Flame retardant polystyrene contains additives that significantly reduce its flammability compared to standard polystyrene, making it safer for use in applications where fire resistance is critical. This enhanced material maintains similar lightweight and insulation properties while providing improved safety standards. In contrast, standard polystyrene is more susceptible to ignition and rapid flame spread, limiting its use in fire-sensitive environments.

Table of Comparison

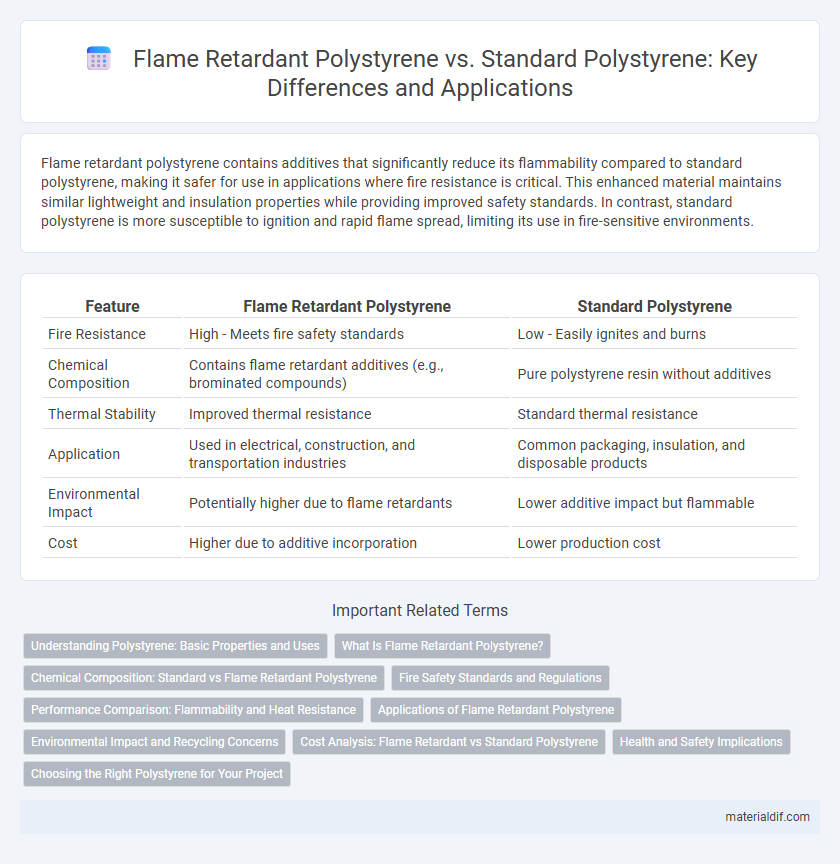

| Feature | Flame Retardant Polystyrene | Standard Polystyrene |

|---|---|---|

| Fire Resistance | High - Meets fire safety standards | Low - Easily ignites and burns |

| Chemical Composition | Contains flame retardant additives (e.g., brominated compounds) | Pure polystyrene resin without additives |

| Thermal Stability | Improved thermal resistance | Standard thermal resistance |

| Application | Used in electrical, construction, and transportation industries | Common packaging, insulation, and disposable products |

| Environmental Impact | Potentially higher due to flame retardants | Lower additive impact but flammable |

| Cost | Higher due to additive incorporation | Lower production cost |

Understanding Polystyrene: Basic Properties and Uses

Flame retardant polystyrene incorporates chemical additives that enhance its resistance to ignition and slow down the spread of fire, making it essential for applications requiring improved safety standards. Standard polystyrene, characterized by its lightweight, rigidity, and insulating properties, is widely used in packaging, disposable containers, and insulation materials. Understanding the basic properties of both types is crucial for selecting the appropriate material for industries such as construction, electronics, and automotive manufacturing.

What Is Flame Retardant Polystyrene?

Flame retardant polystyrene is a chemically modified variant of standard polystyrene that incorporates flame-retardant additives to inhibit ignition and slow the spread of fire. These additives, such as brominated compounds or phosphorus-based chemicals, improve the material's fire resistance without significantly compromising its mechanical properties. This enhanced safety feature makes flame retardant polystyrene ideal for applications requiring strict fire safety standards, including electronics housings and building materials.

Chemical Composition: Standard vs Flame Retardant Polystyrene

Flame retardant polystyrene is chemically modified with the incorporation of halogenated compounds or phosphorus-based additives to inhibit combustion, unlike standard polystyrene which consists primarily of styrene monomers without such fire-resistant elements. These flame retardant additives alter the polymer matrix, enhancing thermal stability and reducing flammability by promoting char formation and interrupting radical propagation during combustion. The inclusion of these specialized compounds in flame retardant polystyrene significantly improves its fire performance compared to the inherently flammable standard polystyrene.

Fire Safety Standards and Regulations

Flame retardant polystyrene incorporates chemical additives that significantly reduce its flammability, enabling compliance with stringent fire safety standards such as UL 94 V-0 and ASTM E84. Standard polystyrene lacks these fire retardant properties, making it more susceptible to ignition and rapid fire spread, which often disqualifies it from use in regulated environments requiring enhanced fire protection. Regulatory bodies like NFPA and building codes mandate the use of flame retardant materials in construction and electronics, emphasizing the critical role of fire retardant polystyrene in meeting these fire safety regulations.

Performance Comparison: Flammability and Heat Resistance

Flame retardant polystyrene significantly reduces flammability by incorporating additives such as brominated compounds, which slow ignition and self-extinguish flames, compared to standard polystyrene's high combustibility. Heat resistance in flame retardant polystyrene improves thermal stability, maintaining structural integrity at temperatures up to 80-100degC, whereas standard polystyrene typically softens around 70degC. This enhanced performance makes flame retardant polystyrene ideal for applications requiring stringent fire safety standards.

Applications of Flame Retardant Polystyrene

Flame retardant polystyrene is widely used in electronic housings, automotive components, and construction materials where enhanced fire safety standards are critical. Its applications extend to insulation panels, lighting fixtures, and appliance casings, providing improved resistance to ignition and slow burning properties compared to standard polystyrene. This material is essential in public transportation interiors and electrical enclosures to meet strict fire regulations and ensure occupant safety.

Environmental Impact and Recycling Concerns

Flame retardant polystyrene contains added chemical compounds such as brominated flame retardants, which pose significant environmental hazards due to their persistence and potential for bioaccumulation in ecosystems. In contrast, standard polystyrene, while still challenging to recycle, lacks these toxic additives, reducing its overall environmental toxicity. Recycling processes for flame retardant polystyrene are further complicated as the presence of flame retardants can contaminate recycling streams, leading to increased costs and potential restrictions in reuse applications.

Cost Analysis: Flame Retardant vs Standard Polystyrene

Flame retardant polystyrene typically costs 20-40% more than standard polystyrene due to the inclusion of specialized additives such as brominated or phosphorus-based compounds that enhance fire resistance. While flame retardant variants incur higher initial material expenses, their use can reduce overall costs in applications with stringent fire safety regulations by potentially lowering insurance premiums and compliance fees. Standard polystyrene remains more cost-effective for non-critical environments but may lead to higher long-term expenses if fire safety retrofitting or liability risks arise.

Health and Safety Implications

Flame retardant polystyrene incorporates chemical additives that reduce flammability, significantly lowering fire hazards compared to standard polystyrene. However, these additives may release toxic fumes such as brominated compounds during combustion, posing health risks upon exposure. Standard polystyrene lacks this fire resistance, increasing fire-related dangers but generally produces fewer harmful emissions under normal conditions.

Choosing the Right Polystyrene for Your Project

Flame retardant polystyrene incorporates chemical additives like brominated compounds or phosphorus-based agents to reduce flammability, making it essential for applications requiring enhanced fire safety standards such as electrical enclosures or building insulation. Standard polystyrene, valued for its lightweight and insulating properties, is ideal for packaging, disposable containers, and craft materials where fire resistance is not critical. Selecting the appropriate type depends on regulatory compliance, intended use environment, and specific safety requirements to ensure optimal performance and protection.

Flame Retardant Polystyrene vs Standard Polystyrene Infographic

materialdif.com

materialdif.com