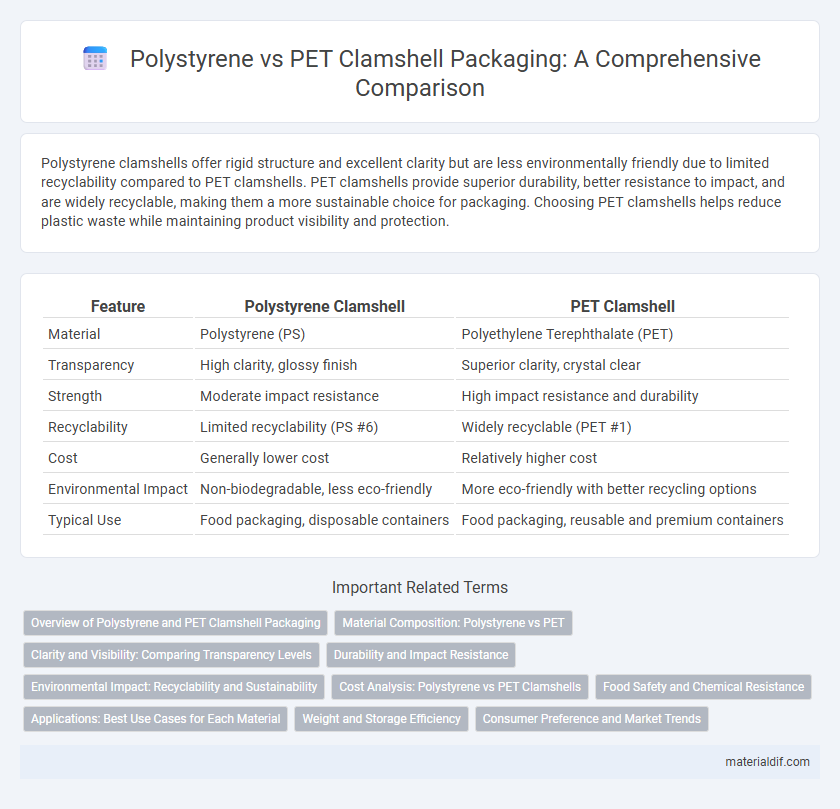

Polystyrene clamshells offer rigid structure and excellent clarity but are less environmentally friendly due to limited recyclability compared to PET clamshells. PET clamshells provide superior durability, better resistance to impact, and are widely recyclable, making them a more sustainable choice for packaging. Choosing PET clamshells helps reduce plastic waste while maintaining product visibility and protection.

Table of Comparison

| Feature | Polystyrene Clamshell | PET Clamshell |

|---|---|---|

| Material | Polystyrene (PS) | Polyethylene Terephthalate (PET) |

| Transparency | High clarity, glossy finish | Superior clarity, crystal clear |

| Strength | Moderate impact resistance | High impact resistance and durability |

| Recyclability | Limited recyclability (PS #6) | Widely recyclable (PET #1) |

| Cost | Generally lower cost | Relatively higher cost |

| Environmental Impact | Non-biodegradable, less eco-friendly | More eco-friendly with better recycling options |

| Typical Use | Food packaging, disposable containers | Food packaging, reusable and premium containers |

Overview of Polystyrene and PET Clamshell Packaging

Polystyrene clamshell packaging offers lightweight, rigid protection ideal for insulating and cushioning food products, with excellent clarity and cost-effectiveness. PET clamshell packaging provides superior impact resistance, clarity, and recyclability, making it suitable for premium food display and environmentally conscious consumers. Both materials are widely used in food packaging but differ significantly in durability, environmental impact, and cost considerations.

Material Composition: Polystyrene vs PET

Polystyrene clamshell packaging is made from a synthetic aromatic polymer derived from styrene, offering rigidity, clarity, and cost-effectiveness but lower impact resistance compared to PET clamshells. PET clamshells consist of polyethylene terephthalate, a thermoplastic polymer known for superior strength, higher impact resistance, and recyclability, making it more eco-friendly. The material composition difference results in distinct performance attributes: polystyrene provides excellent cosmetic clarity, while PET delivers enhanced durability and sustainability benefits.

Clarity and Visibility: Comparing Transparency Levels

Polystyrene clamshells offer exceptional clarity and high transparency, making them ideal for showcasing products with vibrant colors and intricate details. PET clamshells provide good transparency but often appear slightly less clear due to their inherent material structure, which can affect product visibility. The superior optical clarity of polystyrene enhances consumer appeal by delivering sharper and more vivid visual presentation compared to PET alternatives.

Durability and Impact Resistance

Polystyrene clamshells offer high rigidity but are more brittle, resulting in lower impact resistance compared to PET clamshells, which provide greater flexibility and superior durability under stress. PET clamshells maintain structural integrity during drops and impacts, reducing the risk of cracking or breaking, while polystyrene tends to shatter under similar conditions. This enhanced impact resistance makes PET clamshells a preferred choice for packaging fragile or heavy products requiring reliable protection.

Environmental Impact: Recyclability and Sustainability

Polystyrene clamshells are less environmentally friendly than PET clamshells due to their limited recyclability and slower decomposition rates, contributing significantly to landfill waste. PET clamshells offer higher recyclability in municipal recycling programs, supporting circular economy practices and reducing environmental footprint. Sustainability efforts increasingly favor PET over polystyrene to minimize pollution and promote resource-efficient packaging solutions.

Cost Analysis: Polystyrene vs PET Clamshells

Polystyrene clamshells typically offer a lower cost per unit compared to PET clamshells due to cheaper raw materials and simpler manufacturing processes. PET clamshells have higher material costs but provide better durability and recyclability, which may reduce long-term expenses in waste management. Cost analysis should consider not only initial purchase price but also factors such as lifecycle, environmental impact, and end-of-life disposal savings.

Food Safety and Chemical Resistance

Polystyrene clamshell containers offer excellent food safety due to their inert nature, preventing food contamination and preserving taste. PET clamshells provide superior chemical resistance, effectively withstanding oils and acidic foods without degrading or leaching chemicals. For applications requiring durability against food acids and oils, PET is preferred, while polystyrene excels in maintaining food purity and clarity.

Applications: Best Use Cases for Each Material

Polystyrene clamshells excel in protecting lightweight, delicate food items such as bakery goods and small produce due to their rigid structure and insulating properties. PET clamshells are ideal for fresh fruits, salads, and ready-to-eat meals because of their clarity, impact resistance, and ability to showcase product freshness. Both materials suit food packaging but choosing between polystyrene and PET depends on the need for durability, transparency, and food safety standards.

Weight and Storage Efficiency

Polystyrene clamshells are significantly lighter than PET clamshells, enhancing portability and reducing shipping costs. Their rigid structure allows for efficient stacking, optimizing storage space in warehouses and retail displays. PET clamshells, while heavier, offer better durability but require more storage room due to less compact stacking capabilities.

Consumer Preference and Market Trends

Consumer preference for polystyrene clamshells remains strong in food packaging due to their superior insulation and cost-effectiveness, while PET clamshells gain traction for their clarity and recyclability. Market trends indicate a gradual shift toward PET clamshells driven by increasing environmental awareness and stricter regulations on single-use plastics. Despite this, polystyrene continues to dominate sectors prioritizing durability and thermal insulation, maintaining significant market share globally.

Polystyrene Clamshell vs PET Clamshell Infographic

materialdif.com

materialdif.com