GPPS (General Purpose Polystyrene) offers excellent clarity and rigidity, making it ideal for packaging and display applications, while SAN (Styrene Acrylonitrile) provides enhanced chemical resistance and durability due to the acrylonitrile component. SAN's improved thermal stability and impact resistance make it suitable for more demanding environments compared to GPPS. Choosing between GPPS and SAN depends on the balance required between optical properties and mechanical performance in polystyrene PET products.

Table of Comparison

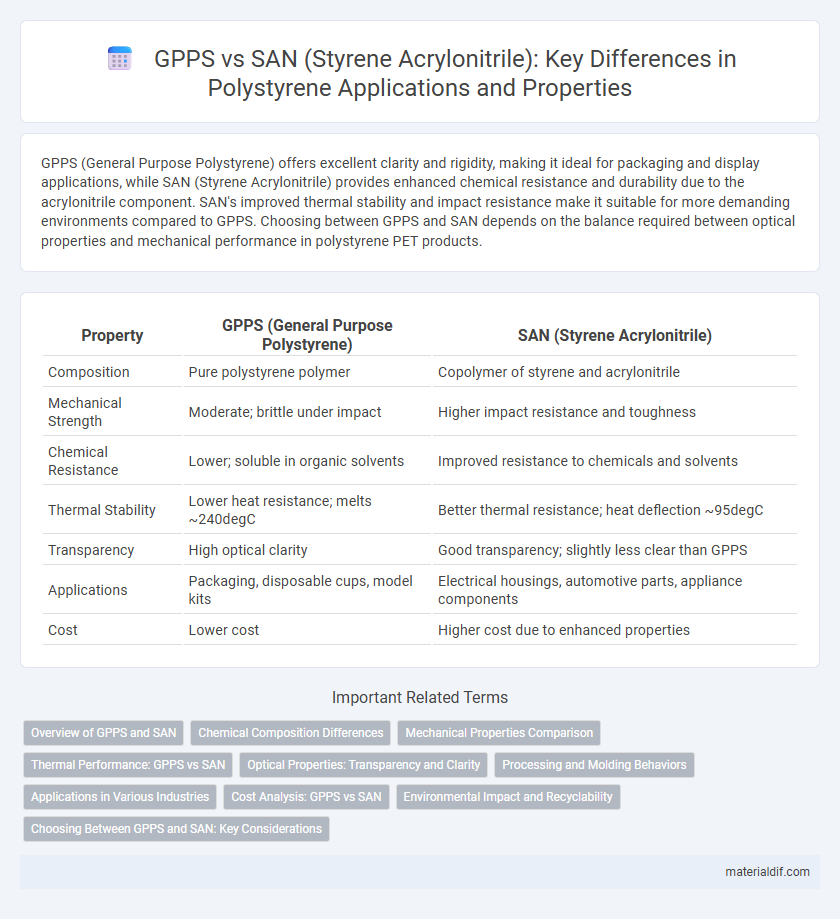

| Property | GPPS (General Purpose Polystyrene) | SAN (Styrene Acrylonitrile) |

|---|---|---|

| Composition | Pure polystyrene polymer | Copolymer of styrene and acrylonitrile |

| Mechanical Strength | Moderate; brittle under impact | Higher impact resistance and toughness |

| Chemical Resistance | Lower; soluble in organic solvents | Improved resistance to chemicals and solvents |

| Thermal Stability | Lower heat resistance; melts ~240degC | Better thermal resistance; heat deflection ~95degC |

| Transparency | High optical clarity | Good transparency; slightly less clear than GPPS |

| Applications | Packaging, disposable cups, model kits | Electrical housings, automotive parts, appliance components |

| Cost | Lower cost | Higher cost due to enhanced properties |

Overview of GPPS and SAN

GPPS (General Purpose Polystyrene) is a transparent, rigid thermoplastic known for its excellent clarity, ease of processing, and low cost, commonly used in packaging, disposable cutlery, and consumer products. SAN (Styrene Acrylonitrile) is a copolymer of styrene and acrylonitrile that offers higher chemical resistance, improved mechanical strength, and better thermal stability compared to GPPS. SAN's enhanced properties make it suitable for applications requiring durability and resistance to solvents, such as automotive components, household appliances, and medical devices.

Chemical Composition Differences

GPPS (General Purpose Polystyrene) consists primarily of styrene monomers polymerized into a rigid, transparent thermoplastic, exhibiting high clarity and ease of processing. SAN (Styrene Acrylonitrile) is a copolymer combining styrene with acrylonitrile, which imparts enhanced chemical resistance, heat tolerance, and mechanical strength compared to GPPS. The presence of acrylonitrile units in SAN alters the polymer chain polarity and intermolecular forces, resulting in improved durability and reduced brittleness.

Mechanical Properties Comparison

General Purpose Polystyrene (GPPS) exhibits higher rigidity and clarity but lower impact resistance compared to Styrene Acrylonitrile (SAN). SAN offers enhanced toughness, improved chemical resistance, and better dimensional stability due to the acrylonitrile component, making it more suitable for applications requiring mechanical stress endurance. The tensile strength of SAN typically ranges from 50 to 70 MPa, surpassing GPPS's 40 to 50 MPa, while SAN's improved elongation at break indicates superior flexibility.

Thermal Performance: GPPS vs SAN

GPPS exhibits a lower heat distortion temperature around 90-100degC, limiting its use in high-temperature applications, whereas SAN offers enhanced thermal stability with a heat distortion temperature typically between 105-115degC. SAN's improved thermal performance results from acrylonitrile units increasing rigidity and heat resistance compared to the amorphous structure of GPPS. This makes SAN more suitable for applications requiring better dimensional stability under elevated temperatures.

Optical Properties: Transparency and Clarity

General Purpose Polystyrene (GPPS) offers excellent clarity and high transparency due to its amorphous structure, making it ideal for applications demanding clear and visually appealing materials. Styrene Acrylonitrile (SAN) exhibits superior chemical resistance and slightly better thermal stability but typically has lower optical clarity and increased haze compared to GPPS. The copolymer composition of SAN affects its refractive index, resulting in reduced transparency relative to the highly transparent GPPS.

Processing and Molding Behaviors

General Purpose Polystyrene (GPPS) exhibits excellent flow properties and ease of molding due to its low viscosity and transparency, making it ideal for vacuum forming and injection molding applications. Styrene Acrylonitrile (SAN) copolymers demonstrate enhanced chemical resistance and thermal stability, requiring higher processing temperatures and offering improved dimensional stability during molding. The differential melt flow index between GPPS and SAN significantly affects cycle times and mold release behavior, influencing manufacturing efficiency and product performance.

Applications in Various Industries

GPPS (General Purpose Polystyrene) is extensively used in packaging, disposable cutlery, and insulation materials due to its clarity and ease of molding. SAN (Styrene Acrylonitrile) offers enhanced chemical resistance and mechanical strength, making it suitable for automotive parts, household appliances, and medical devices. Both polymers serve diverse industries by balancing cost-effectiveness and performance characteristics tailored to specific application needs.

Cost Analysis: GPPS vs SAN

General Purpose Polystyrene (GPPS) typically offers a lower cost per kilogram compared to Styrene Acrylonitrile (SAN) due to simpler polymerization processes and less expensive raw materials. SAN combines styrene and acrylonitrile, resulting in enhanced mechanical properties and chemical resistance that justify its higher price in specialized applications. Cost analysis reveals GPPS as more economical for mass-produced, low-stress items, while SAN is preferred for durability-demanding components despite elevated material expenses.

Environmental Impact and Recyclability

GPPS (General Purpose Polystyrene) and SAN (Styrene Acrylonitrile) differ significantly in environmental impact and recyclability, with GPPS being more widely recycled due to its simpler polymer structure and higher compatibility with existing recycling streams. SAN contains acrylonitrile, which enhances chemical resistance but complicates recycling processes and may release more persistent toxins during decomposition. Choosing GPPS over SAN can reduce environmental footprint, facilitating easier recycling and lowering long-term pollution risks.

Choosing Between GPPS and SAN: Key Considerations

When choosing between GPPS (General Purpose Polystyrene) and SAN (Styrene Acrylonitrile), consider their mechanical properties and chemical resistance; GPPS offers high clarity and ease of processing but lower impact strength, while SAN provides improved toughness and better resistance to solvents and heat. SAN's acrylonitrile content enhances its barrier properties, making it ideal for applications requiring durability and chemical exposure tolerance. Cost differences also impact the decision, with GPPS generally being more economical for applications prioritizing optical clarity over toughness.

GPPS vs SAN (Styrene Acrylonitrile) Infographic

materialdif.com

materialdif.com