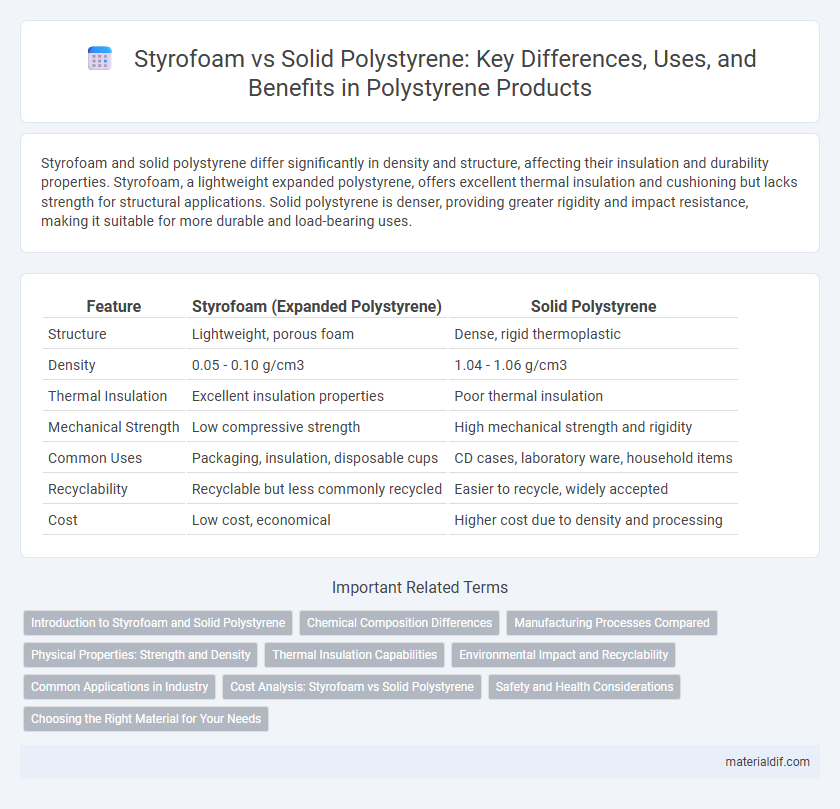

Styrofoam and solid polystyrene differ significantly in density and structure, affecting their insulation and durability properties. Styrofoam, a lightweight expanded polystyrene, offers excellent thermal insulation and cushioning but lacks strength for structural applications. Solid polystyrene is denser, providing greater rigidity and impact resistance, making it suitable for more durable and load-bearing uses.

Table of Comparison

| Feature | Styrofoam (Expanded Polystyrene) | Solid Polystyrene |

|---|---|---|

| Structure | Lightweight, porous foam | Dense, rigid thermoplastic |

| Density | 0.05 - 0.10 g/cm3 | 1.04 - 1.06 g/cm3 |

| Thermal Insulation | Excellent insulation properties | Poor thermal insulation |

| Mechanical Strength | Low compressive strength | High mechanical strength and rigidity |

| Common Uses | Packaging, insulation, disposable cups | CD cases, laboratory ware, household items |

| Recyclability | Recyclable but less commonly recycled | Easier to recycle, widely accepted |

| Cost | Low cost, economical | Higher cost due to density and processing |

Introduction to Styrofoam and Solid Polystyrene

Styrofoam, a trademarked form of expanded polystyrene foam, consists of lightweight, air-filled beads commonly used for insulation and packaging. Solid polystyrene is a rigid, transparent thermoplastic polymer widely employed in manufacturing containers, cutlery, and other durable goods. The key difference lies in Styrofoam's cellular structure offering superior insulating properties, while solid polystyrene provides mechanical strength and clarity.

Chemical Composition Differences

Styrofoam, a trademarked brand of expanded polystyrene (EPS), consists of 90-98% air trapped within polystyrene beads, giving it a lightweight, foamy structure. Solid polystyrene is a dense, rigid polymer made of styrene monomers polymerized into long hydrocarbon chains without the trapped air, resulting in a compact and transparent material. The fundamental chemical difference lies in the physical form, where Styrofoam's cellular structure incorporates air pockets, while solid polystyrene remains a continuous, non-porous polymer matrix.

Manufacturing Processes Compared

Styrofoam, a trademarked form of expanded polystyrene (EPS), is produced by expanding polystyrene beads with heat and steam, creating a lightweight, foam-like structure with air pockets that enhance insulation and cushioning properties. Solid polystyrene, in contrast, is manufactured via continuous polymerization and extrusion processes, resulting in a dense, rigid material with high mechanical strength and dimensional stability. The manufacturing of Styrofoam emphasizes expansion and foaming techniques for lightweight applications, whereas solid polystyrene manufacturing prioritizes uniform density and structural integrity for durable, versatile products.

Physical Properties: Strength and Density

Styrofoam, a foamed form of polystyrene, exhibits significantly lower density, typically around 0.05 g/cm3, compared to solid polystyrene's density of approximately 1.05 g/cm3. This low density in Styrofoam results in reduced compressive strength and rigidity, making it lightweight but less durable under mechanical stress. Solid polystyrene's denser, non-porous structure provides higher tensile strength and stiffness, suitable for applications requiring greater structural integrity.

Thermal Insulation Capabilities

Styrofoam, a branded form of expanded polystyrene foam, offers superior thermal insulation due to its closed-cell structure that traps air, significantly reducing heat transfer. Solid polystyrene, while more dense and structurally stable, has lower insulation efficiency because it lacks the air pockets that enhance thermal resistance in Styrofoam. This makes Styrofoam the preferred choice in applications requiring lightweight, high-performance thermal insulating materials such as building insulation and packaging.

Environmental Impact and Recyclability

Styrofoam, a trademarked form of expanded polystyrene foam, has a significant environmental impact due to its non-biodegradable nature and difficulty in recycling, often ending up in landfills or oceans where it persists for centuries. Solid polystyrene, while denser and less bulky than Styrofoam, offers better recyclability options through mechanical recycling processes that convert it back into usable plastic pellets, reducing environmental waste. Both materials contribute to plastic pollution, but solid polystyrene's recyclability presents a more sustainable solution when proper waste management systems are in place.

Common Applications in Industry

Styrofoam, a branded form of expanded polystyrene (EPS), is widely used for packaging, insulation, and disposable food containers due to its lightweight and cushioning properties. Solid polystyrene, known for its rigidity and clarity, finds applications in manufacturing durable consumer products, electronics housings, and precision components. Industries favor Styrofoam for thermal insulation and impact absorption, while solid polystyrene suits applications requiring structural strength and aesthetic appeal.

Cost Analysis: Styrofoam vs Solid Polystyrene

Styrofoam, a lightweight expanded polystyrene foam, generally costs less per cubic foot than solid polystyrene due to its lower material density and simplified manufacturing process. Solid polystyrene, while more expensive, offers higher durability and better structural integrity, making it cost-effective for applications requiring strength and longevity. The total cost analysis must consider not only the initial price but also factors like thermal insulation efficiency, weight-related transportation costs, and end-use performance to determine the more economical choice.

Safety and Health Considerations

Styrofoam, a brand of expanded polystyrene foam, presents safety concerns due to its potential release of toxic chemicals like styrene, especially when burned or heated, which can affect indoor air quality and pose health risks. Solid polystyrene is more stable and less likely to emit harmful substances under normal usage, making it safer for food packaging and everyday applications. Both materials require proper handling and disposal to minimize environmental and health impacts.

Choosing the Right Material for Your Needs

Styrofoam, a lightweight expanded polystyrene foam, excels in insulation and cushioning applications, making it ideal for packaging and thermal insulation. Solid polystyrene, a rigid and durable plastic, offers greater structural strength and is suitable for products requiring toughness and precision molding. Selecting between Styrofoam and solid polystyrene depends on factors like weight sensitivity, insulation properties, and mechanical strength requirements.

Styrofoam vs Solid Polystyrene Infographic

materialdif.com

materialdif.com