Crystal polystyrene offers exceptional clarity and a glass-like appearance, making it ideal for applications requiring a transparent and aesthetically pleasing finish. In contrast, impact polystyrene provides enhanced toughness and resistance to breakage, suited for products that demand durability and impact resistance. Selecting between the two depends on the balance between visual appeal and mechanical strength needed for the specific application.

Table of Comparison

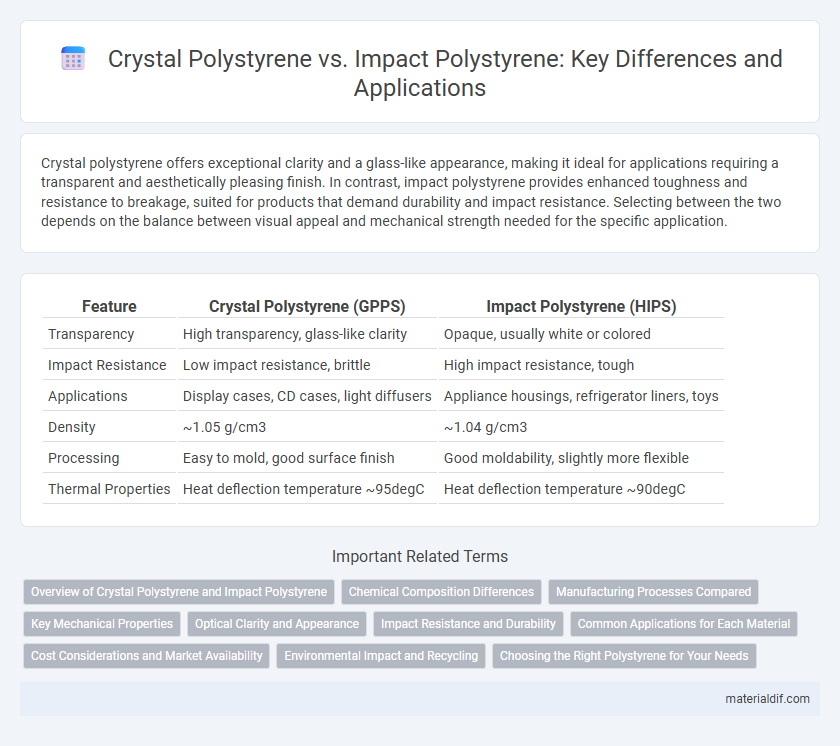

| Feature | Crystal Polystyrene (GPPS) | Impact Polystyrene (HIPS) |

|---|---|---|

| Transparency | High transparency, glass-like clarity | Opaque, usually white or colored |

| Impact Resistance | Low impact resistance, brittle | High impact resistance, tough |

| Applications | Display cases, CD cases, light diffusers | Appliance housings, refrigerator liners, toys |

| Density | ~1.05 g/cm3 | ~1.04 g/cm3 |

| Processing | Easy to mold, good surface finish | Good moldability, slightly more flexible |

| Thermal Properties | Heat deflection temperature ~95degC | Heat deflection temperature ~90degC |

Overview of Crystal Polystyrene and Impact Polystyrene

Crystal polystyrene is a rigid, transparent polymer known for its excellent clarity and smooth surface finish, making it ideal for applications such as packaging and optical devices. Impact polystyrene, modified with rubber additives, offers enhanced toughness and impact resistance while maintaining good processability, commonly used in automotive parts and household appliances. Both types differ significantly in mechanical properties, with crystal polystyrene favoring aesthetics and rigidity, and impact polystyrene prioritizing durability and resistance to breakage.

Chemical Composition Differences

Crystal polystyrene, also known as general-purpose polystyrene (GPPS), consists of a pure polystyrene matrix with minimal additives, resulting in its transparent and brittle nature. Impact polystyrene (HIPS) incorporates rubbery polybutadiene particles dispersed within the polystyrene matrix, enhancing its toughness and impact resistance due to the rubber phase. The key chemical difference lies in the copolymerization and blending process, where impact polystyrene's rubber component modifies the polymer morphology and mechanical properties compared to the homopolymer structure of crystal polystyrene.

Manufacturing Processes Compared

Crystal polystyrene is produced through suspension polymerization, resulting in a transparent and rigid material ideal for applications requiring optical clarity. Impact polystyrene undergoes an additional rubber graft copolymerization process, incorporating polybutadiene rubber to improve toughness and impact resistance. The manufacturing complexity of impact polystyrene enhances its mechanical properties, differentiating it from the more brittle, visually clear crystal polystyrene.

Key Mechanical Properties

Crystal polystyrene exhibits high rigidity and excellent dimensional stability with a tensile strength typically around 55 MPa, making it suitable for applications requiring clarity and precision. Impact polystyrene, modified with rubber, provides enhanced toughness and impact resistance, often achieving an impact strength exceeding 30 kJ/m2. Differences in elongation at break are significant, with crystal polystyrene showing low flexibility (~2%) compared to the more ductile impact polystyrene (~50%), highlighting their diverse mechanical performance.

Optical Clarity and Appearance

Crystal polystyrene exhibits superior optical clarity with a transparent, glass-like appearance ideal for display packaging and optical lenses. Impact polystyrene incorporates rubber modifiers, enhancing toughness but reducing transparency, resulting in an opaque, matte finish suitable for durable consumer products. The trade-off between optical clarity and impact resistance dictates the choice between these polystyrene types based on application requirements.

Impact Resistance and Durability

Impact polystyrene (HIPS) exhibits significantly higher impact resistance and durability compared to crystal polystyrene due to its rubber-modified polymer structure, which absorbs shocks and resists cracking. Crystal polystyrene, while offering superior clarity and surface finish, is more brittle and prone to fracture under mechanical stress. Therefore, impact polystyrene is preferred for applications requiring toughness and long-term durability, such as packaging and automotive parts.

Common Applications for Each Material

Crystal polystyrene is commonly used in applications requiring clarity and rigidity, such as clear packaging, disposable cutlery, and display cases. Impact polystyrene, known for its enhanced toughness and resistance to impact, is frequently utilized in automotive parts, appliance housings, and protective equipment. Each type's unique mechanical properties determine their suitability for specific industrial and consumer product applications.

Cost Considerations and Market Availability

Crystal polystyrene generally costs less due to its simpler manufacturing process and lower material additives compared to impact polystyrene, which requires rubber or other modifiers to enhance toughness. Market availability favors crystal polystyrene as it is widely produced and used for applications requiring clarity, while impact polystyrene, with its specialized properties, is less common and typically available in smaller quantities. Cost considerations often drive manufacturers toward crystal polystyrene for budget-sensitive projects, whereas impact polystyrene is preferred despite higher prices for applications demanding higher impact resistance.

Environmental Impact and Recycling

Crystal polystyrene, known for its clarity and rigidity, tends to have a lower environmental impact during recycling due to its higher purity and ease of separation from mixed plastics. Impact polystyrene, modified with rubber to increase toughness, poses more challenges in recycling because the rubber content complicates processing and reduces material quality. Both types are recyclable, but recycling facilities prioritize crystal polystyrene to improve efficiency and reduce environmental burden.

Choosing the Right Polystyrene for Your Needs

Crystal polystyrene offers excellent clarity, making it ideal for applications requiring transparency and a smooth finish, such as product packaging and display cases. Impact polystyrene provides enhanced toughness and durability, suitable for products exposed to mechanical stress, including appliance housings and automotive parts. Selecting between crystal and impact polystyrene depends on prioritizing either optical clarity or impact resistance to meet your specific project requirements.

Crystal polystyrene vs Impact polystyrene Infographic

materialdif.com

materialdif.com