Polystyrene insulation offers superior moisture resistance and higher R-values per inch compared to fiberglass insulation, making it ideal for environments prone to dampness. Its rigid structure provides excellent thermal performance and durability, whereas fiberglass tends to compress and lose effectiveness over time. While fiberglass is cost-effective and easier to install, polystyrene delivers long-term energy efficiency and enhanced protection against mold and mildew.

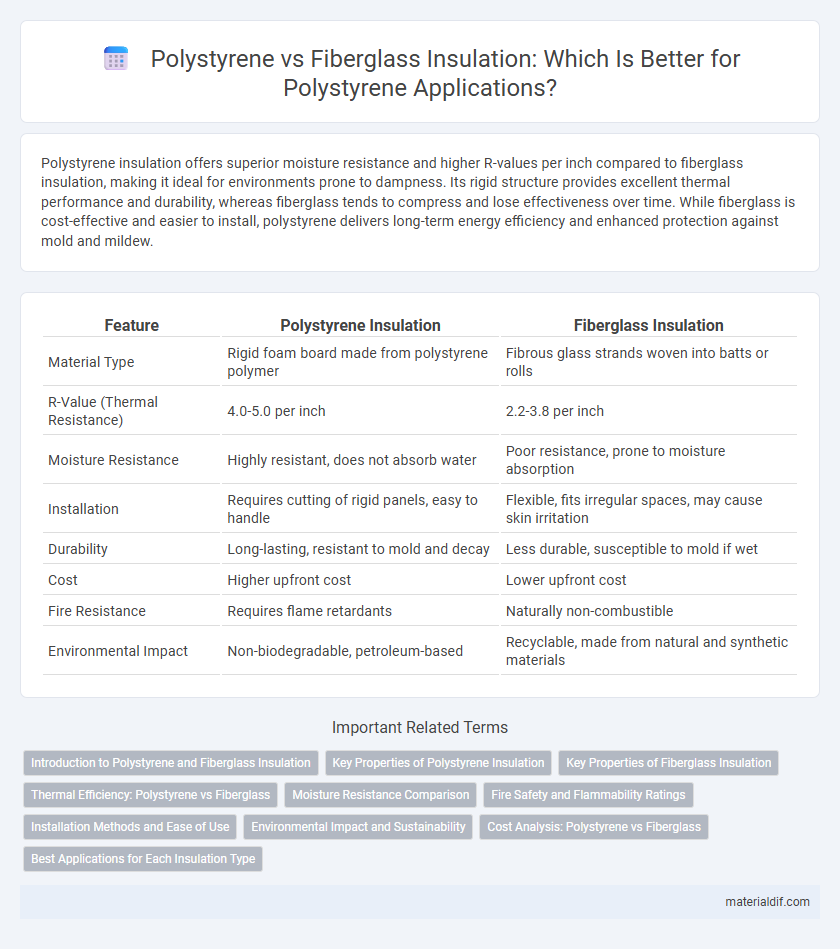

Table of Comparison

| Feature | Polystyrene Insulation | Fiberglass Insulation |

|---|---|---|

| Material Type | Rigid foam board made from polystyrene polymer | Fibrous glass strands woven into batts or rolls |

| R-Value (Thermal Resistance) | 4.0-5.0 per inch | 2.2-3.8 per inch |

| Moisture Resistance | Highly resistant, does not absorb water | Poor resistance, prone to moisture absorption |

| Installation | Requires cutting of rigid panels, easy to handle | Flexible, fits irregular spaces, may cause skin irritation |

| Durability | Long-lasting, resistant to mold and decay | Less durable, susceptible to mold if wet |

| Cost | Higher upfront cost | Lower upfront cost |

| Fire Resistance | Requires flame retardants | Naturally non-combustible |

| Environmental Impact | Non-biodegradable, petroleum-based | Recyclable, made from natural and synthetic materials |

Introduction to Polystyrene and Fiberglass Insulation

Polystyrene insulation, a rigid foam material, provides high thermal resistance with an R-value typically ranging from 4.0 to 5.0 per inch, making it effective for moisture resistance and long-term durability. Fiberglass insulation, composed of fine glass fibers, offers an R-value of approximately 2.2 to 4.3 per inch, known for its flexibility and soundproofing qualities. Both materials are widely used in residential and commercial buildings to enhance energy efficiency, but their differing compositions influence installation methods and performance characteristics.

Key Properties of Polystyrene Insulation

Polystyrene insulation offers superior moisture resistance and high R-value per inch, making it ideal for energy-efficient applications where water exposure is a concern. Its rigid structure provides excellent compressive strength and durability compared to the more flexible yet less moisture-resistant fiberglass insulation. Polystyrene's closed-cell composition ensures minimal air permeability, enhancing thermal performance and reducing the risk of mold growth.

Key Properties of Fiberglass Insulation

Fiberglass insulation is known for its excellent thermal resistance, typically ranging from R-2.2 to R-2.7 per inch, making it highly effective in reducing heat transfer. Its non-combustible nature and resistance to moisture and mold enhance durability and indoor air quality. The material's soundproofing capabilities and affordability further contribute to its widespread use in residential and commercial insulation projects.

Thermal Efficiency: Polystyrene vs Fiberglass

Polystyrene insulation offers superior thermal resistance with an R-value ranging from 4.0 to 5.0 per inch, compared to fiberglass insulation which typically provides an R-value between 2.2 and 2.7 per inch. This higher R-value means polystyrene effectively reduces heat transfer, enhancing energy efficiency in buildings. Moreover, polystyrene's closed-cell structure provides better moisture resistance, maintaining thermal performance over time compared to the more porous fiberglass material.

Moisture Resistance Comparison

Polystyrene insulation offers superior moisture resistance compared to fiberglass insulation due to its closed-cell structure, preventing water absorption and reducing the risk of mold growth. Fiberglass insulation tends to trap moisture within its fibers, which can lead to decreased thermal performance and potential deterioration over time. Choosing polystyrene insulation is ideal in environments prone to high humidity or water exposure, ensuring long-term durability and energy efficiency.

Fire Safety and Flammability Ratings

Polystyrene insulation, classified as combustible with a typical flame spread rating of 75 to 200, requires fire-resistant coatings or barriers to enhance safety in building applications. In contrast, fiberglass insulation offers superior fire resistance, often achieving a flame spread rating below 25, as it is composed of non-combustible glass fibers. Choosing fiberglass insulation can significantly reduce fire hazards due to its inherent non-flammability and better compliance with fire safety codes.

Installation Methods and Ease of Use

Polystyrene insulation often comes in rigid foam panels that are easy to cut and fit precisely, making installation faster and cleaner compared to fiberglass insulation, which involves handling loose fibers requiring protective gear. Fiberglass insulation is typically installed using batts or rolls that conform to irregular spaces but can be itchy and more cumbersome to handle. Polystyrene's moisture resistance also simplifies installation in damp environments, reducing the need for additional vapor barriers.

Environmental Impact and Sustainability

Polystyrene insulation offers superior moisture resistance and durability, making it less prone to mold and decay compared to fiberglass insulation, which can degrade faster and release airborne fibers during installation and disposal. However, polystyrene is derived from non-renewable petroleum resources and poses challenges in recyclability due to its low density and chemical composition, contributing to environmental pollution if not properly managed. Fiberglass insulation, often made from recycled glass and sand, has a lower embodied energy footprint and is more environmentally sustainable when sourced and disposed of responsibly.

Cost Analysis: Polystyrene vs Fiberglass

Polystyrene insulation typically costs between $0.40 to $1.50 per square foot, making it a more expensive upfront option compared to fiberglass insulation, which ranges from $0.30 to $0.90 per square foot. Despite higher initial costs, polystyrene offers better moisture resistance and higher R-values per inch, potentially lowering long-term energy expenses. Fiberglass insulation is more affordable initially but may require more frequent replacement or maintenance due to susceptibility to moisture and reduced insulating performance over time.

Best Applications for Each Insulation Type

Polystyrene insulation excels in moisture resistance and is ideal for below-grade applications like foundation walls and crawl spaces, providing effective thermal protection in damp environments. Fiberglass insulation offers superior soundproofing and is best suited for attic floors, wall cavities, and ceilings where airflow and thermal regulation are critical. Selecting between polystyrene and fiberglass depends on specific project needs such as moisture exposure, thermal performance, and acoustic requirements.

Polystyrene Insulation vs Fiberglass Insulation Infographic

materialdif.com

materialdif.com