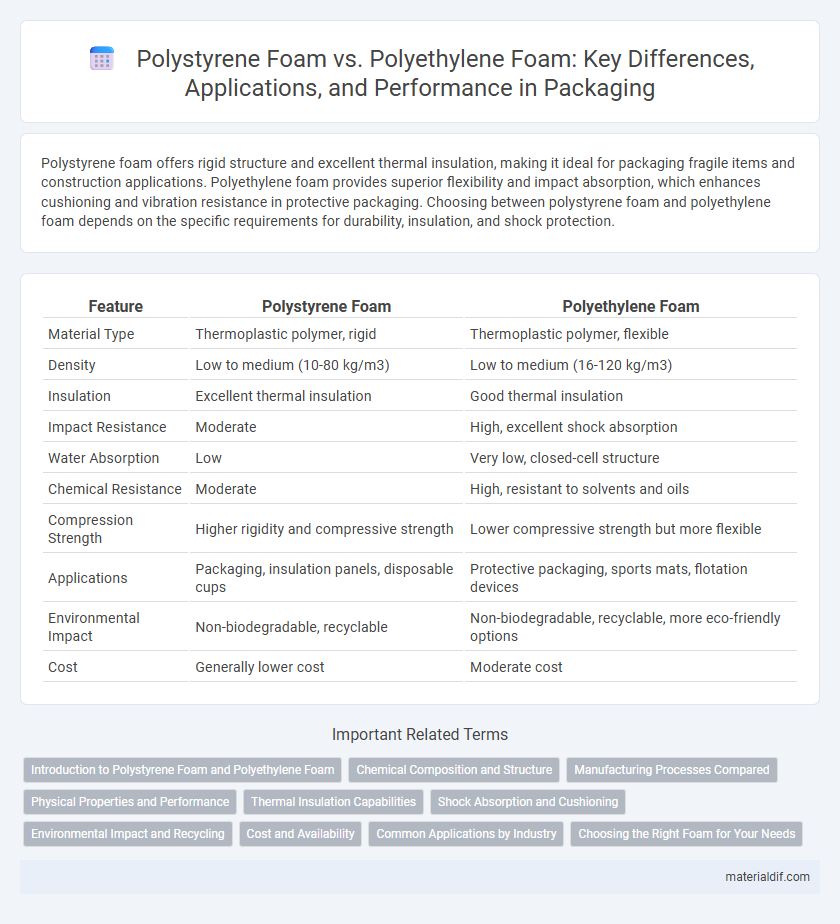

Polystyrene foam offers rigid structure and excellent thermal insulation, making it ideal for packaging fragile items and construction applications. Polyethylene foam provides superior flexibility and impact absorption, which enhances cushioning and vibration resistance in protective packaging. Choosing between polystyrene foam and polyethylene foam depends on the specific requirements for durability, insulation, and shock protection.

Table of Comparison

| Feature | Polystyrene Foam | Polyethylene Foam |

|---|---|---|

| Material Type | Thermoplastic polymer, rigid | Thermoplastic polymer, flexible |

| Density | Low to medium (10-80 kg/m3) | Low to medium (16-120 kg/m3) |

| Insulation | Excellent thermal insulation | Good thermal insulation |

| Impact Resistance | Moderate | High, excellent shock absorption |

| Water Absorption | Low | Very low, closed-cell structure |

| Chemical Resistance | Moderate | High, resistant to solvents and oils |

| Compression Strength | Higher rigidity and compressive strength | Lower compressive strength but more flexible |

| Applications | Packaging, insulation panels, disposable cups | Protective packaging, sports mats, flotation devices |

| Environmental Impact | Non-biodegradable, recyclable | Non-biodegradable, recyclable, more eco-friendly options |

| Cost | Generally lower cost | Moderate cost |

Introduction to Polystyrene Foam and Polyethylene Foam

Polystyrene foam is a rigid, lightweight material commonly used for insulation, packaging, and craft applications due to its excellent thermal resistance and structural strength. Polyethylene foam, by contrast, is a flexible, durable cushioning material favored for impact absorption and vibration dampening in packaging and sports equipment. Both foams offer distinct properties tailored to specific industrial and commercial uses, emphasizing the importance of material selection based on application requirements.

Chemical Composition and Structure

Polystyrene foam is composed of styrene monomers polymerized to form a rigid, aromatic hydrocarbon polymer characterized by a benzene ring in its structure, providing a stiff and brittle texture. Polyethylene foam consists of long chains of ethylene monomers producing a saturated hydrocarbon polymer with flexible, non-aromatic chains, which results in a soft, elastic material. The difference in chemical composition and molecular structure directly influences their thermal insulation properties and mechanical strength, with polystyrene foam being more rigid and polyethylene foam more cushioning.

Manufacturing Processes Compared

Polystyrene foam is produced through a polymerization process involving the expansion of polystyrene beads via steam activation, creating a rigid, closed-cell structure ideal for insulation and packaging. Polyethylene foam manufacturing relies on extrusion or molding with chemical or physical blowing agents, resulting in a flexible, open-cell or closed-cell foam with excellent cushioning and shock absorption properties. The contrast in production methods directly influences their density, resilience, and typical applications across thermal insulation, packaging, and impact protection industries.

Physical Properties and Performance

Polystyrene foam offers higher rigidity and excellent thermal insulation with a closed-cell structure, making it ideal for applications requiring structural support and temperature resistance. Polyethylene foam provides superior flexibility, impact absorption, and moisture resistance due to its open-cell, low-density composition. The choice between polystyrene and polyethylene foam depends on specific requirements such as load-bearing capacity, cushioning effect, and environmental exposure.

Thermal Insulation Capabilities

Polystyrene foam offers superior thermal insulation capabilities compared to polyethylene foam, with a lower thermal conductivity ranging from 0.03 to 0.04 W/m*K. Its closed-cell structure provides excellent resistance to heat transfer, making it ideal for applications requiring consistent temperature control. Polyethylene foam, while flexible and resilient, typically exhibits higher thermal conductivity around 0.04 to 0.06 W/m*K, resulting in less effective insulation performance.

Shock Absorption and Cushioning

Polystyrene foam offers high rigidity and excellent shock absorption, making it ideal for packaging fragile items, while polyethylene foam provides superior cushioning due to its flexible and resilient nature. Polyethylene foam's closed-cell structure enhances impact resistance and energy absorption, offering better protection against repeated shocks compared to the more brittle polystyrene foam. When selecting foam materials for shock absorption and cushioning, the specific application requirements such as weight, durability, and impact frequency determine the optimal choice between polystyrene and polyethylene foams.

Environmental Impact and Recycling

Polystyrene foam, widely used in packaging and insulation, poses significant environmental challenges due to its non-biodegradable nature and limited recycling options, often leading to persistent landfill accumulation. Polyethylene foam, while also challenging to recycle, generally presents a lower environmental impact because it is more easily processed and reused in closed-loop recycling systems. Both materials require advanced recycling infrastructure to mitigate their ecological footprint, with polyethylene foam currently offering a more sustainable pathway for reuse and waste reduction.

Cost and Availability

Polystyrene foam generally offers a lower cost compared to polyethylene foam, making it a more budget-friendly option for a wide range of applications. It is widely available in both expanded (EPS) and extruded (XPS) forms, ensuring easy access through numerous suppliers and manufacturers. Polyethylene foam tends to be more expensive due to its enhanced durability and flexibility, with availability often dependent on specialized distributors.

Common Applications by Industry

Polystyrene foam is widely used in the packaging industry for insulation and protective cushioning of fragile goods, including electronics and food containers. Polyethylene foam finds common applications in automotive and sports equipment sectors due to its durability and impact absorption properties. Both foams serve key roles in construction, with polystyrene foam used for thermal insulation and polyethylene foam applied as a vapor barrier and cushioning material.

Choosing the Right Foam for Your Needs

Polystyrene foam offers excellent rigidity, insulation, and moisture resistance, making it ideal for packaging, insulation panels, and craft applications where structural support is crucial. Polyethylene foam provides superior flexibility, cushioning, and impact absorption, suited for protective packaging, sports equipment, and shock protection. Selecting the right foam depends on specific requirements such as load-bearing strength, durability, and environmental exposure.

Polystyrene Foam vs Polyethylene Foam Infographic

materialdif.com

materialdif.com