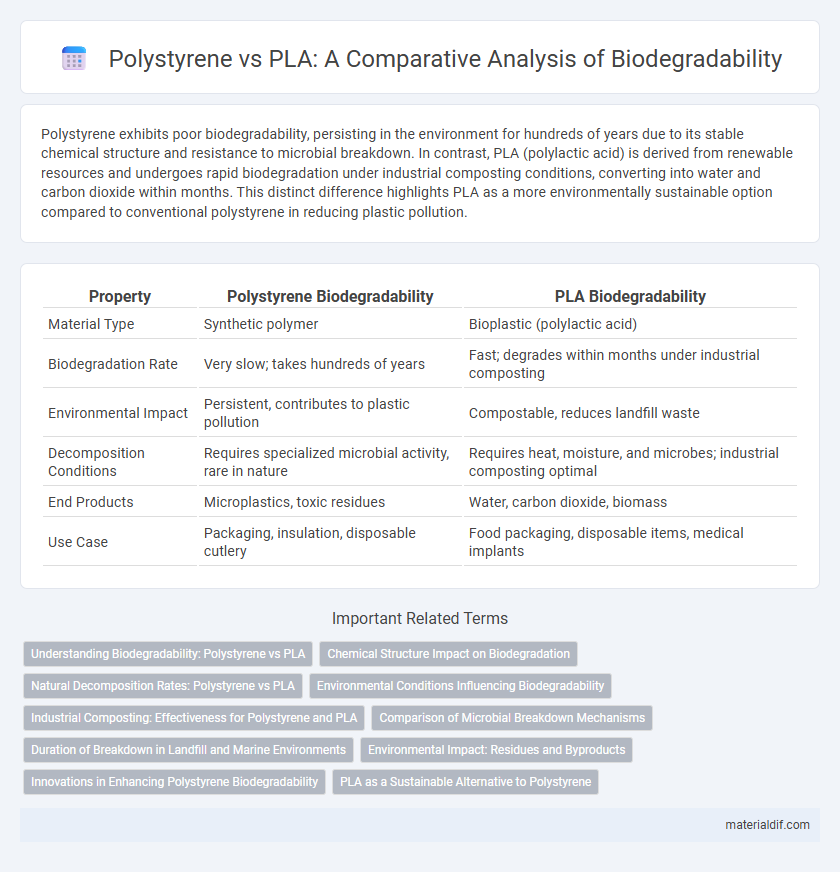

Polystyrene exhibits poor biodegradability, persisting in the environment for hundreds of years due to its stable chemical structure and resistance to microbial breakdown. In contrast, PLA (polylactic acid) is derived from renewable resources and undergoes rapid biodegradation under industrial composting conditions, converting into water and carbon dioxide within months. This distinct difference highlights PLA as a more environmentally sustainable option compared to conventional polystyrene in reducing plastic pollution.

Table of Comparison

| Property | Polystyrene Biodegradability | PLA Biodegradability |

|---|---|---|

| Material Type | Synthetic polymer | Bioplastic (polylactic acid) |

| Biodegradation Rate | Very slow; takes hundreds of years | Fast; degrades within months under industrial composting |

| Environmental Impact | Persistent, contributes to plastic pollution | Compostable, reduces landfill waste |

| Decomposition Conditions | Requires specialized microbial activity, rare in nature | Requires heat, moisture, and microbes; industrial composting optimal |

| End Products | Microplastics, toxic residues | Water, carbon dioxide, biomass |

| Use Case | Packaging, insulation, disposable cutlery | Food packaging, disposable items, medical implants |

Understanding Biodegradability: Polystyrene vs PLA

Polystyrene is a synthetic polymer with limited biodegradability, often persisting in the environment for hundreds of years, posing significant ecological challenges. In contrast, Polylactic Acid (PLA) is a biodegradable biopolymer derived from renewable resources like corn starch, capable of decomposing under industrial composting conditions within months. The key difference lies in molecular structure and microbial accessibility, making PLA a more sustainable alternative for reducing plastic pollution.

Chemical Structure Impact on Biodegradation

Polystyrene's chemical structure, consisting of a stable aromatic hydrocarbon backbone, significantly resists microbial degradation, resulting in poor biodegradability in natural environments. In contrast, polylactic acid (PLA) features ester linkages in its aliphatic polyester backbone, which are more susceptible to hydrolytic cleavage by enzymes, enhancing its biodegradation rate. The presence of aromatic rings in polystyrene hinders enzymatic attack, whereas PLA's simpler chemical bonds facilitate faster microbial assimilation and breakdown.

Natural Decomposition Rates: Polystyrene vs PLA

Polystyrene exhibits extremely slow natural decomposition rates, often taking hundreds to thousands of years to break down in the environment due to its complex synthetic polymer structure. In contrast, PLA (polylactic acid), derived from renewable resources like corn starch, biodegrades significantly faster under industrial composting conditions, typically within 1 to 6 months. The substantial difference in biodegradability highlights PLA's advantage in reducing long-term environmental pollution compared to conventional polystyrene.

Environmental Conditions Influencing Biodegradability

Polystyrene biodegradability is significantly slower than PLA under typical environmental conditions due to its resistant polymer structure, requiring high-temperature industrial composting or specialized microbial activity for degradation. PLA biodegrades more readily in controlled composting environments with temperatures above 58degC and sufficient humidity, enabling faster breakdown into water and carbon dioxide. Factors such as temperature, microbial presence, oxygen availability, and moisture levels critically influence the degradation rates of both polymers in natural and engineered settings.

Industrial Composting: Effectiveness for Polystyrene and PLA

Polystyrene exhibits poor biodegradability under industrial composting conditions, often persisting for decades without significant breakdown due to its synthetic polymer structure. In contrast, polylactic acid (PLA) undergoes effective biodegradation in industrial composting facilities, where controlled temperature and microbial activity promote its conversion into carbon dioxide and water within weeks. The difference in polymer composition renders industrial composting highly effective for PLA, while polystyrene remains largely resistant to such biodegradation processes.

Comparison of Microbial Breakdown Mechanisms

Polystyrene biodegradability involves microbial degradation primarily through specific strains of bacteria and fungi capable of breaking its long-chain hydrocarbon structure via oxidative and enzymatic pathways. In contrast, PLA (polylactic acid) undergoes microorganism-mediated hydrolysis and enzymatic cleavage of its ester linkages, resulting in faster and more efficient biodegradation under composting conditions. The microbial breakdown of PLA is generally more predictable and complete, while polystyrene requires longer periods and specialized microbial consortia due to its synthetic aromatic polymer backbone.

Duration of Breakdown in Landfill and Marine Environments

Polystyrene can take up to 500 years or more to biodegrade in landfill and marine environments due to its complex polymer structure and resistance to microbial attack. In contrast, polylactic acid (PLA) typically breaks down within 6 months to 2 years under industrial composting conditions but may persist longer in marine settings due to lower temperatures and limited microbial activity. The significant disparity in degradation durations highlights PLA's improved biodegradability over polystyrene in controlled environments, while both materials pose long-term persistence challenges in natural marine ecosystems.

Environmental Impact: Residues and Byproducts

Polystyrene biodegrades very slowly, often leaving behind microplastic residues that persist in the environment and contribute to long-term pollution. In contrast, PLA (polylactic acid) biodegrades more rapidly under industrial composting conditions, breaking down into water, carbon dioxide, and biomass with minimal harmful byproducts. The environmental impact of polystyrene residues is significant due to their toxicity and accumulation in ecosystems, whereas PLA residues generally pose a lower ecological risk.

Innovations in Enhancing Polystyrene Biodegradability

Innovations in enhancing polystyrene biodegradability include the development of bio-based additives and microbial treatments that accelerate polymer breakdown, offering a promising alternative to traditional non-degradable polystyrene. Recent research on enzyme engineering and incorporation of biodegradable copolymers has significantly improved polystyrene's environmental footprint compared to polylactic acid (PLA), which naturally biodegrades under industrial composting conditions. These advancements aim to bridge the gap between polystyrene's durability and sustainability, making it more comparable to PLA's widely recognized compostable properties.

PLA as a Sustainable Alternative to Polystyrene

Polylactic acid (PLA) exhibits significantly higher biodegradability compared to polystyrene, breaking down within months under industrial composting conditions, whereas polystyrene can persist for centuries in landfills. PLA's renewable biopolymer composition, derived from fermented plant starch such as corn or sugarcane, positions it as a sustainable alternative to petroleum-based polystyrene. This sustainability advantage reduces environmental pollution and carbon footprint, making PLA preferable for single-use packaging and disposable products.

Polystyrene biodegradability vs PLA biodegradability Infographic

materialdif.com

materialdif.com