Polystyrene foam cutting offers flexibility in creating custom shapes and prototypes with minimal tooling costs, making it ideal for small-scale or intricate designs. Injection molding of polystyrene pet provides high precision and consistency for mass production, delivering durable parts with smooth surface finishes. While foam cutting excels in rapid prototyping, injection molding is preferred for large-volume manufacturing due to its efficiency and reproducibility.

Table of Comparison

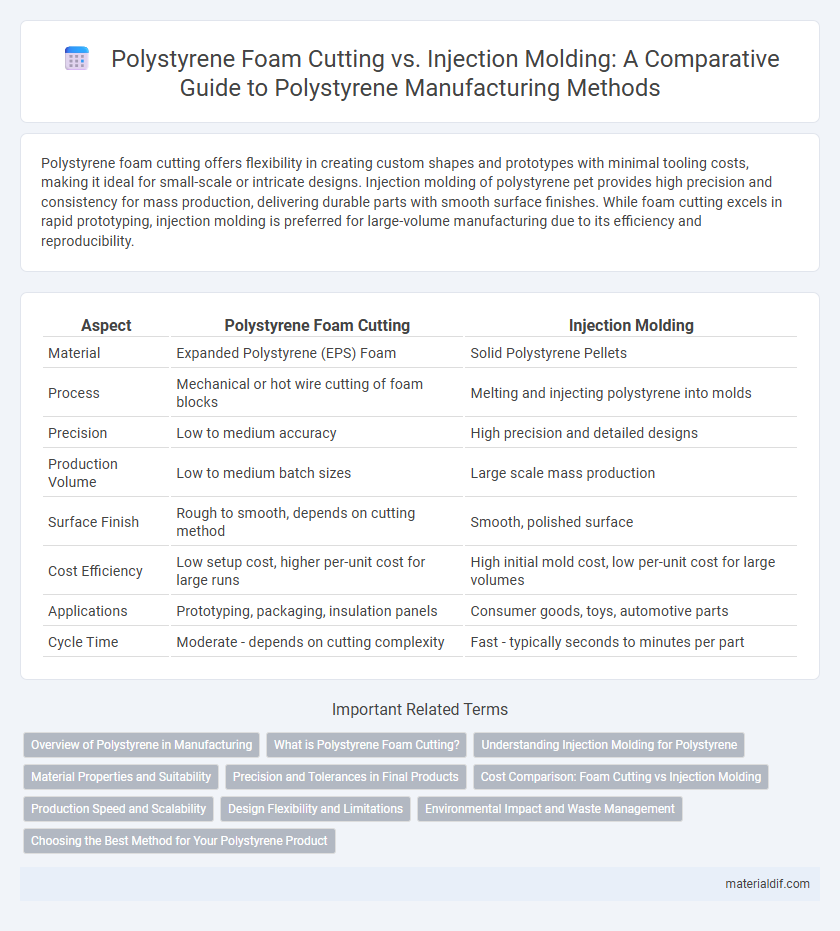

| Aspect | Polystyrene Foam Cutting | Injection Molding |

|---|---|---|

| Material | Expanded Polystyrene (EPS) Foam | Solid Polystyrene Pellets |

| Process | Mechanical or hot wire cutting of foam blocks | Melting and injecting polystyrene into molds |

| Precision | Low to medium accuracy | High precision and detailed designs |

| Production Volume | Low to medium batch sizes | Large scale mass production |

| Surface Finish | Rough to smooth, depends on cutting method | Smooth, polished surface |

| Cost Efficiency | Low setup cost, higher per-unit cost for large runs | High initial mold cost, low per-unit cost for large volumes |

| Applications | Prototyping, packaging, insulation panels | Consumer goods, toys, automotive parts |

| Cycle Time | Moderate - depends on cutting complexity | Fast - typically seconds to minutes per part |

Overview of Polystyrene in Manufacturing

Polystyrene foam cutting offers a cost-effective solution for creating lightweight, insulating components with complex shapes and minimal material waste, making it ideal for packaging and prototyping. Injection molding produces high-precision, durable polystyrene parts suitable for mass manufacturing in automotive, electronics, and consumer goods industries, leveraging rapid cycle times and detailed surface finishes. Both methods utilize polystyrene's thermoplastic properties, but serve distinct manufacturing needs based on product complexity, volume, and performance requirements.

What is Polystyrene Foam Cutting?

Polystyrene foam cutting is a precise shaping process used to form expanded polystyrene (EPS) or extruded polystyrene (XPS) materials into custom shapes and sizes, primarily for packaging, insulation, and architectural applications. This method employs hot wire cutters or CNC machines that melt through the foam with minimal residue, enabling smooth edges and intricate designs that are difficult to achieve with conventional cutting tools. Unlike injection molding, which shapes molten polystyrene into rigid parts through high pressure, foam cutting works on pre-formed lightweight sheets, making it ideal for prototyping and lightweight structural components.

Understanding Injection Molding for Polystyrene

Injection molding for polystyrene involves melting the polymer pellets and injecting the molten material into a precision-engineered mold, enabling the production of complex shapes with high dimensional accuracy and surface finish. Unlike polystyrene foam cutting, which shapes expanded polystyrene by mechanical means, injection molding allows for high-volume manufacturing with consistent quality and minimal material waste. This process is essential for creating durable, detailed parts used in packaging, automotive components, and consumer goods.

Material Properties and Suitability

Polystyrene foam offers excellent thermal insulation, low density, and ease of cutting, making it highly suitable for lightweight packaging and insulation applications. Injection molding of polystyrene produces dense, rigid, and dimensionally stable parts ideal for durable consumer goods and detailed components. The choice between foam cutting and injection molding depends on the required material strength, precision, and end-use performance.

Precision and Tolerances in Final Products

Polystyrene foam cutting offers limited precision with tolerances typically ranging around +-0.5 mm, making it suitable for prototypes or low-volume applications where detailed geometries are less critical. Injection molding of polystyrene achieves superior precision and tighter tolerances, often within +-0.1 mm, enabling consistent production of intricate parts with smooth finishes. The enhanced control in injection molding supports high-volume manufacturing requirements demanding exact dimensional accuracy and repeatability.

Cost Comparison: Foam Cutting vs Injection Molding

Polystyrene foam cutting offers a significantly lower initial investment compared to injection molding, which requires expensive molds and high setup costs. The per-unit cost for foam cutting remains economical for low to medium production volumes, while injection molding becomes cost-effective only at large-scale manufacturing due to its high upfront expenses but lower marginal costs. For projects needing rapid prototyping or short runs, foam cutting is more budget-friendly, whereas injection molding is preferred for mass production demanding consistent precision and durability.

Production Speed and Scalability

Polystyrene foam cutting offers rapid prototyping and low-volume production with flexible design adjustments but is limited in scalability due to slower manual or CNC processes. Injection molding enables high-speed production of consistent, complex parts at scale, making it ideal for mass manufacturing despite higher initial mold costs. Scalability in injection molding is enhanced through automation and multi-cavity molds, significantly outperforming foam cutting in production speed for large volumes.

Design Flexibility and Limitations

Polystyrene foam cutting offers high design flexibility by allowing intricate shapes and custom sizes to be created quickly with minimal tooling costs, ideal for prototypes and low-volume applications. Injection molding provides consistent precision and complex geometric details but involves higher upfront mold design costs and limits rapid design changes. While foam cutting excels in rapid customization, injection molding is better suited for mass production with tighter tolerances and complex features.

Environmental Impact and Waste Management

Polystyrene foam cutting generates significant amounts of non-biodegradable scrap that challenge waste management systems and contribute to landfill accumulation. Injection molding produces more precise shapes with less material waste, enabling better recycling opportunities and reducing environmental footprint. Both methods require improved recycling technologies to address persistent environmental pollution associated with polystyrene products.

Choosing the Best Method for Your Polystyrene Product

Polystyrene foam cutting offers precision and lower tooling costs, making it ideal for custom or low-volume production of lightweight, insulated products such as packaging or thermal panels. Injection molding provides high throughput and consistent quality, suitable for complex, durable items requiring intricate details or mass production like consumer goods and automotive components. Evaluating factors like production volume, design complexity, material properties, and budget constraints ensures selecting the most efficient manufacturing method for your polystyrene product.

Polystyrene foam cutting vs Injection molding Infographic

materialdif.com

materialdif.com