Thermoforming involves heating a polystyrene sheet until pliable, then shaping it over a mold to create detailed, thin-walled PET products ideal for packaging. Blow molding, by contrast, inflates molten polystyrene inside a mold to form hollow PET containers, such as bottles, with uniform wall thickness and enhanced strength. Choosing between thermoforming and blow molding depends on the desired PET product's shape, thickness, and application requirements.

Table of Comparison

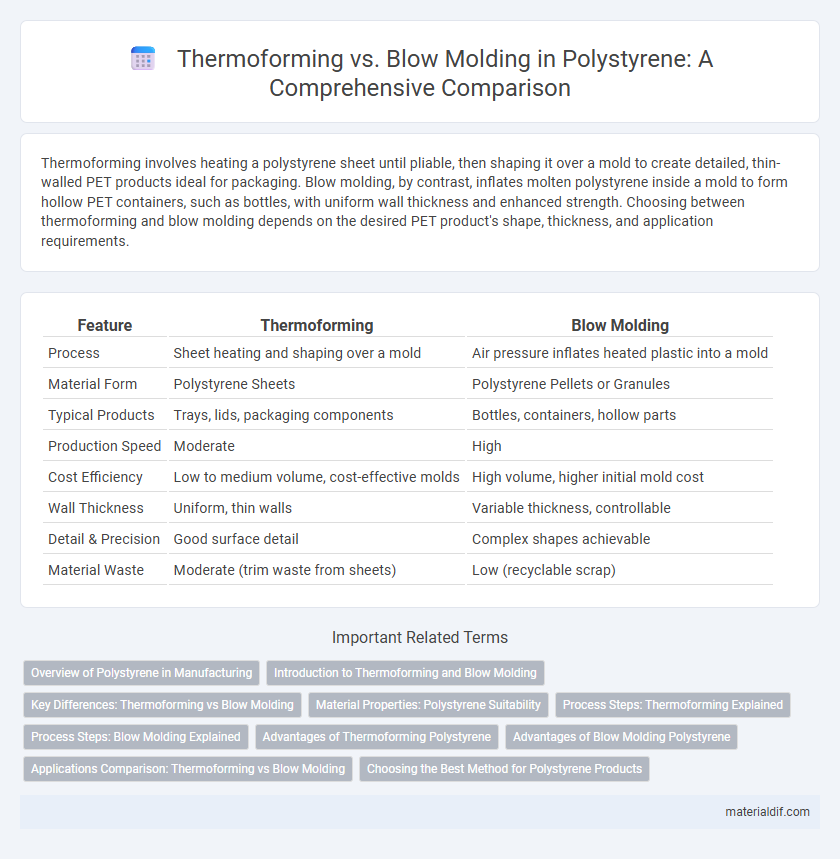

| Feature | Thermoforming | Blow Molding |

|---|---|---|

| Process | Sheet heating and shaping over a mold | Air pressure inflates heated plastic into a mold |

| Material Form | Polystyrene Sheets | Polystyrene Pellets or Granules |

| Typical Products | Trays, lids, packaging components | Bottles, containers, hollow parts |

| Production Speed | Moderate | High |

| Cost Efficiency | Low to medium volume, cost-effective molds | High volume, higher initial mold cost |

| Wall Thickness | Uniform, thin walls | Variable thickness, controllable |

| Detail & Precision | Good surface detail | Complex shapes achievable |

| Material Waste | Moderate (trim waste from sheets) | Low (recyclable scrap) |

Overview of Polystyrene in Manufacturing

Polystyrene is widely used in both thermoforming and blow molding processes due to its ease of molding and cost-effectiveness. Thermoforming involves heating polystyrene sheets until pliable, then shaping them in molds, making it ideal for producing rigid, detailed packaging like trays and containers. Blow molding, by injecting air into molten polystyrene to form hollow shapes, is commonly used for creating lightweight bottles and large hollow products, offering rapid production and material efficiency.

Introduction to Thermoforming and Blow Molding

Thermoforming shapes heated polystyrene sheets by vacuum or pressure into molds, ideal for producing lightweight, detailed packaging and trays. Blow molding inflates heated polystyrene parisons into hollow molds, suitable for manufacturing containers and bottles with consistent wall thickness. Both methods leverage polystyrene's thermoplastic properties but differ in forming techniques and product applications.

Key Differences: Thermoforming vs Blow Molding

Thermoforming shapes heated polystyrene sheets over molds to create flat or shallow products, ideal for packaging and trays. Blow molding uses air pressure to inflate heated polystyrene into hollow shapes, producing containers like bottles with uniform wall thickness. Key differences include thermoforming's reliance on sheet material and open molds versus blow molding's use of parisons and closed molds for complex, hollow designs.

Material Properties: Polystyrene Suitability

Polystyrene's rigid and lightweight nature makes it highly suitable for thermoforming, which requires materials that can soften uniformly and retain shape upon cooling, ideal for packaging trays and disposable containers. In contrast, blow molding demands materials with high ductility and impact resistance, properties where polystyrene's brittleness limits its effectiveness, often leading to cracks or deformations under stress. Therefore, polystyrene is predominantly favorable for thermoforming applications due to its excellent dimensional stability and ease of moldability, whereas its use in blow molding remains limited.

Process Steps: Thermoforming Explained

Thermoforming involves heating a polystyrene sheet until pliable, then shaping it over a mold using vacuum or pressure to create detailed, lightweight forms. The process begins with clamping the heated sheet, followed by stretching it over the mold surface, and finally cooling it to retain the shape. This method offers precise control over wall thickness and is ideal for producing thin, high-quality parts like trays and packaging components.

Process Steps: Blow Molding Explained

Blow molding of polystyrene involves melting the plastic into a parison, which is then clamped into a mold. Compressed air is blown into the parison, inflating it to conform to the mold's interior shape. This process is ideal for producing hollow, lightweight items such as containers and bottles with uniform wall thickness.

Advantages of Thermoforming Polystyrene

Thermoforming polystyrene offers precise control over wall thickness and complex shapes, making it ideal for custom packaging and product trays. This process provides faster turnaround times and lower tooling costs compared to blow molding, enhancing cost efficiency for small to medium production runs. Enhanced surface finish and design flexibility further distinguish thermoforming as a superior choice for high-quality polystyrene products.

Advantages of Blow Molding Polystyrene

Blow molding polystyrene offers superior design flexibility, enabling the production of hollow, complex shapes with uniform wall thickness that are difficult to achieve through thermoforming. The process provides enhanced structural integrity and airtight seals, making it ideal for packaging applications such as containers and bottles. Additionally, blow molding reduces material waste and shortens cycle times, increasing manufacturing efficiency compared to thermoforming.

Applications Comparison: Thermoforming vs Blow Molding

Thermoforming of polystyrene is widely used for creating thin-walled packaging such as trays, blisters, and disposable cups, offering excellent detail and surface finish for retail and food industry applications. Blow molding, on the other hand, is preferred for manufacturing hollow polystyrene products like bottles, containers, and large-capacity tanks, providing superior strength and uniform wall thickness essential for liquid storage and consumer goods. The choice between thermoforming and blow molding depends heavily on product shape complexity, required durability, and production volume.

Choosing the Best Method for Polystyrene Products

Thermoforming offers precise control over shape and thickness, making it ideal for polystyrene packaging and trays requiring detailed design and surface finish. Blow molding excels in producing hollow polystyrene products like containers and bottles with uniform wall thickness and high structural integrity. Selecting the best method depends on product complexity, wall thickness requirements, and production volume, with thermoforming preferred for detailed flat parts and blow molding suited for containers with three-dimensional shapes.

Thermoforming vs Blow molding Infographic

materialdif.com

materialdif.com