Polystyrene packaging offers superior rigidity and excellent insulation properties, making it ideal for protecting fragile items and maintaining temperature-sensitive products. In contrast, polyethylene packaging provides greater flexibility and moisture resistance, which enhances durability for shipping and storage applications. Choosing between polystyrene and polyethylene depends on the specific requirements for protection, insulation, and environmental impact.

Table of Comparison

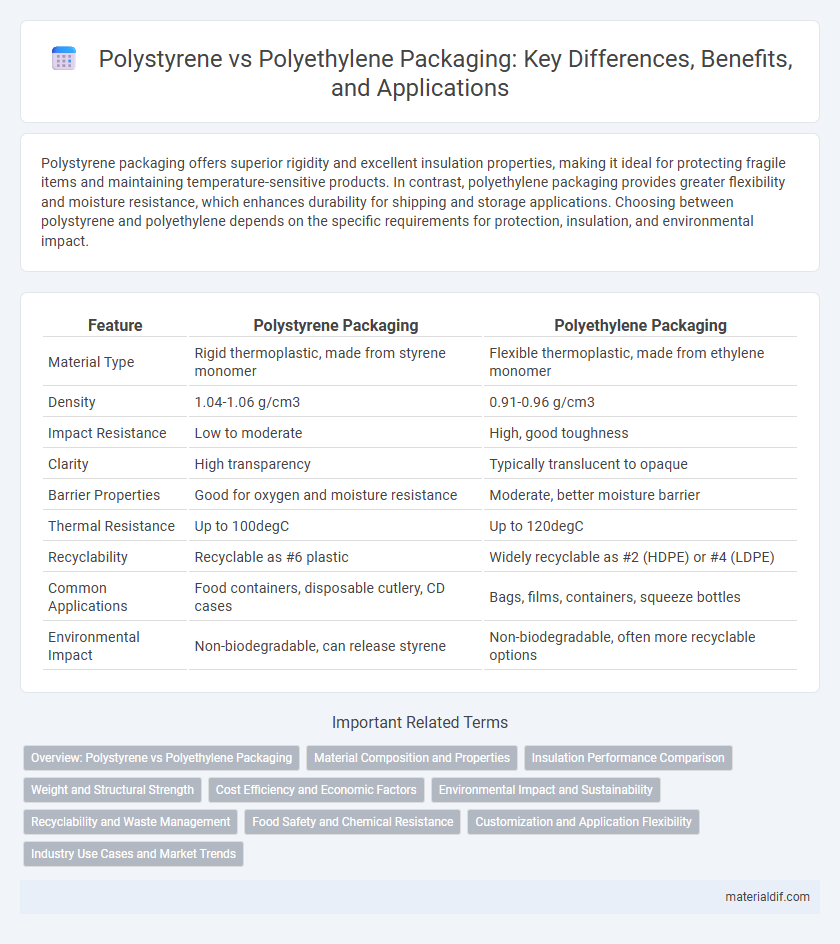

| Feature | Polystyrene Packaging | Polyethylene Packaging |

|---|---|---|

| Material Type | Rigid thermoplastic, made from styrene monomer | Flexible thermoplastic, made from ethylene monomer |

| Density | 1.04-1.06 g/cm3 | 0.91-0.96 g/cm3 |

| Impact Resistance | Low to moderate | High, good toughness |

| Clarity | High transparency | Typically translucent to opaque |

| Barrier Properties | Good for oxygen and moisture resistance | Moderate, better moisture barrier |

| Thermal Resistance | Up to 100degC | Up to 120degC |

| Recyclability | Recyclable as #6 plastic | Widely recyclable as #2 (HDPE) or #4 (LDPE) |

| Common Applications | Food containers, disposable cutlery, CD cases | Bags, films, containers, squeeze bottles |

| Environmental Impact | Non-biodegradable, can release styrene | Non-biodegradable, often more recyclable options |

Overview: Polystyrene vs Polyethylene Packaging

Polystyrene packaging offers rigidity and excellent insulation properties, making it ideal for protecting fragile items and maintaining temperature-sensitive products. Polyethylene packaging, however, is more flexible, moisture-resistant, and widely used for bags, films, and containers due to its durability and chemical resistance. Both materials serve key roles in packaging, with polystyrene favored for cushioning and thermal insulation, while polyethylene excels in versatility and environmental resilience.

Material Composition and Properties

Polystyrene packaging is composed of a rigid aromatic polymer derived from styrene monomers, offering excellent clarity, rigidity, and thermal insulation properties, making it ideal for food containers and protective packaging. Polyethylene packaging, primarily made from ethylene monomers, boasts high flexibility, chemical resistance, and moisture barrier properties, favoring applications like plastic bags and films. The distinct material compositions result in polystyrene being more brittle and transparent, whereas polyethylene provides greater durability and flexibility in packaging solutions.

Insulation Performance Comparison

Polystyrene packaging offers superior insulation performance compared to polyethylene packaging due to its closed-cell structure, which provides higher thermal resistance and reduces heat transfer effectively. Expanded polystyrene (EPS) and extruded polystyrene (XPS) maintain consistent temperature control, making them ideal for perishable goods and temperature-sensitive products. In contrast, polyethylene packaging typically exhibits lower insulation values, limiting its use in applications requiring stringent thermal protection.

Weight and Structural Strength

Polystyrene packaging offers higher rigidity and superior structural strength compared to polyethylene packaging, making it ideal for protecting fragile items during transit. Despite being generally heavier than polyethylene, polystyrene's durable nature reduces the need for additional cushioning materials, potentially balancing overall package weight. Polyethylene packaging, often lighter and more flexible, is preferred for applications where weight reduction and cost efficiency are prioritized over maximum structural strength.

Cost Efficiency and Economic Factors

Polystyrene packaging is generally more cost-effective for protective packaging and insulation due to its lower density and superior cushioning properties, reducing shipping damages and returns. Polyethylene packaging offers economic advantages in flexibility and recyclability, often resulting in lower production costs for lightweight, high-volume applications such as bags and shrink wrap. Evaluating the total cost of materials, manufacturing, and lifecycle impact reveals polystyrene's efficiency in specific uses, while polyethylene excels in cost savings through versatile processing and recycling infrastructure.

Environmental Impact and Sustainability

Polystyrene packaging, widely used for its rigidity and insulation properties, poses significant environmental challenges due to its non-biodegradable nature and low recycling rates, often contributing to persistent landfill waste and marine pollution. In contrast, polyethylene packaging, especially low-density polyethylene (LDPE), demonstrates better environmental performance with higher recyclability and the potential for reduction in carbon footprint through emerging bioplastic alternatives. Life cycle assessments reveal polyethylene's advantages in resource efficiency and end-of-life management, supporting its growing preference in sustainable packaging solutions.

Recyclability and Waste Management

Polystyrene packaging exhibits lower recyclability compared to polyethylene, largely due to its brittle nature and contamination issues during recycling processes. Polyethylene, especially high-density polyethylene (HDPE), is widely accepted in recycling programs and can be efficiently reprocessed into new packaging materials. Waste management initiatives favor polyethylene for its higher recycling rates and reduced environmental impact, while polystyrene often ends up in landfills due to limited recycling infrastructure.

Food Safety and Chemical Resistance

Polystyrene packaging offers superior rigidity and clarity, making it ideal for ready-to-eat foods, while its chemical resistance effectively prevents food contamination from external substances. Polyethylene packaging, known for its flexibility and moisture barrier properties, excels in protecting perishable items but may allow migration of certain additives under high temperatures. In terms of food safety, polystyrene's low permeability to oxygen and fats ensures better preservation of flavor and freshness compared to polyethylene.

Customization and Application Flexibility

Polystyrene packaging offers superior customization options with its ability to be molded into intricate shapes, making it ideal for protective packaging in electronics and fragile goods. Polyethylene packaging provides greater application flexibility due to its varied forms such as films, bags, and containers, widely used in food packaging and industrial products. Both materials serve distinct needs, with polystyrene excelling in rigidity and design precision, while polyethylene adapts to diverse packaging requirements through flexibility and durability.

Industry Use Cases and Market Trends

Polystyrene packaging is widely used in the food industry for its rigidity and excellent insulation properties, making it ideal for products like disposable cups and meat trays. In contrast, polyethylene packaging dominates the market for flexible applications such as plastic bags and shrink wraps, prized for its durability and moisture resistance. Current market trends show a growing demand for sustainable alternatives, driving innovation in biodegradable polystyrene and high-density polyethylene blends to meet environmental regulations.

Polystyrene Packaging vs Polyethylene Packaging Infographic

materialdif.com

materialdif.com