Polystyrene injection molding offers precise, complex shapes with excellent structural integrity, ideal for detailed, high-volume production. Polystyrene thermoforming, on the other hand, provides cost-effective, rapid fabrication suitable for larger, simpler designs by heating and shaping sheets. Choosing between these methods depends on the required detail, production scale, and application of the polystyrene PET product.

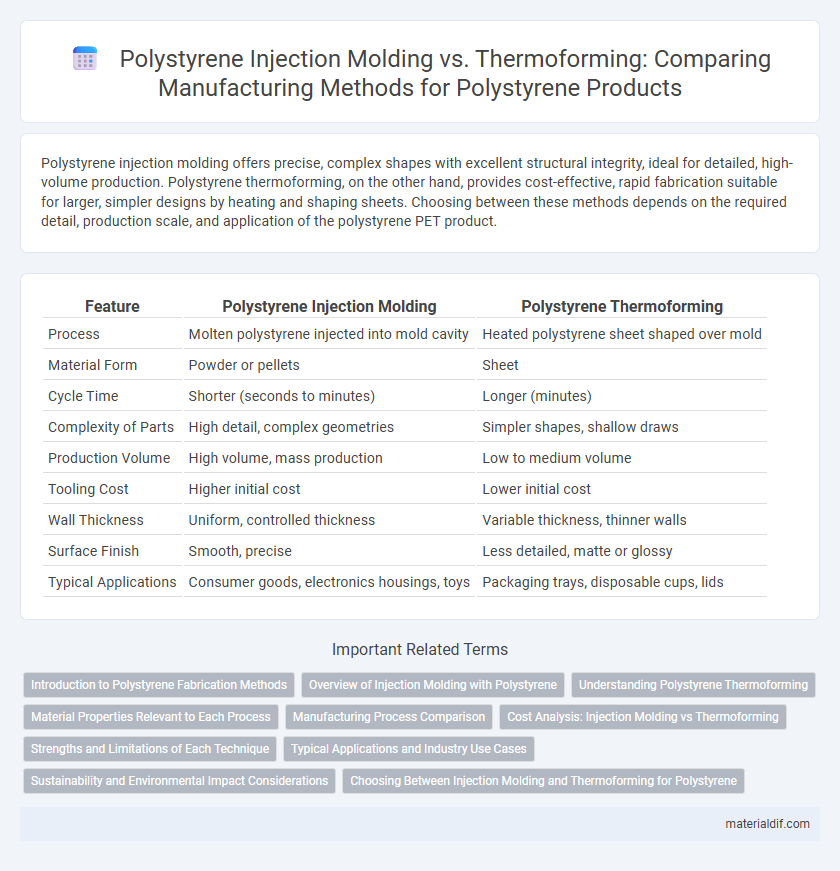

Table of Comparison

| Feature | Polystyrene Injection Molding | Polystyrene Thermoforming |

|---|---|---|

| Process | Molten polystyrene injected into mold cavity | Heated polystyrene sheet shaped over mold |

| Material Form | Powder or pellets | Sheet |

| Cycle Time | Shorter (seconds to minutes) | Longer (minutes) |

| Complexity of Parts | High detail, complex geometries | Simpler shapes, shallow draws |

| Production Volume | High volume, mass production | Low to medium volume |

| Tooling Cost | Higher initial cost | Lower initial cost |

| Wall Thickness | Uniform, controlled thickness | Variable thickness, thinner walls |

| Surface Finish | Smooth, precise | Less detailed, matte or glossy |

| Typical Applications | Consumer goods, electronics housings, toys | Packaging trays, disposable cups, lids |

Introduction to Polystyrene Fabrication Methods

Polystyrene injection molding involves melting polystyrene pellets and injecting the molten material into a mold cavity to form precise, high-strength parts with complex geometries. Polystyrene thermoforming heats polystyrene sheets until pliable and then shapes them over a mold using vacuum or pressure, ideal for lightweight, thin-walled products like packaging and trays. Both fabrication methods optimize polystyrene's versatility in manufacturing, balancing cost-efficiency, production speed, and material characteristics for diverse industrial applications.

Overview of Injection Molding with Polystyrene

Polystyrene injection molding involves melting polystyrene pellets and injecting the molten material into precision-engineered molds under high pressure, producing complex, detailed, and high-strength parts with excellent dimensional accuracy. This process is highly efficient for mass production of durable components used in automotive, electronics, and packaging industries due to its rapid cycle times and minimal material waste. The material's low melting point and good flow characteristics make it ideal for intricate designs, ensuring consistent surface finish and mechanical properties in finished products.

Understanding Polystyrene Thermoforming

Polystyrene thermoforming involves heating polystyrene sheets until pliable, then molding them to precise shapes using vacuum or pressure forming techniques, making it ideal for producing lightweight, rigid, and detailed packaging components. This process offers cost-effective scalability and rapid turnaround for large volume applications compared to injection molding, which requires complex molds and longer cycle times. Understanding thermoforming's advantages in design flexibility and reduced tooling expenses is crucial for selecting the optimal manufacturing method for polystyrene products.

Material Properties Relevant to Each Process

Polystyrene's rigidity and low melting point make it highly suitable for injection molding, where precise, detailed parts are required with consistent thickness and high dimensional stability. In contrast, the thermoforming process benefits from polystyrene's excellent thermo-plasticity and moderate heat resistance, allowing sheets to be easily heated and formed into larger, less complex shapes with varied thickness. Both processes leverage polystyrene's clarity and chemical resistance, but injection molding favors high mechanical strength while thermoforming excels in versatile design adaptability.

Manufacturing Process Comparison

Polystyrene injection molding involves melting granules and injecting the molten polymer into a mold cavity under high pressure, producing precise, complex shapes with consistent wall thickness and minimal finishing requirements. Thermoforming heats polystyrene sheets until pliable, then forms them over molds using vacuum or pressure, suitable for larger, thinner parts but with less detail and structural strength compared to injection molding. Injection molding offers faster cycle times and higher production volumes, while thermoforming is more cost-effective for prototyping and short-run manufacturing of simpler designs.

Cost Analysis: Injection Molding vs Thermoforming

Polystyrene injection molding typically incurs higher initial tooling costs ranging from $10,000 to $100,000 due to the need for precision steel molds, whereas thermoforming tooling costs are lower, often between $1,000 and $10,000, utilizing simpler molds. In terms of per-unit production costs, injection molding benefits from economies of scale, reducing costs significantly for volumes exceeding 10,000 units, while thermoforming maintains moderate per-unit expenses better suited for smaller to medium production runs. Maintenance and cycle times also influence cost, with injection molding offering faster cycles of 15-60 seconds per part, lowering labor costs over high volumes compared to thermoforming's longer cycle times of 30 seconds to several minutes.

Strengths and Limitations of Each Technique

Polystyrene injection molding offers precise dimensional accuracy and high production efficiency, making it ideal for complex, detailed parts with consistent quality. However, it requires significant upfront tooling costs and longer lead times compared to thermoforming. Polystyrene thermoforming excels in producing large, thin-walled parts with lower tooling expenses and faster turnaround but has limitations in achieving intricate geometries and reduced mechanical strength versus injection molded components.

Typical Applications and Industry Use Cases

Polystyrene injection molding is widely used for manufacturing complex, high-precision items such as medical device components, consumer electronics housings, and automotive parts due to its ability to create detailed and durable shapes. Polystyrene thermoforming excels in producing lightweight, large-surface packaging like food containers, disposable trays, and retail display units, favored for its cost efficiency and rapid production. Industries including healthcare, automotive, food packaging, and consumer goods leverage these processes based on product complexity, volume requirements, and material performance.

Sustainability and Environmental Impact Considerations

Polystyrene injection molding produces less material waste compared to polystyrene thermoforming, which involves trimming excess sheets and generates higher scrap rates. Injection molding allows for precise control over material use and energy efficiency during production, resulting in a smaller carbon footprint. Thermoforming's reliance on large polystyrene sheets contributes to increased environmental impact due to higher raw material consumption and limited recyclability of trimmed waste.

Choosing Between Injection Molding and Thermoforming for Polystyrene

Polystyrene injection molding offers precise, high-volume production with complex geometries and tight tolerances, making it ideal for durable and detailed components. Polystyrene thermoforming provides cost-effective, fast fabrication for large, thin-walled parts such as trays and packaging, emphasizing flexibility in design with lower tooling costs. Selecting between injection molding and thermoforming depends on production volume, part complexity, wall thickness requirements, and budget constraints for polystyrene applications.

Polystyrene Injection Molding vs Polystyrene Thermoforming Infographic

materialdif.com

materialdif.com