechanical stress. This impact resistance difference is crucial when selecting materials for packaging, automotive parts, and consumer goods.

Processing and Manufacturing Techniques

Crystal Polystyrene (GPPS) is processed mainly through injection molding and extrusion, favored for its clarity and ease of thermoforming, enabling precise, detailed shapes in packaging and disposable items. High Impact Polystyrene (HIPS) incorporates rubber particles, requiring specialized mixing and compounding techniques during extrusion or injection molding to achieve enhanced toughness and impact resistance. Manufacturing HIPS demands controlled dispersion of rubber within the polystyrene matrix to balance strength with processability, whereas GPPS benefits from simpler processing due to its homogenous, rigid structure.

Typical Applications of Crystal Polystyrene

Crystal polystyrene is widely used in packaging applications such as clear containers, cosmetic jars, and food packaging due to its excellent transparency and rigidity. It is commonly found in disposable cutlery, laboratory ware, and display cases where visual clarity and aesthetic appeal are essential. Its brittleness limits its use in impact-resistant products, making it ideal for applications prioritizing appearance over durability.

Common Uses for High Impact Polystyrene

High Impact Polystyrene (HIPS) is widely used in packaging, automotive parts, and consumer electronics due to its enhanced toughness and impact resistance compared to Crystal Polystyrene. It is commonly found in refrigerator liners, food containers, and disposable cutlery, benefiting from its durability and ease of thermoforming. The material's balance of rigidity and impact strength makes it suitable for various everyday applications where strength and cost-effectiveness are required.

Cost Considerations and Market Availability

Crystal Polystyrene typically costs less than High Impact Polystyrene due to its simpler manufacturing process and lower material demands. High Impact Polystyrene, while more expensive, offers enhanced durability and impact resistance, justifying its higher price in applications needing toughness. Crystal Polystyrene enjoys broader market availability for general packaging and display purposes, whereas High Impact Polystyrene is more specialized and may have limited suppliers depending on regional demand.

Choosing the Right Polystyrene for Your Application

Crystal Polystyrene offers excellent clarity and is ideal for applications requiring transparency, such as display cases and food packaging, due to its smooth surface and ease of printing. High Impact Polystyrene contains rubber additives that enhance toughness and impact resistance, making it suitable for durable products like appliance housings and automotive parts. Selecting the right type depends on whether optical clarity or mechanical strength is the primary requirement for your specific application.

Crystal Polystyrene vs High Impact Polystyrene Infographic

materialdif.com

materialdif.com