Syndiotactic polystyrene exhibits a highly regular molecular arrangement, resulting in enhanced crystallinity and superior mechanical strength compared to atactic polystyrene, which has a random molecular structure that contributes to its amorphous and flexible nature. This structural difference significantly impacts thermal stability, with syndiotactic polystyrene delivering higher melting points and improved chemical resistance. These properties make syndiotactic polystyrene ideal for applications requiring durability and stability, whereas atactic polystyrene is preferred for uses prioritizing transparency and ease of processing.

Table of Comparison

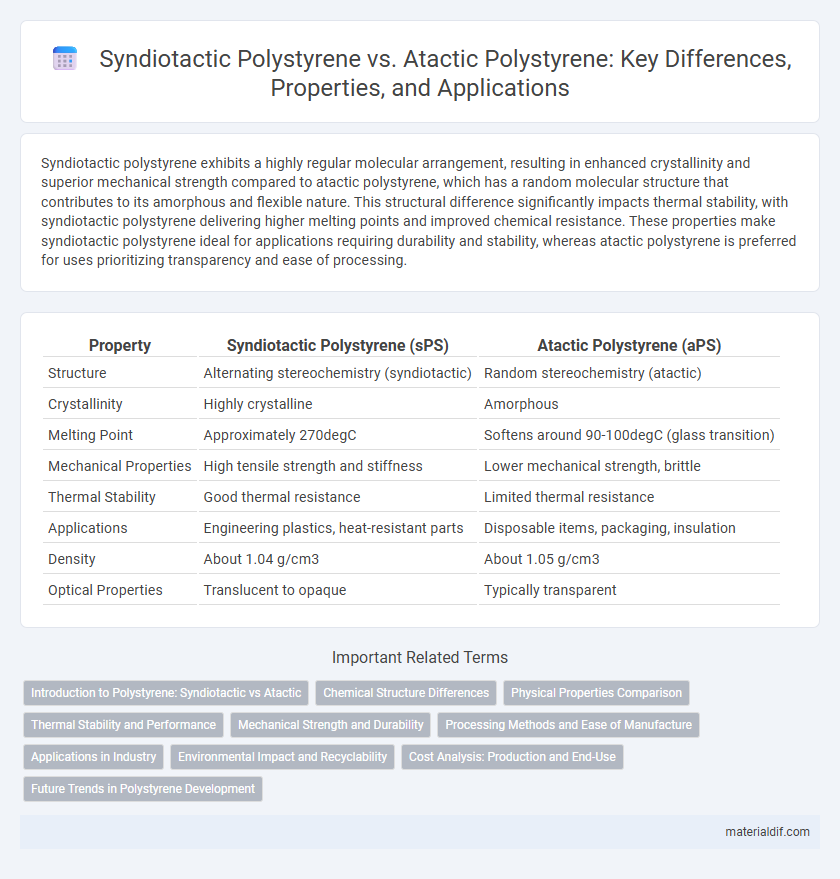

| Property | Syndiotactic Polystyrene (sPS) | Atactic Polystyrene (aPS) |

|---|---|---|

| Structure | Alternating stereochemistry (syndiotactic) | Random stereochemistry (atactic) |

| Crystallinity | Highly crystalline | Amorphous |

| Melting Point | Approximately 270degC | Softens around 90-100degC (glass transition) |

| Mechanical Properties | High tensile strength and stiffness | Lower mechanical strength, brittle |

| Thermal Stability | Good thermal resistance | Limited thermal resistance |

| Applications | Engineering plastics, heat-resistant parts | Disposable items, packaging, insulation |

| Density | About 1.04 g/cm3 | About 1.05 g/cm3 |

| Optical Properties | Translucent to opaque | Typically transparent |

Introduction to Polystyrene: Syndiotactic vs Atactic

Syndiotactic polystyrene (sPS) exhibits a regular alternating stereochemistry along its polymer chain, resulting in higher crystallinity, thermal stability, and mechanical strength compared to atactic polystyrene (aPS), which has a random, amorphous structure. The ordered arrangement in sPS enables enhanced chemical resistance and transparency, making it suitable for advanced engineering applications, while aPS is widely used in general-purpose products due to its ease of processing and lower cost. Understanding the structural differences between sPS and aPS is fundamental for tailoring polystyrene properties to specific industrial requirements such as packaging, automotive parts, and insulation materials.

Chemical Structure Differences

Syndiotactic polystyrene features an alternating arrangement of phenyl groups along the polymer backbone, resulting in a highly regular stereochemical pattern that enhances crystallinity. In contrast, atactic polystyrene has a random distribution of phenyl groups with no stereochemical order, leading to an amorphous, non-crystalline structure. This difference in tacticity directly affects the polymer's thermal stability, mechanical properties, and solubility.

Physical Properties Comparison

Syndiotactic polystyrene exhibits higher crystallinity and melting point, resulting in superior mechanical strength and thermal resistance compared to atactic polystyrene, which is amorphous and lacks a defined melting point. The regular stereochemical arrangement in syndiotactic polystyrene enhances its density and stiffness, while atactic polystyrene remains flexible with lower tensile strength due to random polymer chain configuration. These physical property differences make syndiotactic polystyrene suitable for high-performance applications, whereas atactic polystyrene is commonly used in packaging and insulation.

Thermal Stability and Performance

Syndiotactic polystyrene (sPS) exhibits superior thermal stability compared to atactic polystyrene (aPS) due to its highly regular molecular structure, which promotes crystallinity and elevates melting temperatures up to 270degC. This enhanced thermal resistance in sPS results in improved mechanical performance and chemical resistance under high-temperature conditions, making it suitable for advanced engineering applications. In contrast, atactic polystyrene lacks crystallinity, leading to lower glass transition temperatures around 100degC and reduced thermal stability, which limits its use in heat-exposed environments.

Mechanical Strength and Durability

Syndiotactic polystyrene exhibits higher mechanical strength and greater durability compared to atactic polystyrene due to its regular stereochemical arrangement, which enhances crystallinity and intermolecular interactions. Atactic polystyrene, with its irregular structure, remains largely amorphous, resulting in lower tensile strength and reduced resistance to environmental stress. The improved crystalline structure in syndiotactic polystyrene also provides better thermal stability and impact resistance, making it preferable for applications requiring robust performance.

Processing Methods and Ease of Manufacture

Syndiotactic polystyrene exhibits a highly regular polymer chain structure, enabling easier processing through injection molding and extrusion due to improved crystallinity and melting behavior. Atactic polystyrene, characterized by its random chain configuration, has a more amorphous nature, which leads to lower melting points and challenges in thermal processing, often requiring solvent-based methods or special additives. The enhanced thermal stability and rigidity of syndiotactic polystyrene facilitate the manufacture of high-performance parts with greater precision compared to the more flexible, less crystalline atactic variant.

Applications in Industry

Syndiotactic polystyrene (sPS) exhibits high crystallinity and thermal stability, making it ideal for applications in automotive parts, electrical insulation, and high-performance packaging. Atactic polystyrene (aPS), characterized by its amorphous nature and transparency, is widely used in consumer goods such as disposable cutlery, food containers, and insulation foams. Industrial processes select sPS for structural components requiring durability and heat resistance, while aPS is favored for lightweight, cost-effective, and moldable products.

Environmental Impact and Recyclability

Syndiotactic polystyrene (sPS) exhibits a more ordered molecular structure that enhances its thermal stability and allows for more efficient recycling processes compared to atactic polystyrene (aPS), which is amorphous and less thermally stable. The improved crystallinity of sPS facilitates easier separation and reprocessing, reducing environmental impact by lowering degradation rates and increasing recyclability in industrial applications. In contrast, aPS's irregular structure leads to higher susceptibility to degradation and limited recyclability, contributing to greater environmental pollution and waste management challenges.

Cost Analysis: Production and End-Use

Syndiotactic polystyrene (sPS) typically incurs higher production costs due to its complex polymerization process involving specialized metallocene catalysts, which results in superior thermal and mechanical properties compared to atactic polystyrene (aPS). Atactic polystyrene, produced by simpler free radical polymerization, is cheaper but offers lower performance, making it suitable for cost-sensitive applications such as packaging and disposable items. The end-use cost-benefit analysis favors sPS for high-value sectors like automotive and electronics, where durability and heat resistance justify the premium, whereas aPS dominates markets prioritizing affordability.

Future Trends in Polystyrene Development

Syndiotactic polystyrene (sPS) exhibits superior thermal stability, crystallinity, and mechanical strength compared to atactic polystyrene (aPS), driving its growing adoption in high-performance applications. Future trends in polystyrene development emphasize enhancing sPS production efficiency through advanced catalytic systems and sustainable polymerization processes. Research focus continues on tailoring sPS molecular structures for improved recyclability and integration in smart materials, positioning it as a key material in next-generation polymer technologies.

Syndiotactic polystyrene vs Atactic polystyrene Infographic

materialdif.com

materialdif.com